Table of Contents

Verifying PCB Assembly Performance Before It Reaches the Field

In electronics manufacturing, quality cannot be assumed; it must be proven. Testing and validation confirm that every PCB assembly performs as designed under real operating conditions. This process is essential not only for product reliability but also for safety, compliance, and customer confidence.

At Foxtronics EMS, we believe that testing is more than a checkpoint; it is an integral part of the manufacturing process. Our approach combines in-circuit testing, functional verification, and environmental stress screening to ensure that every unit leaving our facilities is production-ready and field-reliable.

The Importance of Testing in Electronics Manufacturing

Testing validates both the design and the manufacturing process. It identifies issues such as component faults, solder defects, or layout errors before the product reaches the end user. Effective testing reduces warranty costs, increases yield, and helps maintain consistent product performance.

Foxtronics EMS integrates multiple testing strategies throughout the production flow, enabling early fault detection and continuous process improvement.

In Circuit Testing (ICT)

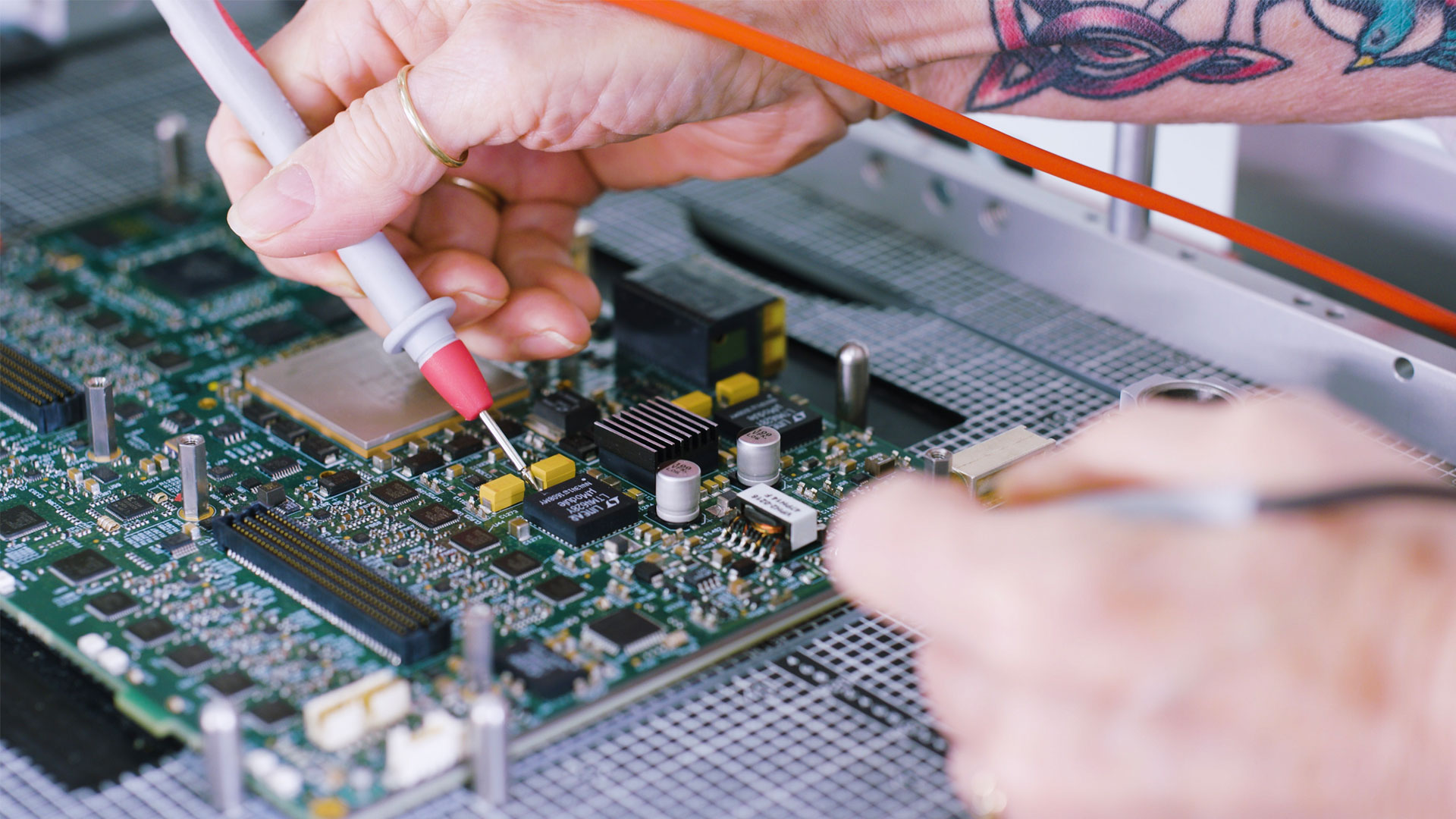

In-circuit testing verifies that individual components on a printed circuit board (PCB) are present, oriented correctly, and performing within specification. Using a bed of nails fixture or flying probe, ICT measures resistance, capacitance, voltage, and signal integrity at test points across the board.

At Foxtronics EMS, ICT provides immediate feedback to identify open circuits, shorts, or incorrect component placements. Our engineers use this data to adjust processes and improve first pass yield, ensuring that every board performs exactly as intended.

Flying Probe and Boundary Scan Testing

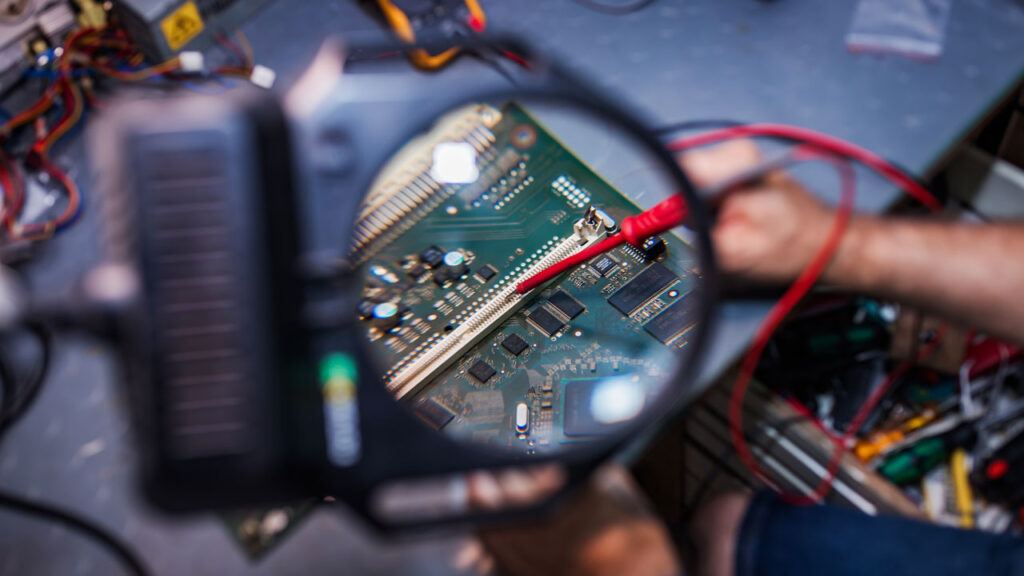

For low to medium volume or complex boards where fixturing is not practical, Foxtronics EMS employs flying probe testing. This flexible system uses precision needles that move across the board to test individual nodes without the need for a custom fixture.

Flying probe testing offers:

- Rapid setup and low tooling cost

- High coverage for small or complex assemblies

- Detection of opens, shorts, and component value errors

We also use boundary-scan (JTAG) testing for digital designs, allowing electrical verification through built-in test circuitry on the components themselves. These tools together ensure that even the most intricate PCB assemblies are verified for electrical integrity.

Functional Testing: Proving Real World Operation

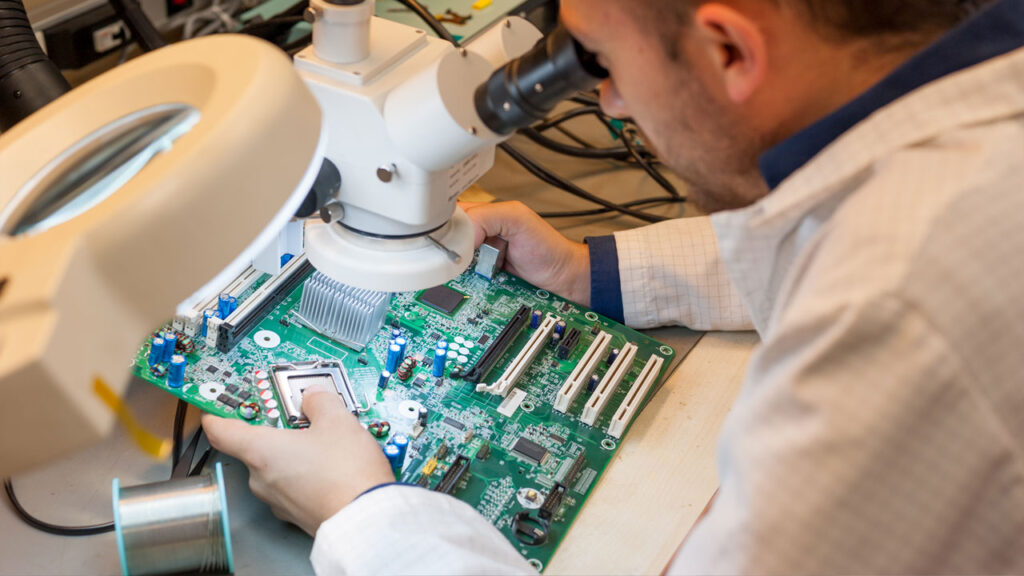

While in-circuit testing verifies that components work, functional testing confirms that the entire system performs its intended function. At Foxtronics EMS, we develop custom functional test fixtures that simulate actual operating conditions.

Functional testing may include:

- Power on and signal performance verification

- Input and output validation

- Communication and timing checks

- Firmware programming and verification

Every result is recorded in our quality database for traceability, providing a complete record of system performance before shipment.

Environmental and Stress Testing

For PCB assemblies that must perform in demanding environments, additional validation is required. Foxtronics EMS provides thermal, vibration, and humidity testing to confirm that products can withstand the conditions they will encounter in the field.

Our environmental testing capabilities include:

- Temperature cycling to evaluate solder joint fatigue

- Humidity exposure to test moisture resistance

- Vibration testing to simulate mechanical stress

- Burn-in testing for long-term reliability evaluation

These stress tests validate not just electrical performance but also mechanical durability and design integrity.

Data Collection and Traceability

Testing is only as valuable as the data it provides. Foxtronics EMS collects detailed test results for every board, linking serial numbers, lot codes, and process parameters to final test outcomes.

This digital traceability ensures that any issue can be tracked back to its source, whether in materials, process, or design. The data is analyzed for trends, allowing our quality and engineering teams to continuously refine both design and manufacturing parameters for even greater reliability.

Custom Test Development and Collaboration

Every product is unique, and so is its testing strategy. Foxtronics EMS collaborates with customers to design and build custom test fixtures and software interfaces tailored to each PCB assembly. We work with customer engineering teams to define acceptance criteria, test limits, and data collection methods.

This collaborative approach ensures that our validation process aligns perfectly with product performance goals, compliance requirements, and market expectations.

Conclusion: Proven Performance, Verified by Foxtronics EMS

Testing and validation form the foundation of manufacturing excellence. At Foxtronics EMS, we treat every test as a critical checkpoint of quality assurance and every dataset as an opportunity for improvement.

From prototype through production, our comprehensive testing and validation programs ensure that every product we deliver performs reliably, safely, and consistently, from the factory floor to the customer’s hands.

If your products demand uncompromising quality and validated performance, Foxtronics EMS can help. Contact our team to learn how our testing and functional validation services can enhance your next manufacturing program.