Table of Contents

The Hidden Engine Behind Every Successful Build

A reliable electronics manufacturing partner is defined not only by technical capability but also by how effectively it manages materials, logistics, and vendor relationships. Supply chain management is the unseen backbone of every successful production run, ensuring that components arrive on time, quality standards are met, and costs remain under control.

At Foxtronics EMS, we view supply chain management as a strategic discipline that connects global sourcing with efficient factory operations. Our integrated approach keeps production flowing even in the face of shortages, volatility, or rapid design changes.

1. What Supply Chain Management Means in EMS

In electronics manufacturing, supply chain management covers every stage from component procurement to final product delivery. It includes supplier evaluation, purchasing, inventory control, logistics coordination, and risk management.

Foxtronics EMS manages this process with precision by:

- Partnering with trusted distributors and manufacturers

- Maintaining approved vendor lists for consistency and traceability

- Monitoring lead times, pricing, and availability in real time

- Coordinating material planning across multiple facilities

- Ensuring compliance with customer and regulatory requirements

This end-to-end visibility allows us to guarantee that materials flow smoothly through every step of the PCB assembly build cycle.

2. The Importance of Supplier Relationships

Strong supplier relationships are central to an efficient supply chain. At Foxtronics, we work directly with authorized component distributors and OEM partners to ensure authentic materials and consistent delivery.

This close collaboration provides:

- Early insight into potential shortages or end-of-life parts

- Access to alternate sourcing options during disruptions

- Price stability through long-term agreements

- Confidence in traceability and compliance documentation

Our suppliers are not just vendors; they are part of the Foxtronics network of reliability.

3. Managing Component Availability and Shortages

The global electronics market experiences constant fluctuation in component availability. Lead times can change overnight due to shifts in demand, logistics bottlenecks, or geopolitical events.

Foxtronics EMS proactively mitigates these risks by:

- Using real-time market intelligence to anticipate shortages

- Stocking critical components for high volume and repeat customers

- Maintaining second-source approvals for key parts

- Offering engineering support for component substitutions

By staying ahead of these challenges, we protect our customers from delays and unexpected cost increases.

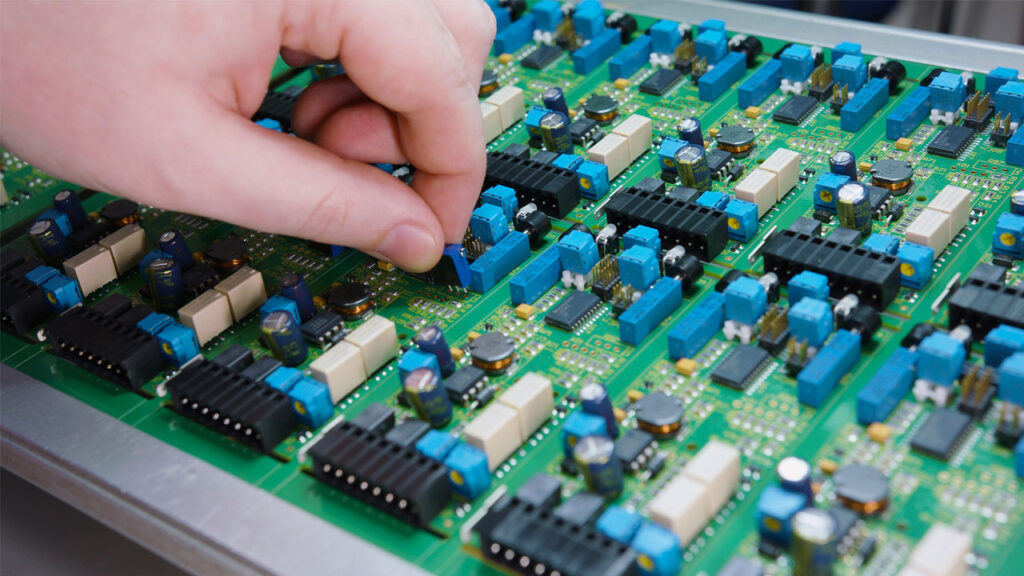

4. Inventory Management and Material Planning

An effective supply chain balances availability with efficiency. Carrying too much inventory ties up capital, while carrying too little can halt production.

Foxtronics uses advanced planning systems to manage inventory levels according to customer demand, forecasted usage, and replenishment cycles. We maintain:

- Real-time visibility into inventory across multiple locations

- Lot tracking and FIFO control for traceability

- Just-in-time delivery models for efficiency

- Safety stock programs for continuity

This precision planning minimizes waste while ensuring that materials are ready exactly when production requires them, which is especially critical for just-in-time turnkey PCB assembly projects.

5. Compliance and Quality in the Supply Chain

Every part used in an electronic assembly must meet both customer specifications and regulatory requirements. Foxtronics maintains a quality-controlled procurement system to verify that all materials conform to applicable standards.

Our supply chain programs include:

- RoHS and REACH environmental compliance

- ITAR and DFARS-controlled material handling

- Lot code and date code verification for traceability

- Certificates of conformance from every supplier

Through this disciplined approach, we guarantee that the materials behind each assembly meet the same high standards as the products we build.

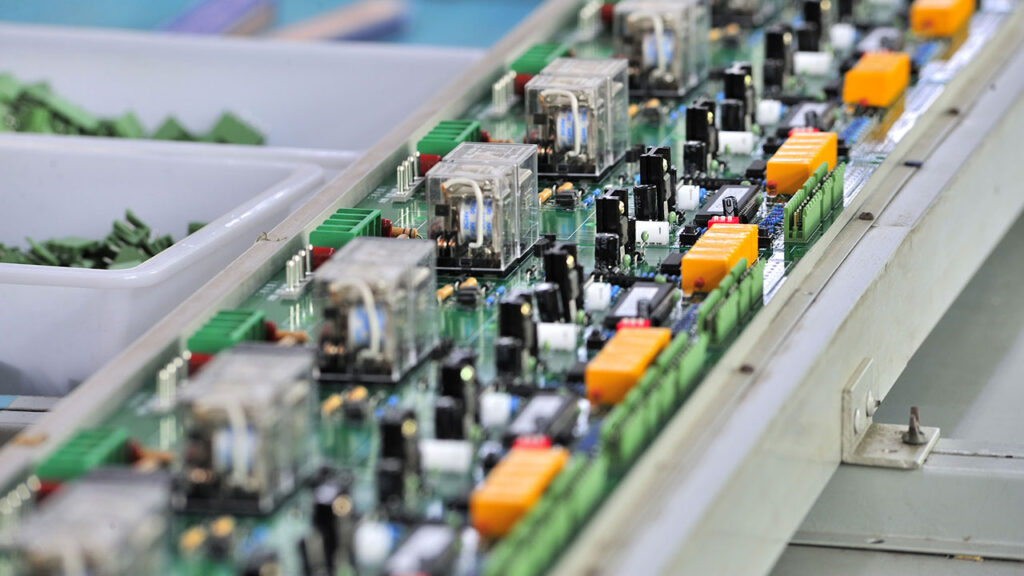

6. Logistics and Global Coordination

With customers and suppliers around the world, logistics coordination is a critical part of EMS success. Foxtronics manages both domestic and international shipments, ensuring smooth flow between suppliers, manufacturing sites, and customers.

Our logistics strategies include:

- Vendor-managed deliveries to reduce handling time

- Consolidated freight to optimize cost

- Real-time shipment tracking and reporting

- Coordination with customs and compliance agencies

These systems help maintain schedule integrity and provide customers with full visibility of their material status.

7. Risk Mitigation and Business Continuity

Supply chain disruptions can come from many directions, including component shortages, natural disasters, or unexpected geopolitical shifts. Foxtronics prepares for these scenarios through proactive risk assessment and continuity planning.

We identify critical components and alternate sources in advance, and we maintain close communication with customers to adjust procurement strategies when needed. This readiness allows us to maintain uninterrupted service even under challenging market conditions.

8. Collaboration Between Supply Chain and Engineering

Effective supply chain management is closely linked to engineering. Design decisions in PCB assembly manufacturing often influence part selection, availability, and lifecycle cost.

Foxtronics engineers work directly with our supply chain team to ensure that designs use readily available, cost-effective, and long-life components. This collaboration results in fewer redesigns, faster production ramps, and improved long-term reliability.

Conclusion: A Stable Supply Chain Drives Manufacturing Success

At Foxtronics EMS, supply chain management is not a back-office function; it is a strategic pillar of our success. From sourcing and logistics to compliance and continuity, every element is managed with precision and transparency.

We understand that our customers rely on us not only for technical expertise, but also for supply stability. By combining smart planning, strong partnerships, and real-time visibility, we deliver consistency and confidence in every PCB assembly and electronic product we build.

If your organization needs a manufacturing partner with proven supply chain strength, Foxtronics EMS can help. Contact our team to learn how our strategic sourcing and material management systems ensure stability and success in every build.