Table of Contents

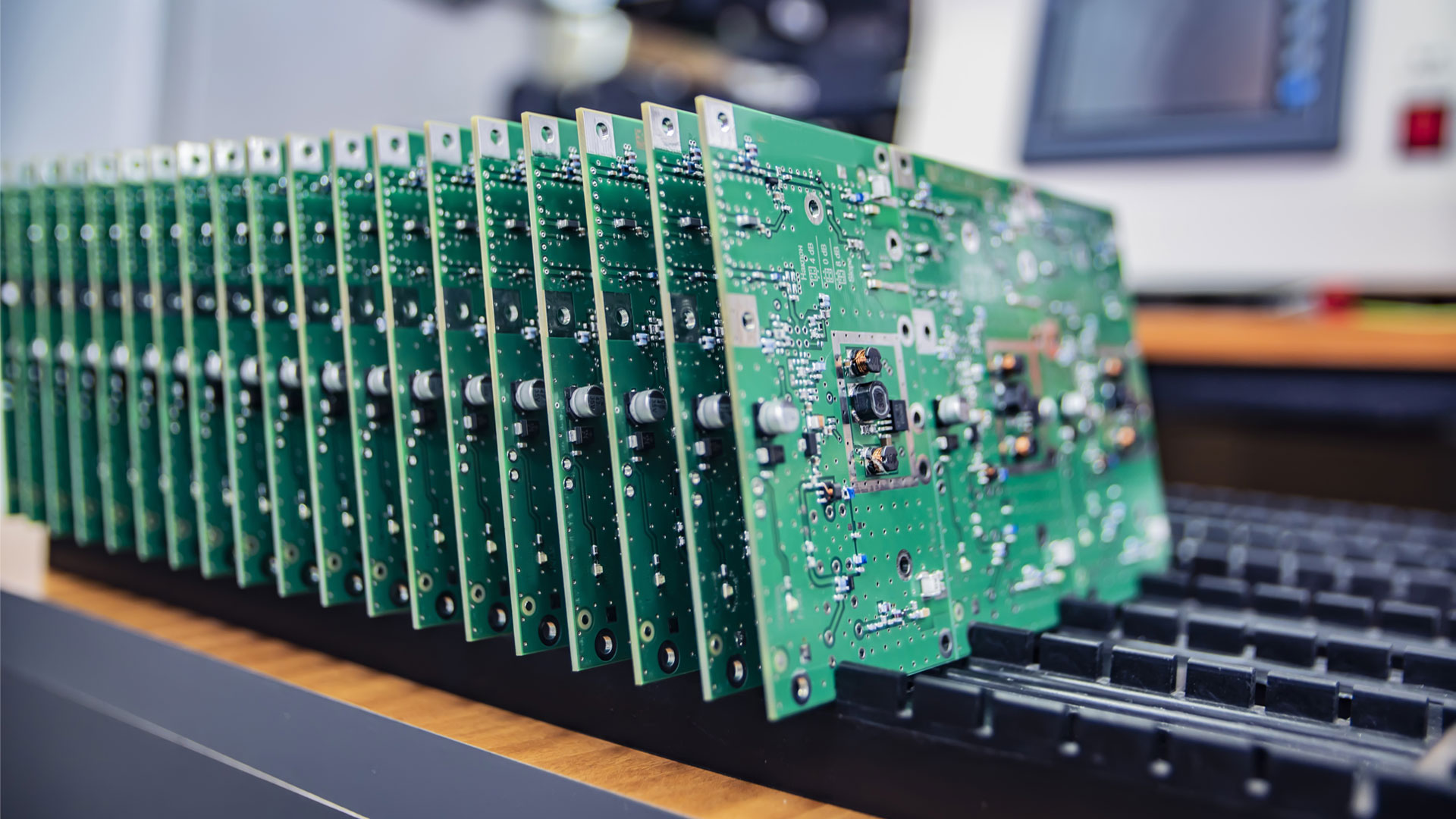

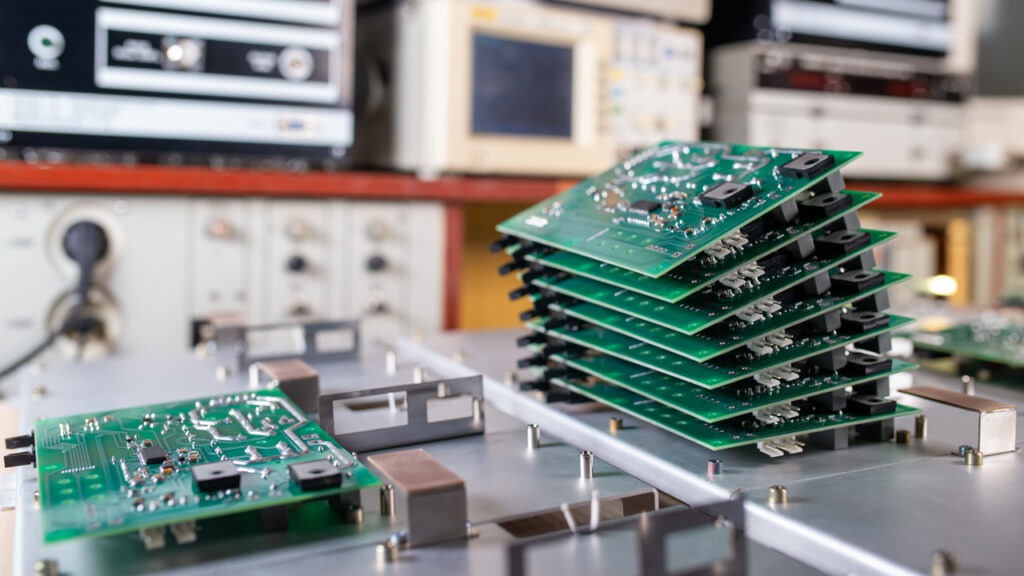

Emerging trends and process innovations redefining PCB assembly

PCB assembly is becoming more demanding as electronics continue to evolve toward higher performance, greater miniaturization, and increased reliability requirements. For OEMs, understanding current PCB assembly trends is critical not only for successful production but also for reducing risk across design, quality, and supply chain functions.

As we move into 2026, several technical and operational trends are shaping how electronics manufacturing services providers support OEM programs. These trends reflect real changes on the production floor, in quality systems, and throughout the component supply chain.

Increasing Design Density and Mixed Technology Assemblies

PCB designs are becoming more complex across nearly every industry. Higher component density, finer pitch devices, and increased use of mixed technology assemblies are now common rather than exceptional.

Boards frequently combine fine pitch surface mount (SMT) components, large thermal mass devices, press fit connectors, and through-hole parts on the same assembly. These designs place additional demands on solder paste deposition, placement accuracy, thermal profiling, and inspection capability.

From a manufacturing perspective, tighter tolerances increase sensitivity to process variation. Paste aperture design, stencil thickness, reflow profile optimization, and board support strategies all become more critical. OEMs that engage manufacturing partners early can validate that design choices are compatible with stable, repeatable assembly processes before releasing to production.

Advanced Process Control and Data-Driven Manufacturing

Automation in PCB assembly is no longer limited to placement speed. Leading manufacturers are investing in closed-loop process control and data collection across the assembly line.

Solder paste inspection systems measure volume, height, and area to identify trends that can indicate stencil wear, alignment issues, or material variability. AOI systems are increasingly used not only to detect defects, but also to provide statistical insight into process drift. This data enables corrective action before defects propagate downstream.

For OEMs, this shift toward data-driven manufacturing improves consistency and provides objective evidence of process capability. It also supports continuous improvement initiatives and more effective root cause analysis when issues arise.

Testing Strategies Are Becoming More Layered and Product Specific

Testing in PCB assembly is moving away from one-size-fits-all approaches. As product complexity increases, manufacturers are implementing layered testing strategies that align with product risk and end-use requirements.

Circuit testing remains valuable for verifying component placement, orientation, and electrical integrity at the board level. Flying probe testing offers flexibility for lower volume or frequently changing designs. Functional testing validates that the PCB assembly performs as intended under real operating conditions.

Environmental and stress testing are also being applied earlier for mission-critical applications. Thermal cycling, vibration, and burn-in testing help identify latent defects that may not be detected through electrical testing alone.

OEMs benefit most when testing strategies are defined collaboratively, balancing coverage, cost, and production volume.

Thermal Management and Material Considerations

Higher power densities are driving increased focus on thermal management at both the design and assembly stages. Use of metal core boards, heavy copper layers, thermal vias, and specialized substrates is becoming more common.

These materials introduce additional assembly considerations. Thermal mass variation affects reflow profiles and solder joint formation. Improper thermal management during assembly can lead to voiding, insufficient wetting, or reliability issues over time.

Manufacturers with experience handling advanced PCB materials can help OEMs validate assembly processes and avoid long-term performance risks.

Supply Chain Constraints Influence Assembly Decisions

Component availability continues to impact PCB assembly planning. Long lead time components, lifecycle transitions, and allocation risks require more proactive management.

OEMs are increasingly relying on EMS partners to support alternate part qualification, form fit function analysis, and approved vendor list development. These activities directly influence PCB assembly process stability and reduce the likelihood of last-minute changes that introduce risk.

Early alignment between engineering, sourcing, and manufacturing teams is critical to maintaining the schedule and product integrity.

Traceability Expectations Are Expanding

Traceability has become a foundational requirement for many OEMs, particularly in regulated and high-reliability markets. Expectations now extend beyond lot level tracking to include serial level traceability, process parameters, and test results.

Modern PCB assembly operations integrate traceability systems that link materials, machine data, inspection results, and operator actions throughout the manufacturing flow. This level of visibility supports compliance, warranty analysis, and long-term product support.

For OEMs, robust traceability reduces risk and improves confidence in manufacturing outcomes.

What These Trends Mean for OEMs

PCB assembly trends in 2026 point to a clear reality. Manufacturing success depends on technical alignment, process discipline, and early collaboration.

OEMs that treat their EMS partner as an extension of their engineering and quality teams are better positioned to manage complexity, maintain yield, and scale production reliably. Early engagement enables design decisions that support manufacturability, testability, and long-term reliability.

At Foxtronics EMS, we work closely with OEM teams to apply these trends in practical, production-ready ways. From advanced PCB assembly processes and layered testing strategies to supply chain support and traceability systems, our focus is on helping customers build reliable electronics with confidence.

Stay ahead of 2026 PCB assembly trends—partner with Foxtronics EMS for reliable PCB assembly manufacturing, quality assurance, and supply chain resilience.