Table of Contents

The Invisible Threat to Electronics

Electrostatic discharge, or ESD, is one of the most common yet underestimated causes of damage in electronic assemblies. Even a static event as small as one hundred volts, far below human perception, can permanently weaken sensitive semiconductor devices. Over time, this can lead to product failure, degraded performance, or costly warranty returns.

At Foxtronics EMS, ESD control is built into every stage of our production process. From materials handling to final packaging, our focus is on creating an electrostatically safe environment that protects your PCB assemblies and ensures long-term reliability.

Understanding the Impact of ESD

Every time two materials make and break contact, a static charge can form. In printed circuit board assembly, these charges can build up through routine actions such as peeling tape, handling plastic trays, or walking across a floor. Without proper grounding and control measures, that charge can discharge through a component and destroy internal circuitry.

The effects of ESD fall into two categories

Catastrophic Failure: The component is immediately rendered nonfunctional.

Latent Failure: The component appears functional but has sustained hidden damage that leads to failure later in the field.

Both outcomes are unacceptable in high-reliability applications such as medical, aerospace, and industrial systems, key markets Foxtronics serves every day.

The Foundation of an ESD Safe Environment

Effective ESD control starts with a comprehensive system that integrates materials, personnel, and processes. Key elements include:

- ESD Flooring and Work Surfaces: Static dissipative mats and floors prevent charge accumulation and allow safe discharge to ground.

- Grounding Systems: Every workstation, tool, and operator is grounded to maintain a common reference potential.

- Ionization: Air ionizers neutralize static charges on insulators or isolated conductors that cannot be directly grounded.

- Humidity Control: Proper environmental conditioning reduces the likelihood of static buildup in dry conditions.

At Foxtronics EMS, each production cell is continuously monitored to verify that grounding resistance and environmental factors remain within strict ESD control standards.

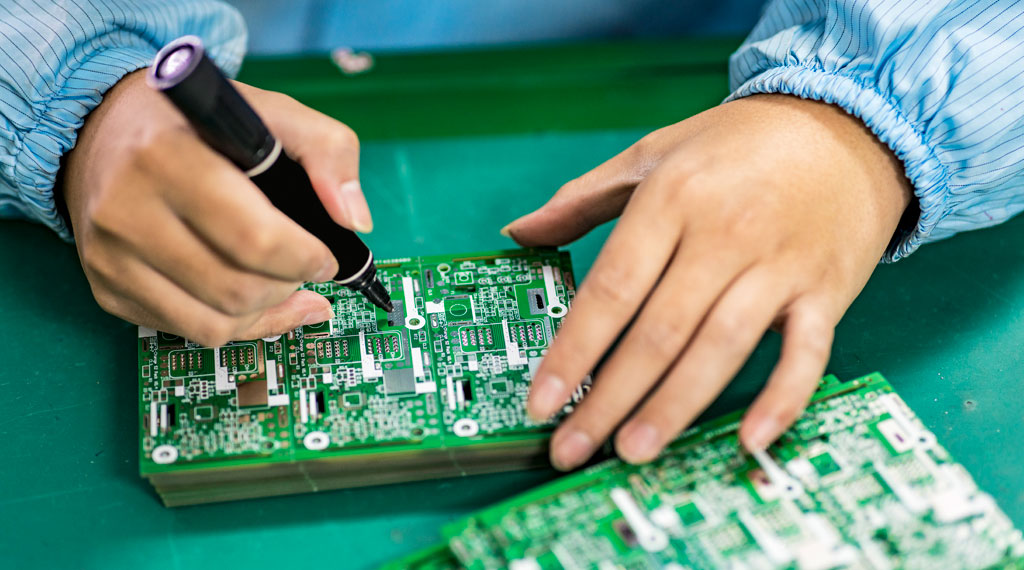

Personnel Training and Compliance

People are often the largest source of static electricity in a PCB assembly area. That is why Foxtronics EMS emphasizes training and discipline. All operators, engineers, and visitors are required to wear ESD safe garments, wrist straps, and footwear while in controlled areas.

Regular audits ensure compliance with ANSI ESD S2020 and IPC A610 Class 3 workmanship standards. Our internal ESD coordinators verify grounding points, wrist strap resistance, and material certifications at scheduled intervals.

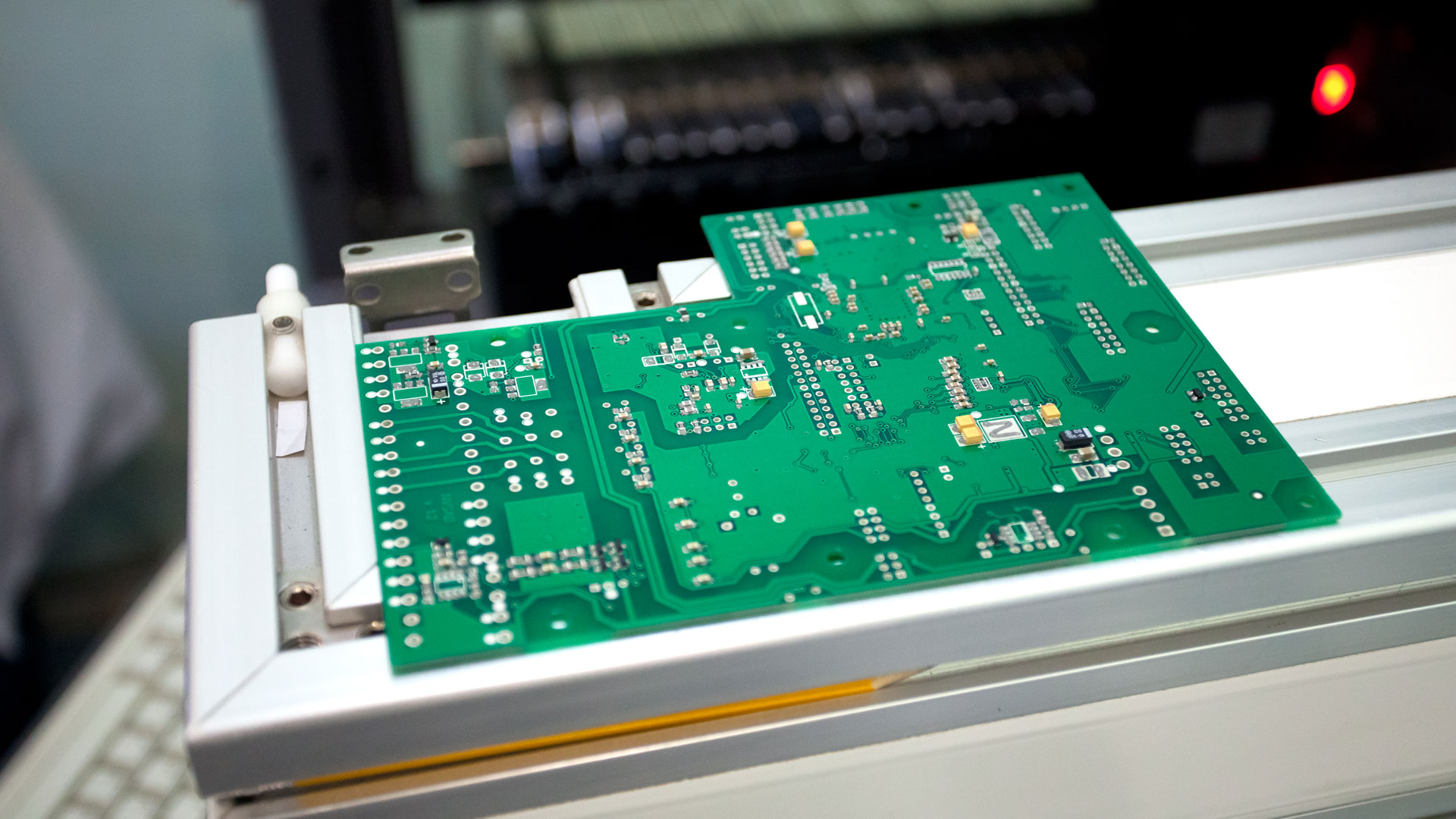

Material Handling and Packaging

ESD protection does not end once a PCB board leaves the workbench. Sensitive PCB assemblies must remain shielded throughout transport and storage.

Foxtronics EMS uses conductive trays, ESD shielding bags, and moisture barrier packaging to ensure full protection from PCB assembly through final delivery. Each package is labeled with ESD warnings and traceability data for easy verification during receiving and inspection.

Continuous Verification and Testing

To maintain consistency, our production teams regularly test grounding integrity, surface resistance, and ionizer balance using calibrated instruments. These measurements are logged as part of our process traceability records, giving customers confidence that ESD protection is not an assumption but a proven control system.

Conclusion: Reliability Starts with Control

ESD is silent, invisible, and often overlooked, but its impact can be devastating. Effective ESD protection in PCB assembly requires attention to every detail: the environment, equipment, materials, and people.

At Foxtronics EMS, we understand that reliability begins long before the first component is soldered. Through disciplined ESD control, continuous monitoring, and adherence to global standards, we safeguard your electronics from the inside out.

Interested in learning more about our ESD control and quality testing systems?

Contact our engineering team for a facility tour.