Table of Contents

Printed Circuit Board Assemblies (PCBAs) are the foundation of nearly every electronic product on the market today. The way components are mounted and secured to the board can make all the difference in performance, cost, and reliability. Two primary methods dominate the industry: Surface Mount Technology (SMT) and Through-Hole Assembly (THA). Understanding the strengths and trade-offs of each is key to making the right choice for your design.

What is SMT Assembly?

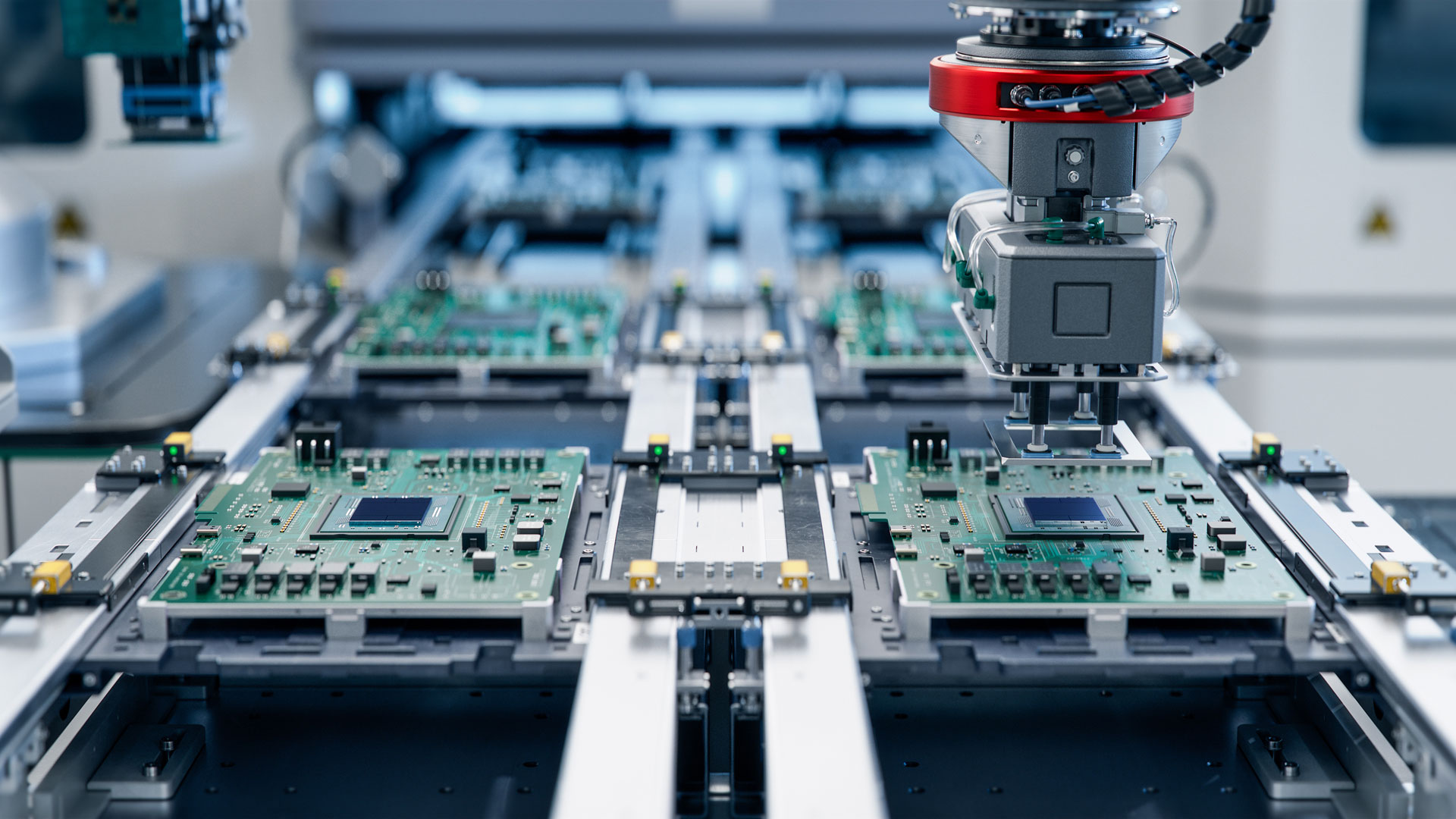

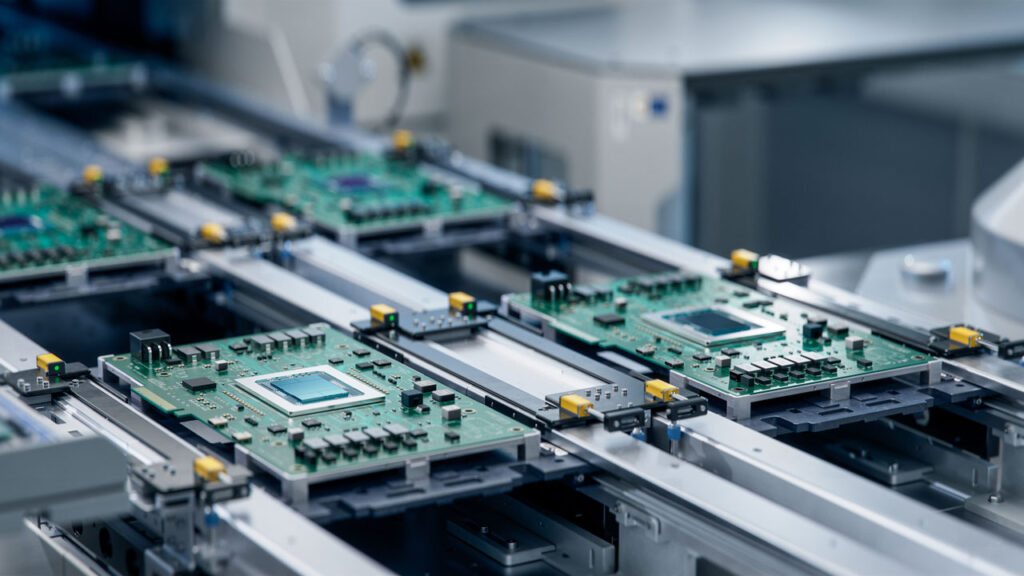

Surface Mount Technology places components directly onto the surface of the PCB using automated pick-and-place machines. These components, called SMDs (Surface Mount Devices), are soldered using reflow ovens to ensure precision and consistency.

SMT has become the backbone of modern electronics manufacturing because it enables manufacturers to build smaller, lighter, and faster assemblies without sacrificing performance.

Advantages of SMT

• Miniaturization Ideal for compact, high-density designs where space is at a premium.

• High Speed & Volume Automated lines allow for faster production runs and scalable throughput.

• Cost-Effective Streamlined assembly time, lower overall manufacturing costs.

• Performance Shorter lead paths improve signal integrity and electrical performance.

Best for applications where space, speed, and performance are critical.

What is Through-Hole Assembly?

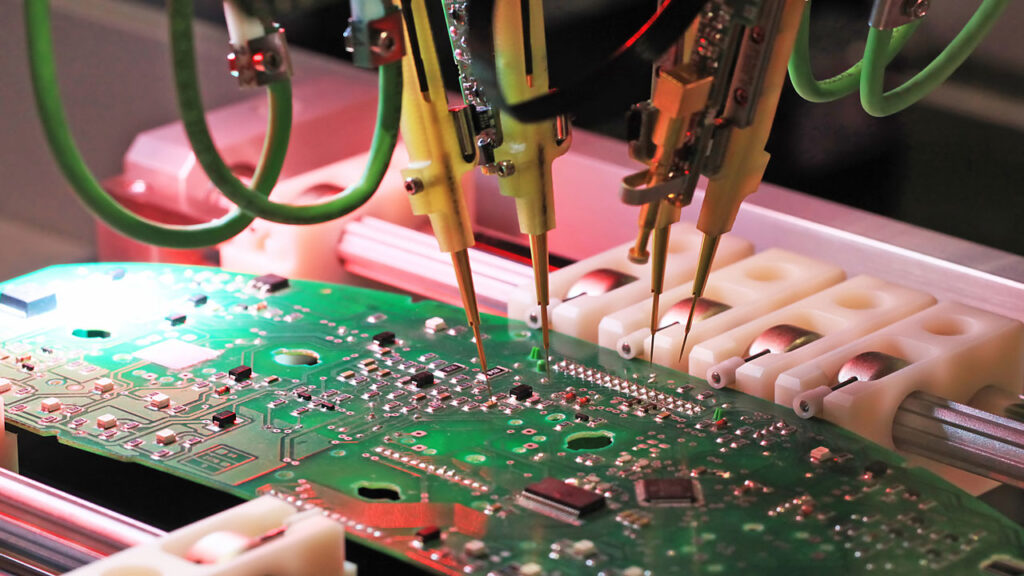

Through-Hole Assembly is the traditional method where component leads are inserted into drilled holes on the PCB and soldered either manually or by wave soldering. While SMT dominates most consumer and industrial products today, through-hole still plays a vital role in certain applications.

When reliability under stress matters more than size, Through-Hole remains unmatched.

Advantages of Through-Hole

• Durability Leads that pass through the board create stronger mechanical bonds.

• High Reliability Well-suited for mission-critical or high-stress environments.

• Ease of Prototyping Larger components are easier to handle during early builds or testing.

Best for industries where vibration resistance, ruggedness, and heat tolerance are essential.

SMT vs. Through-Hole: Making the Choice

The decision isn’t always “either/or.” Many modern assemblies use mixed technology, combining SMT for miniaturization and performance with through-hole for connectors, switches, or larger components that require mechanical strength.

Key considerations when choosing your process:

• Product Environment Harsh conditions may favor through-hole for reliability.

• Size & Weight Portable or space-constrained devices benefit from SMT.

• Production Volume High-volume runs are more efficient with SMT.

• Budget & Timeline SMT typically lowers overall costs, but through-hole can simplify prototypes.

How Foxtronics EMS Helps You Decide

At Foxtronics EMS, we offer end-to-end PCB assembly services across our U.S.-based facilities, supporting SMT, through-hole, and mixed-technology builds. Whether you need rapid prototyping, low-volume high-mix production, or full-scale manufacturing, our in-house DFM expertise and engineering team ensure your design is optimized for performance, compliance, and cost efficiency.

Every assembly is backed by:

• IPC-certified workmanship

• Advanced inspection systems (AOI, X-ray for leadless devices, flying probe, ICT, functional testing)

• Full traceability across the supply chain and production

The Bottom Line

Choosing between SMT and Through-Hole isn’t just a technical decision; it’s a strategic one. The right process balances performance, reliability, and cost while supporting your product’s long-term success.

Whether you’re developing next-gen medical devices, rugged industrial controllers, or aerospace systems, Foxtronics EMS has the expertise to guide you to the right assembly method—and deliver with confidence.

Partner with Foxtronics EMS to bring your PCB designs to life. Contact us today!