Table of Contents

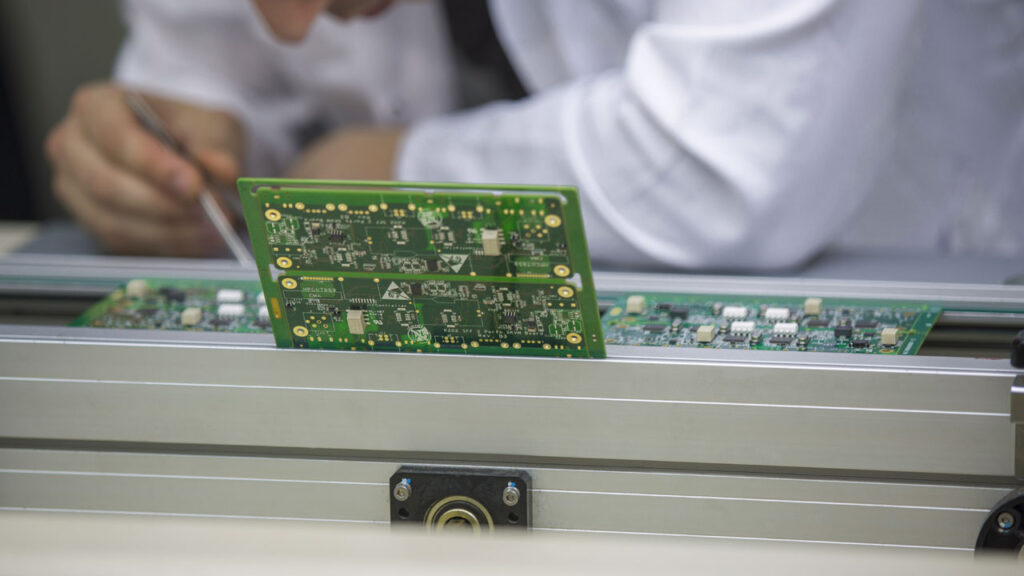

The Backbone of Reliable PCB Assembly Manufacturing

In electronics manufacturing, success is built on more than PCB assembly precision. It begins long before a circuit board reaches the production line; it starts with the supply chain.

At Foxtronics EMS, we understand that component availability, lead times, and sourcing strategy directly affect delivery schedules, costs, and product reliability. Our supply chain management process ensures that every part, material, and vendor contributes to consistent, dependable production.

The Importance of Supply Chain Management

A well-managed supply chain is essential for PCB assembly manufacturing because every electronic product depends on hundreds or even thousands of components. Any disruption, from a global shortage to a delayed shipment, can impact production timelines and customer satisfaction.

Foxtronics EMS addresses these challenges through proactive planning, supplier partnerships, and data-driven forecasting. By maintaining visibility and control from procurement to production, we minimize risk and ensure business continuity for our customers.

Strategic Sourcing and Vendor Qualification

The quality of any PCB assembly begins with the quality of its components. Foxtronics EMS works only with verified suppliers that meet our standards for quality, traceability, and reliability.

Our sourcing process includes:

- Approved vendor lists based on performance history

- Supplier audits and quality evaluations

- Certificates of conformance and material verification

- Continuous supplier monitoring and improvement programs

This structured approach ensures that every material entering our facilities meets the specifications required for consistent performance and compliance.

Mitigating Risk in a Dynamic Global Market

Global component markets can be unpredictable, with sudden shortages, allocation events, and pricing fluctuations. Foxtronics EMS actively manages risk by monitoring market conditions and developing flexible sourcing strategies for critical parts.

Our team uses multiple tactics to reduce exposure, including:

- Alternate part qualification and cross-referencing

- Early visibility into demand and lifecycle changes

- Buffer inventory and scheduled order releases

- Strategic supplier diversification

Through proactive planning, we help customers maintain stable production even during volatile supply conditions.

Traceability and Compliance

Traceability is not optional in modern electronics manufacturing; it is a core part of quality assurance. Foxtronics EMS maintains full traceability for every component, linking part numbers, lot codes, and supplier data to each assembly we build.

This documentation ensures compliance with industry standards such as ISO 9001, AS 9100, and ISO 13485, while supporting rapid response to any potential field or quality concern. Our customers can rely on complete transparency from incoming inspection to final product shipment.

Managing Obsolescence and Lifecycle Transitions

Component obsolescence is one of the greatest challenges in electronics manufacturing. As technologies evolve, older parts are discontinued, forcing redesigns or substitutions that can affect production schedules.

Foxtronics EMS helps customers plan for these transitions by:

- Monitoring part lifecycles and end-of-life notifications

- Identifying alternate sources early in the design phase

- Recommending compatible replacements

- Coordinating with engineering teams for qualification and validation

By addressing obsolescence before it disrupts production, we protect our customers from costly downtime and redesign delays.

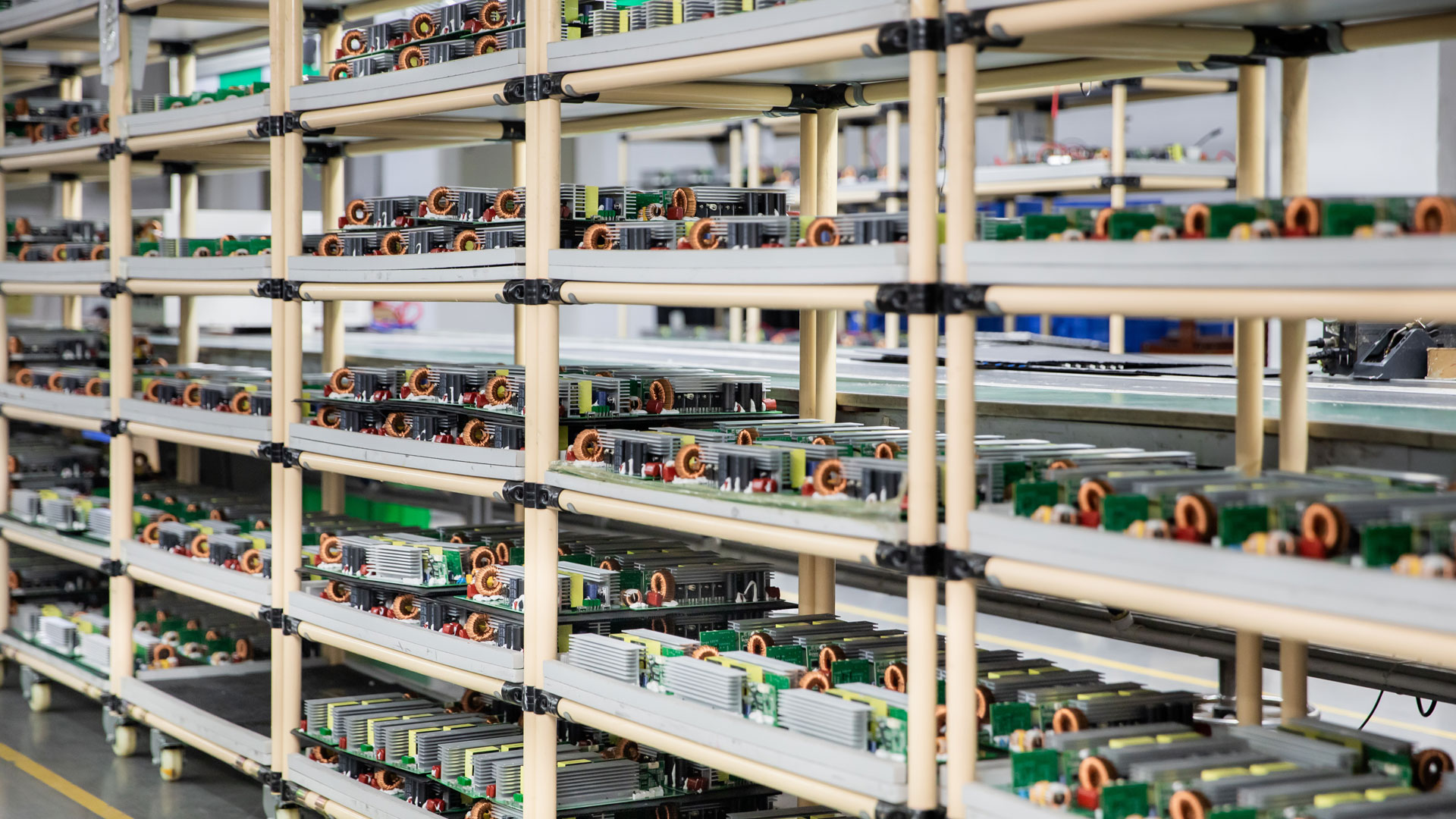

Inventory Management and Material Control

Managing inventory efficiently helps balance cost and availability. Foxtronics EMS uses a combination of just-in-time replenishment and strategic stocking to maintain optimal material flow.

Our inventory management systems track:

- Real-time stock levels and reorder points

- Lot codes and date codes for traceability

- Shelf life monitoring for sensitive components

- FIFO and moisture control procedures for storage integrity

These controls ensure that every assembly is built with fresh, verified, and compliant materials.

Collaboration and Forecasting with Customers

Supply chain success depends on communication and collaboration. Foxtronics EMS works closely with customers to forecast demand, plan material purchases, and align production with delivery schedules.

We integrate our systems with customer forecasts and MRP data to identify potential shortages before they occur. This partnership approach enables our customers to respond faster to market changes and maintain consistent production output.

Conclusion: Dependable Manufacturing Begins with Dependable Supply Chains

At Foxtronics EMS, we view supply chain management as a strategic advantage, not an administrative task. Our sourcing, traceability, and planning systems ensure that every part and process contributes to reliable production performance.

By combining proactive procurement, transparent communication, and disciplined process control, we deliver the confidence our customers need to meet demand without compromise.

If your manufacturing program requires a stable supply, cost control, and trusted sourcing, Foxtronics EMS can help.

Contact our team to learn how our turnkey project management and integrated supply chain management systems support consistent, on-time production.