Table of Contents

In the world of PCB assembly manufacturing, quality cannot be inspected into a product. It must be designed, built, and validated into every stage of production. For high-reliability sectors such as Medical, Aerospace, Industrial Automation, and Automotive, field failures are more than costly, they can be catastrophic. That’s why a robust, multi-layered testing strategy is essential not only to ensure functionality but also to drastically reduce warranty costs, RMAs, and customer downtime.

Understanding the Cost of Field Failures

When a defective PCB assembly escapes to the field, the cost impact extends far beyond the replacement part. Manufacturers face:

- Direct Costs: Labor, replacement, logistics, and warranty claims.

- Indirect Costs: Brand damage, line stoppages, loss of customer trust, and potential regulatory exposure.

- Hidden Costs: Engineering resources diverted for root cause analysis, expedited logistics, and rescreening.

Studies consistently show that the cost to correct a defect increases by a factor of 10x at each successive stage, from design to production to field return. This makes early detection through layered test strategies not just best practice, but an economic imperative.

Building a Multi-Stage Test Architecture for PCB Assembly Testing

A robust testing strategy is not a single event; it’s a hierarchical process that validates design intent, verifies manufacturability, and ensures electrical integrity across the entire product lifecycle.

1. Design for Testability (DFT) and Boundary Scan

Testing begins before the first component is placed. DFT principles ensure that test points, component access, and probe spacing are optimized for downstream testing methods. Boundary-scan (JTAG/IEEE 1149.1) enables non-intrusive testing of complex digital interconnects, critical for high-density, fine-pitch designs where direct probing is limited.

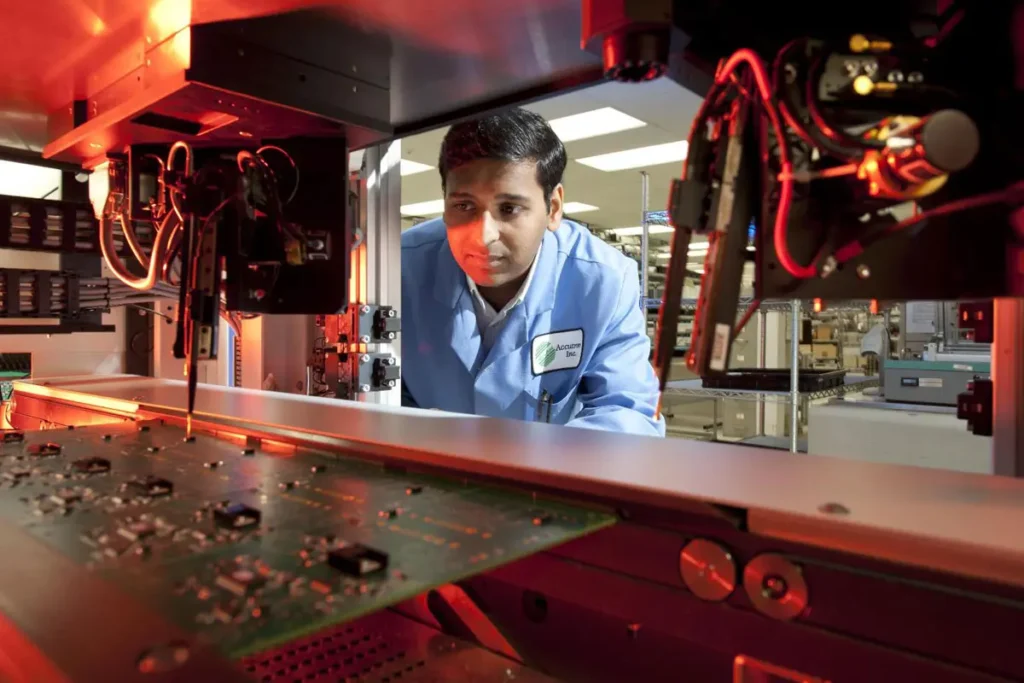

2. In-Circuit Test (ICT)

ICT provides electrical validation of each component and net on the board. It identifies opens, shorts, incorrect components, and orientation errors. Modern ICT systems at Foxtronics integrate with CAD/EDA data for automated program generation and utilize advanced vectorless test methods to detect subtle assembly issues before power-on.

3. Flying Probe Test (FPT)

For low-to-mid-volume or NPI builds, flying probe testing offers unmatched flexibility without requiring a dedicated fixture. Capable of micro-ohm resistance measurement and dynamic capacitance testing, FPT captures early-stage design or process anomalies while maintaining quick turnaround.

4. Automated Optical Inspection (AOI) and X-Ray Inspection (AXI)

AOI ensures correct placement, polarity, and solder quality at every stage: post-paste, post-placement, and post-reflow. For hidden joints such as BGAs and LGAs, 3D AXI provides volumetric solder joint analysis to detect voids, bridging, and insufficient wetting.

5. Functional and System-Level Testing

Functional testing simulates real-world operating conditions, verifying that the PCB assembly performs as designed. At Foxtronics, this often includes firmware loading, communication bus validation (CAN, LIN, RS-485, Ethernet), and parametric measurement under controlled load conditions. System-level testing further validates multi-board assemblies and integrated electromechanical systems.

Leveraging Data for Predictive Quality

The next frontier in test strategy is data integration. By linking ICT, AOI, and FPT results into a centralized Manufacturing Execution System (MES), manufacturers gain real-time visibility into defect trends, component drift, and process stability.

Machine-learning algorithms can then flag early warning indicators such as component lot deviations or stencil wear, long before a failure reaches the customer.

This data-driven feedback loop turns testing from a reactive gatekeeper into a proactive yield optimizer.

Quantifying the ROI of PCB Assembly Testing

While test fixtures, programming, and operator time add upfront cost, the return on investment is measurable. Foxtronics’ internal benchmarking shows that customers integrating full ICT + AOI + Functional Test protocols experience:

- Up to 70% reduction in field returns

- >95% first-pass yield improvement on mature product lines

- 30–50% reduction in warranty costs within 12 months of deployment

Testing, when viewed as part of the total cost of quality (TCoQ), directly impacts profitability, reliability, and customer satisfaction.

The Foxtronics Approach

Foxtronics EMS combines advanced test engineering with in-house fixture design, software validation, and complete traceability under ISO 13485 and AS9100 frameworks. Our testing infrastructure includes:

- ICT platforms

- Flying Probe Testing

- 3D AOI

- Dedicated functional test bays with custom harnessing and load simulation

- Full traceability integration with barcode serialization and test data archiving

Our philosophy is simple: We don’t guess, we test. Because every test executed in production prevents a potential field failure, every failure prevented protects your brand.

Ready to strengthen your PCB assembly process and reduce costly field failures? Foxtronics EMS offers robust testing and integration services tailored to your product needs.

Contact us today to ensure reliability from the factory floor to the field.