Table of Contents

Surface mount technology dominates most PCB assemblies today, but through hole assembly continues to play a critical role in modern electronics manufacturing. For many OEMs, through hole components are essential for mechanical strength, electrical performance, and long term reliability.

Understanding when and why through hole assembly is used helps OEMs make better design decisions and avoid manufacturing or reliability risks later in the product lifecycle.

Why Through Hole Components Are Still Used

Through hole components provide physical anchoring that surface mount components cannot always achieve. Leads passing through the PCB and soldered on the opposite side create strong mechanical bonds that are especially valuable in applications exposed to vibration, shock, or repeated mechanical stress.

Common use cases include connectors, transformers, large capacitors, inductors, relays, and power devices. In high current or high voltage designs, through hole components often offer better electrical performance and heat dissipation compared to surface mount alternatives.

For many products, a mixed technology approach that combines Surface Mount (SMT) and through hole assembly delivers the best balance of performance, reliability, and manufacturability.

Through Hole Assembly in Mixed Technology Builds

Most modern PCBs that include through hole components also include surface mount devices. This introduces sequencing and process considerations that must be addressed early.

Typically, SMT components are placed and reflowed first, followed by through hole insertion and soldering. This sequence protects temperature sensitive SMT parts and allows through hole soldering processes to be optimized independently.

Designers must account for component spacing, solder mask clearance, and hole sizing to support both assembly methods. Poor alignment between design intent and manufacturing reality can lead to solder defects, rework, or reliability concerns.

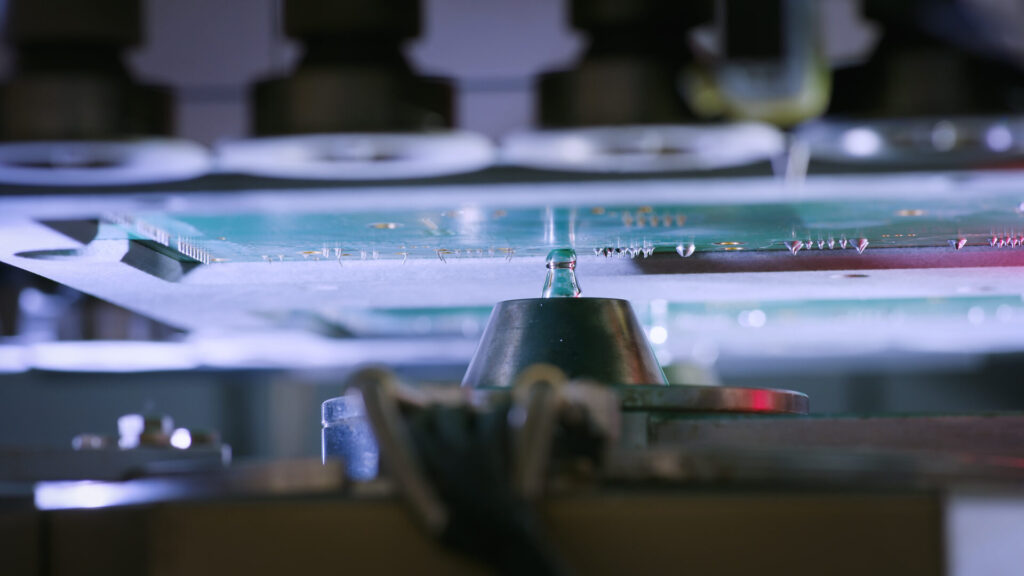

Selective Soldering vs Wave Soldering in Through Hole Assembly

Wave soldering has long been the standard for through hole assembly, but selective soldering is increasingly used for mixed technology boards.

Selective soldering allows specific joints to be soldered without exposing the entire board to molten solder. This reduces thermal stress on nearby components and improves control over solder joint quality. It is particularly valuable for dense assemblies or boards with bottom side SMT components.

Wave soldering remains effective for higher volume assemblies with simpler layouts. The choice between wave and selective soldering depends on board complexity, component mix, and production volume.

Hand Soldering Still Plays an Important Role

Despite automation advances, hand soldering remains necessary for certain through hole components and low volume or prototype builds. Connectors, mechanical hardware, rework operations, and late stage additions often require skilled manual soldering.

Consistent hand soldering quality depends on trained operators, controlled soldering equipment, proper flux selection, and adherence to industry standards. Poor hand soldering practices can introduce variability and latent defects that are difficult to detect.

Experienced EMS providers treat hand soldering as a controlled process, not an afterthought.

Inspection and Reliability Considerations

Through hole solder joints are inspected differently than surface mount joints. Proper hole fill, wetting, and fillet formation must be verified to ensure electrical and mechanical integrity.

Automated optical inspection may be supplemented with visual inspection or X ray depending on joint geometry and access. For high-reliability applications, inspection criteria are often aligned to IPC standards and customer-specific requirements. Our Testing & Integration expertise help acheive the desired quality.

Well formed through hole joints contribute significantly to long term product durability, especially in demanding environments.

Design Considerations for OEMs

OEMs can improve manufacturability and quality by considering through hole assembly requirements early in the design phase.

Key considerations include lead to hole fit, solder mask design, component spacing, and accessibility for soldering and inspection. Designs that ignore these factors often require costly adjustments during production.

Early collaboration with an EMS partner allows potential issues to be identified and resolved before release to manufacturing.

Why Through Hole Assembly Still Matters

Through hole assembly remains relevant because it solves real engineering challenges that surface mount technology alone cannot address. Mechanical strength, power handling, and durability requirements continue to drive its use across many industries.

OEMs that understand when through hole assembly is appropriate are better positioned to build reliable products without unnecessary risk.

At Foxtronics EMS, we support mixed technology assemblies that integrate SMT, through hole, and hand soldering processes into a controlled, repeatable manufacturing flow. Our focus is on helping OEMs achieve consistent quality while meeting performance and reliability goals.

Partner with Foxtronics EMS to leverage our through-hole expertise and ensure durable, reliable electronics manufacturing for your next project.