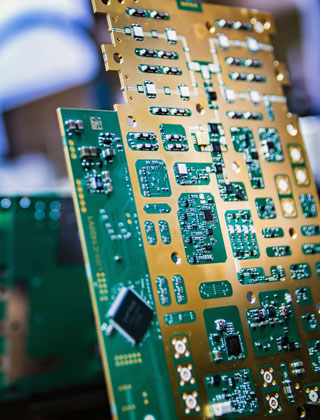

Precision PCB Assembly Services You Can Rely On

PCBA Manufacturing Services for Tomorrow’s Technology

We build high-performance PCB assemblies, box builds, and electronics systems engineered to meet complex specs, tight timelines, and evolving market demands.

Precision PCB Assembly Services You Can Rely On

PCBA Manufacturing Services for Tomorrow’s Technology

We build high-performance PCB assemblies, box builds, and electronics systems engineered to meet complex specs, tight timelines, and evolving market demands.

Explore Our Services

Proven Expertise Across Critical Industries

Serving Aerospace, Medical Devices, Robotics & More

With over 116 years of combined experience, we deliver mission-critical electronics with the reliability, compliance, and traceability your industry demands.

Proven Expertise Across Critical Industries

Serving Aerospace, Medical Devices, Robotics & More

With over 116 years of combined experience, we deliver mission-critical electronics with the reliability, compliance, and traceability your industry demands.

Explore All Industries

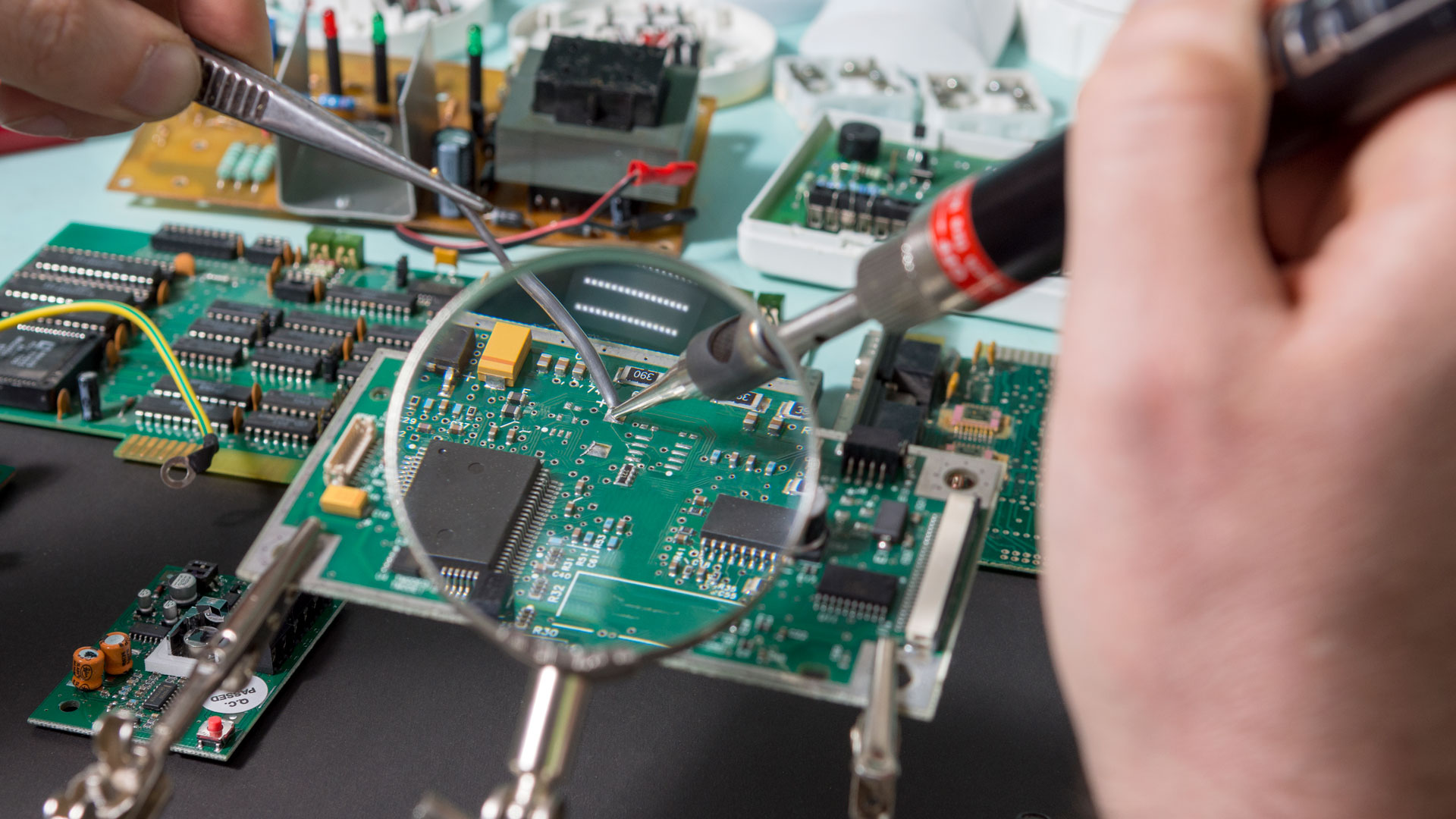

Rapid Prototyping to High-Volume Production

End-to-End EMS Solutions That Grow With Your Product

Accelerate your product development with rapid prototyping, scalable assembly, and high-volume production all under one experienced EMS partner.

Rapid Prototyping to High-Volume Production

End-to-End EMS Solutions That Grow With Your Product

Accelerate your product development with rapid prototyping, scalable assembly, and high-volume production all under one experienced EMS partner.

Request A Quote

Driving Innovation in Electronics Manufacturing

An EMS Partner Focused on Quality, Integrity & Innovation

Driven by innovation and supported by cross-functional teams, we help bring today’s most ambitious electronic products to life—from design to delivery.

Driving Innovation in Electronics Manufacturing

An EMS Partner Focused on Quality, Integrity & Innovation

Driven by innovation and supported by cross-functional teams, we help bring today’s most ambitious electronic products to life—from design to delivery.

About Us

Built for Scale. Backed by Infrastructure.

Certified EMS Facilities Optimized for Speed and Scale

From automated SMT lines to dedicated prototyping zones, our certified facilities across the US support agile production, tight quality control, and complex program builds.

Built for Scale. Backed by Infrastructure.

Certified EMS Facilities Optimized for Speed and Scale

From automated SMT lines to dedicated prototyping zones, our certified facilities across the US support agile production, tight quality control, and complex program builds.

Our Facilities