Table of Contents

How to Evaluate Capabilities, Quality Systems, Scalability, and Cultural Fit

Selecting the right Electronics Manufacturing Services (EMS) partner is one of the most critical decisions an OEM can make. Your choice affects time-to-market, product reliability, long-term costs, and customer satisfaction. With so many PCB assembly contract manufacturers claiming expertise, it is essential to separate marketing promises from measurable capability.

Here are four dimensions every OEM should evaluate when qualifying an EMS partner, along with key questions that reveal their true strengths.

1. Capabilities and Technology Depth

Why it matters:

Your product’s complexity determines the technical requirements your EMS provider must meet. An EMS partner’s in-house capabilities determine not only whether they can build your design but also whether they can improve it.

Questions to ask:

- Do you offer both Surface-mount (SMT) and through-hole assembly in the same facility?

- What is your process for DFM (Design for Manufacturability) and DFT (Design for Test) feedback?

- Can you manage cable harnessing, injection molding, conformal coating, or full box build integration internally?

What to look for:

An experienced EMS provider should demonstrate broad vertical integration from PCB assembly to system integration, supported by automation, testing services, and engineering expertise.

2. Quality Systems and Certifications

Why it matters:

Quality is not just an outcome but a discipline embedded in every process. Certifications are a starting point, but how they are applied day to day is what separates good suppliers from great ones.

Questions to ask:

- Are you certified to ISO 9001, ISO 13485 (medical), AS9100 (aerospace), or ITAR (defense)?

- How do you ensure traceability across materials, components, and assemblies?

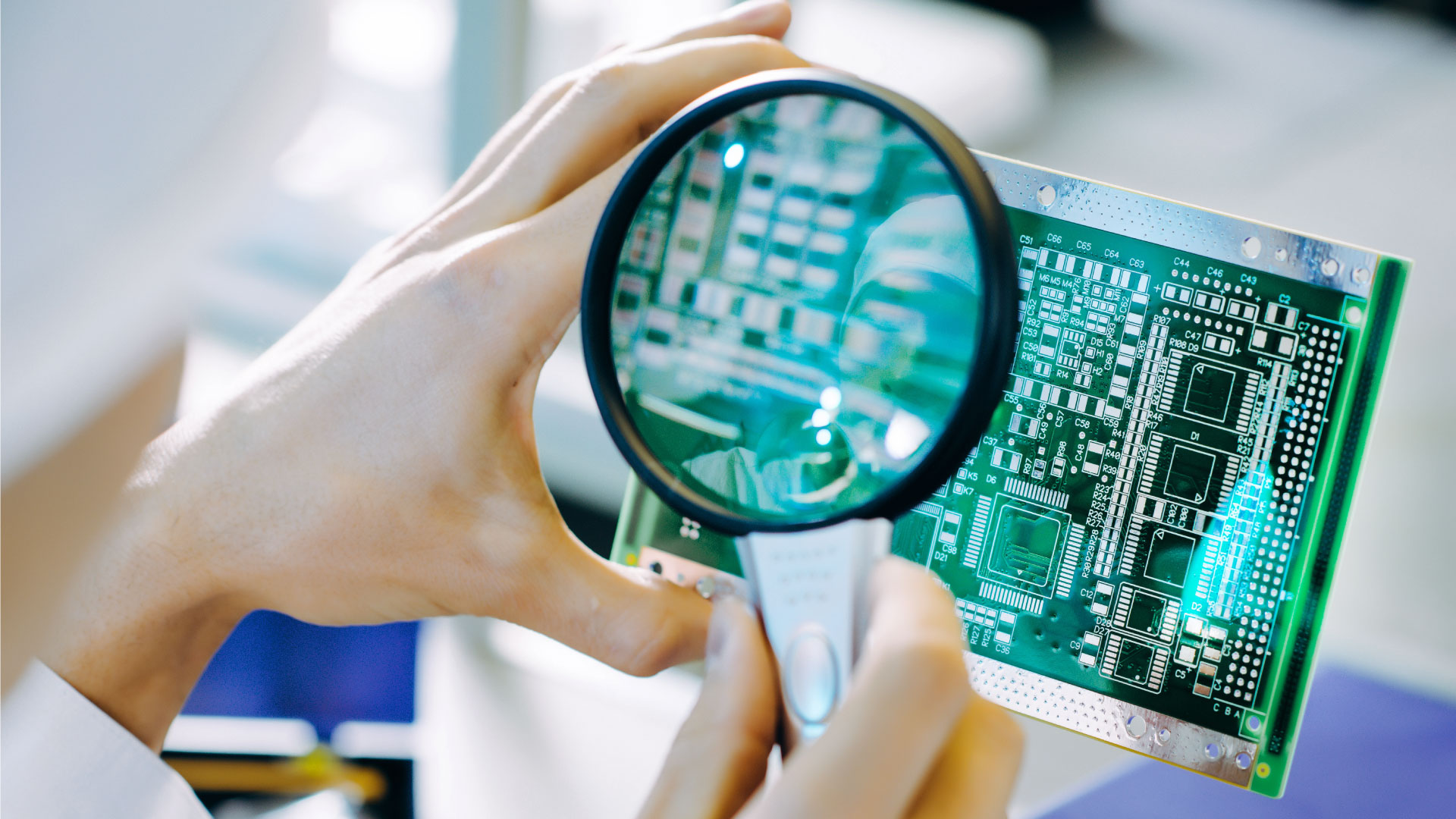

- What testing capabilities do you have such as ICT, AOI, X-ray, flying probe, and functional testing?

- Can you provide process control data and yield reporting upon request?

What to look for:

A strong quality management system backed by proactive testing and complete traceability, not just compliance paperwork.

3. Scalability and Supply Chain Strength

Why it matters:

Your EMS partner should be able to grow with you. Whether it is prototype, NPI, or complete PCB assembly production services, their flexibility determines your ability to respond to market changes.

Questions to ask:

- How do you scale from prototype to production?

- What is your global sourcing strategy and supplier qualification process?

- How do you mitigate component shortages and obsolescence risks?

- Can you support regional manufacturing to reduce lead times or tariffs?

What to look for:

Partners that demonstrate supply chain agility, data-driven planning, and the ability to adapt during global disruptions.

4. Cultural and Strategic Fit

Why it matters:

Beyond technical capability, success depends on communication, transparency, and shared values. The best EMS relationships feel like extensions of your own team.

Questions to ask:

- How often do engineering and project management teams communicate with customers?

- How do you handle change orders and design revisions?

- What tools do you use for real-time visibility into builds and material status?

- Can you provide examples of long-term customer partnerships and growth stories?

What to look for:

A partner that values collaboration, communicates proactively, and aligns with your pace and priorities.

Final Thought

Selecting an Electronics Manufacturing Services (EMS) provider is not about finding the lowest quote. It is about identifying a partner who can deliver consistency, quality, and support as your products evolve. The right EMS relationship accelerates innovation and protects your brand reputation.

Foxtronics EMS is that partner, combining advanced assembly, testing, and system-level manufacturing with the responsiveness and transparency that OEMs depend on.

One Partner. Infinite Possibilities.

Partner with Foxtronics EMS and power your next innovation with confidence. Contact us today!