Table of Contents

As PCB assemblies increase in complexity, electrical continuity alone is not sufficient to ensure performance in real-world operation. While in circuit and flying probe testing verify connectivity and component-level integrity, they do not fully confirm that a board functions correctly within its intended application.

Functional testing addresses this gap by validating that assembled electronics operate as designed under defined conditions. For OEMs, understanding functional testing strategies is essential for ensuring product reliability, reducing field failures, and supporting scalable production.

What Functional Testing Verifies

Functional testing evaluates whether a PCB assembly performs according to its electrical and logical design. Unlike structural testing methods, which focus on connections and components, functional testing assesses behavior.

Typical functional tests may verify power-up sequences, voltage regulation, signal integrity, communication interfaces, firmware execution, sensor responses, and output performance. Tests are often performed under controlled input conditions that simulate real operating environments.

By exercising the board as it will be used in the field, functional testing provides confidence that the assembly meets design intent.

Why Functional Testing Is Increasingly Important

Modern electronics integrate dense digital logic, embedded processors, analog circuits, and power management on a single PCB. Interactions between these domains create failure modes that may not be detected through connectivity testing alone.

Firmware configuration, component tolerances, timing relationships, and environmental sensitivity can all influence functional behavior. As designs become more integrated, validating overall operation becomes critical to preventing latent defects from escaping into later production or customer use.

For high‑reliability sectors such as Medical, Aerospace, Industrial Automation, and Automotive, field failures are more than costly—they can be catastrophic. That’s why functional testing serves as the final safeguard, confirming that the assembled PCB performs as intended before reaching production or customer use.

Functional Test Development Considerations

Effective functional testing requires planning during the design & engineering phase. Access to test interfaces, firmware hooks, communication ports, and stimulus points must be considered early to enable repeatable testing.

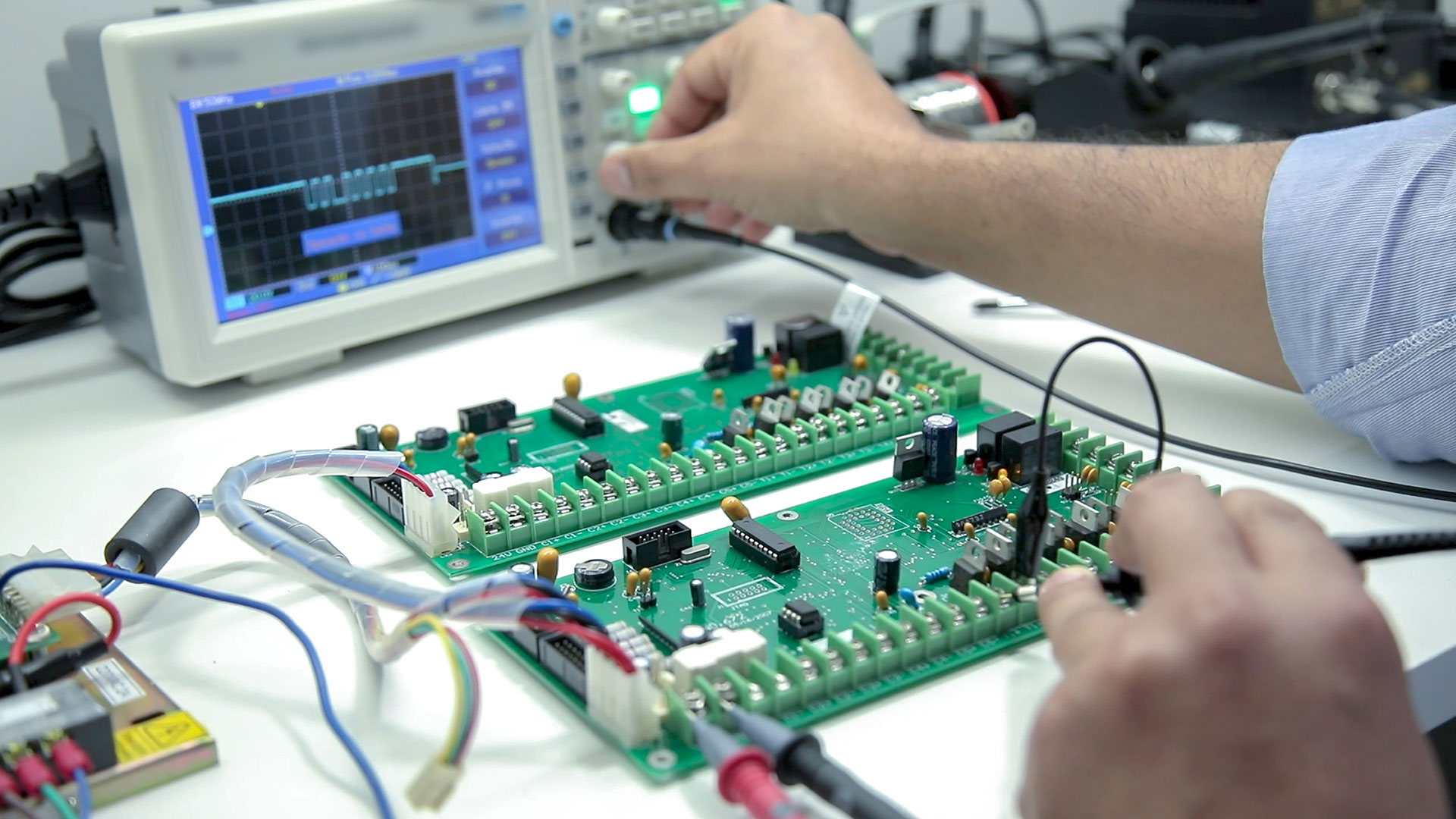

Test fixtures, harnesses, and software environments must also be developed and validated. These elements simulate the operating context while allowing measurements to be captured consistently across production units.

OEMs that design with functional testability in mind reduce development time and improve long-term test reliability.

Production vs Engineering Functional Tests

Functional testing often exists in two forms. Engineering functional tests are typically more comprehensive and used during development or validation stages. They may include extended diagnostics, detailed measurements, and stress conditions.

Production functional tests are streamlined to verify critical performance parameters efficiently within manufacturing cycle time constraints. They confirm that each unit meets defined acceptance criteria without duplicating full engineering validation.

Balancing coverage and throughput is key to scalable functional testing.

Integration With Other Test Methods

Functional testing does not replace ICT or flying probe testing. Instead, it complements them by verifying system-level operation after structural integrity has been confirmed.

A layered PCB assembly test strategy might include AOI for visual defects, ICT for connectivity, and functional testing to validate performance. Each layer addresses different failure modes, creating a comprehensive quality framework.

OEMs benefit when test methods are aligned rather than redundant.

Data Collection and Traceability

Functional test systems often capture measurement data, pass fail status, and test conditions for each unit. When linked to serial numbers, this information supports traceability and long-term reliability analysis.

Trend analysis of functional data can reveal process drift, component variability, or environmental sensitivity. This transforms functional testing from a simple gate into a source of manufacturing insight.

For regulated or mission-critical applications, documented functional results are often required for compliance.

Challenges in Functional Testing

Functional testing can be more complex to develop and maintain than structural tests. It requires hardware interfaces, software control, calibration, and ongoing validation as products evolve.

Test repeatability, fixture wear, firmware updates, and measurement accuracy must all be managed carefully. Without disciplined control, functional testing can become inconsistent or slow.

Experienced EMS providers treat functional testing as an engineered system rather than an ad hoc bench test.

What This Means for OEMs

Functional testing provides the most direct confirmation that a PCB assembly performs as intended. As electronics complexity grows, its role in manufacturing quality and reliability continues to expand.

OEMs should consider functional testing requirements early in product development and collaborate with their EMS partner to define scalable test strategies. Aligning design, firmware, and manufacturing test planning reduces risk and supports an efficient production ramp.

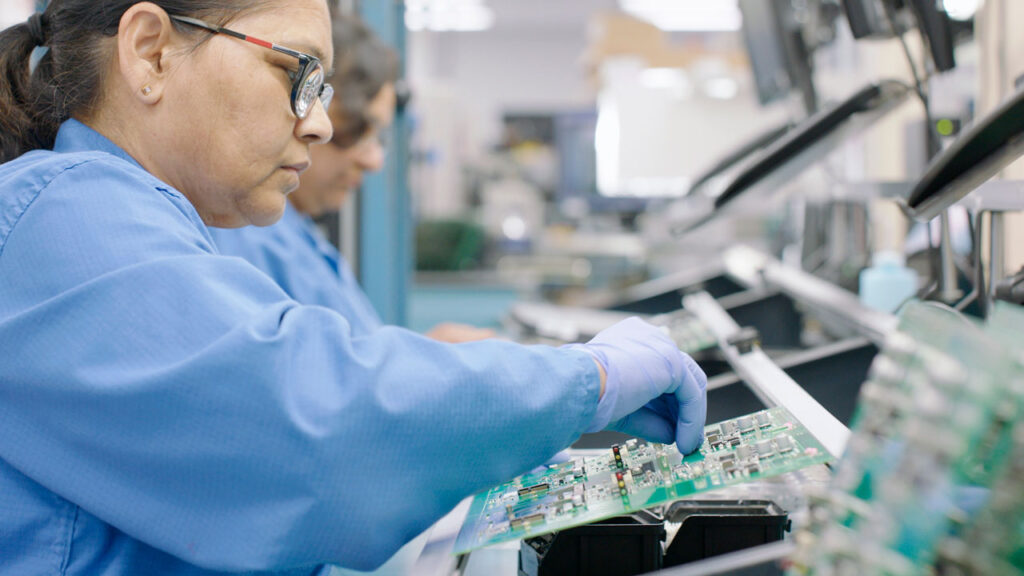

At Foxtronics EMS, functional testing is integrated into our layered inspection and test approach. By validating real-world performance in controlled production environments, we help OEMs deliver reliable electronics from prototype through sustained manufacturing.