Table of Contents

Engineering for Mission Critical Performance

Aerospace and defense systems operate in environments where precision is not optional and failure is not acceptable. Every electronic assembly must perform flawlessly under vibration, temperature extremes, and electromagnetic stress.

At Foxtronics EMS, we understand that aerospace and defense electronics require uncompromising quality, complete documentation, and strict regulatory compliance. Our AS9100-certified processes, disciplined manufacturing controls, and engineering expertise deliver PCB assemblies that meet the most demanding standards worldwide.

The Demands of Aerospace and Defense Manufacturing

Unlike commercial products, electronics in the aerospace and defense industries must meet stringent standards for reliability, performance, and traceability. These products often support flight control systems, navigation equipment, radar, and mission-critical communications.

Foxtronics EMS builds every PCB assembly to meet or exceed the requirements of AS9100, IPC Class 3, and customer-specific defense specifications. We maintain the process discipline, documentation accuracy, and supply chain control required to ensure that each product performs dependably in the field.

AS 9100 Certified Quality System

Foxtronics EMS operates under an AS9100 certified quality management system, the global benchmark for aerospace and defense manufacturing excellence. This certification governs how we manage process control, supplier qualification, documentation, and risk management.

Key elements of our system include:

- Full traceability of materials, components, and processes

- Detailed documentation and process verification

- Supplier approval and monitoring programs

- Configuration and change control

- Corrective and preventive action tracking

These standards ensure that every product we build meets the requirements for airworthiness, reliability, and long-term performance.

Advanced Engineering and Manufacturing Capabilities

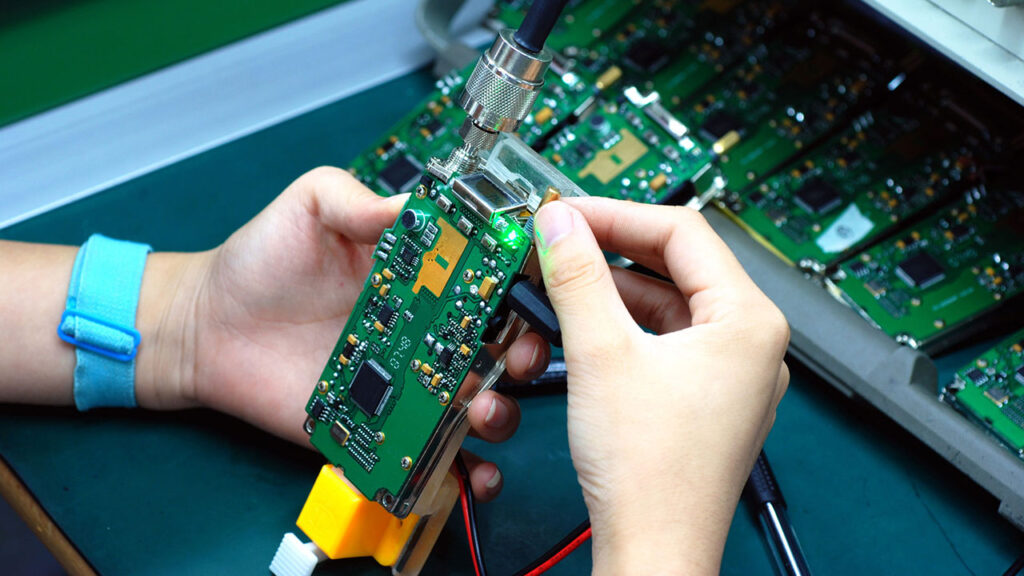

Foxtronics EMS supports both simple and highly complex aerospace and defense PCB assemblies, including multilayer printed circuit boards, mixed technology designs, and system-level integrations.

Our capabilities include:

- Surface mount and through-hole assembly

- Conformal coating and ruggedization

- Cable and harness integration

- Box build and final system assembly

- Functional and environmental testing

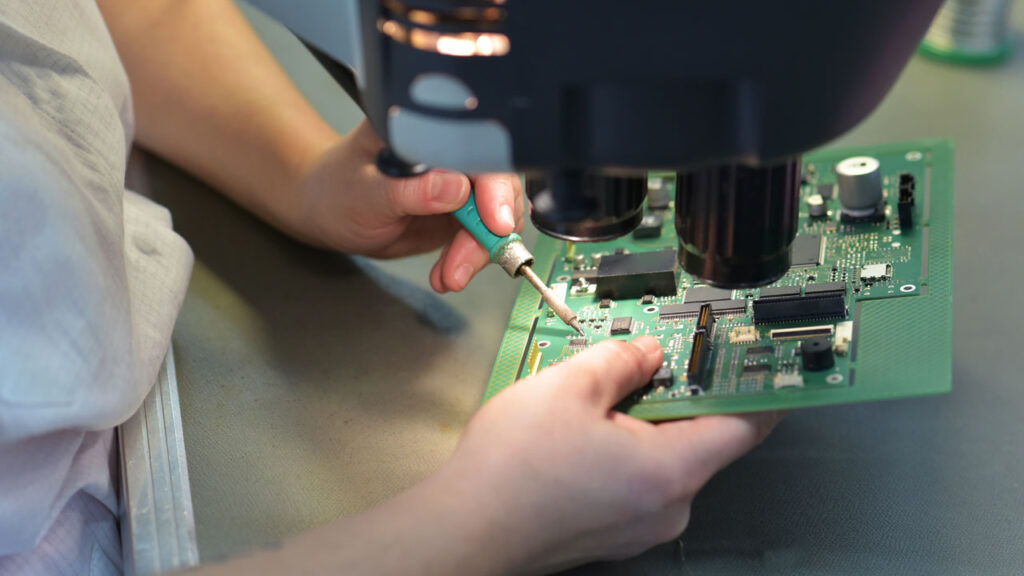

We use advanced manufacturing automation combined with skilled manual PCB assembly to ensure that every product meets the highest precision standards.

Materials Control and Supply Chain Integrity

In aerospace and defense manufacturing, supply chain management reliability is as critical as product design. Foxtronics EMS maintains controlled sourcing procedures to prevent counterfeit or non-compliant materials from entering production.

Our material management programs include:

- Supplier audits and certification verification

- Component traceability through lot and serial tracking

- Controlled storage with humidity and ESD protection

- Material inspection and validation before release to production

These controls safeguard the integrity of every assembly and maintain full transparency throughout the production process.

Testing and Qualification for Harsh Environments

Aerospace and defense electronics must endure the most demanding operating conditions imaginable. Foxtronics EMS employs a full suite of testing and integration strategies to verify performance under stress and environmental extremes.

Our testing and validation capabilities include:

- In-circuit and functional testing

- Vibration and shock simulation

- Thermal cycling and humidity exposure

- Electrical load and endurance testing

- X-ray and optical inspection for solder joint integrity

By replicating real-world conditions, we ensure that every aerospace and defense PCB assembly performs exactly as required, on the ground, in the air, or in space.

Traceability and Documentation Excellence

Traceability is essential in regulated industries like aerospace and defense. Foxtronics EMS provides full lot and serial-number tracking for every component, subassembly, and finished product.

All documentation, from incoming inspection reports to final test results, is maintained in a secure, auditable system. This complete digital record ensures accountability, supports customer audits, and provides the traceability and compliance needed to meet government and defense standards.

Collaboration and Program Support

Beyond production, Foxtronics EMS works directly with engineering teams, program managers, and procurement specialists to provide end-to-end design and engineering support. We collaborate during design reviews, qualification testing, and production transitions to ensure that each project remains on schedule and within specification.

Our team’s experience in both commercial and defense programs enables us to anticipate challenges and provide solutions that enhance manufacturability, performance, and long-term supportability.

Conclusion: Reliability Without Compromise

At Foxtronics EMS, aerospace and defense electronics are built with the same focus that defines the industries they serve, precision, reliability, and control. From rapid prototyping to full-scale production, every process, component, and test is managed to the highest standards of quality and compliance.

When performance is critical and reliability is non-negotiable, Foxtronics EMS delivers electronics built to endure the most demanding missions.

If your aerospace or defense project requires a manufacturing partner with proven quality systems and process discipline, Foxtronics EMS can help. Contact our team to learn how our AS9100-certified capabilities can support your mission-critical applications.