Table of Contents

As PCB assemblies become denser and more complex, inspection plays a critical role in maintaining quality and controlling cost. Automated optical inspection, commonly referred to as AOI, has become a foundational tool in modern PCB assembly by enabling early defect detection and supporting process stability.

For OEMs, understanding how AOI is used in electronics manufacturing helps clarify its value beyond simple pass fail inspection. When applied correctly, AOI improves yield, reduces rework, and strengthens overall manufacturing discipline.

What AOI Does in the SMT Assembly Process

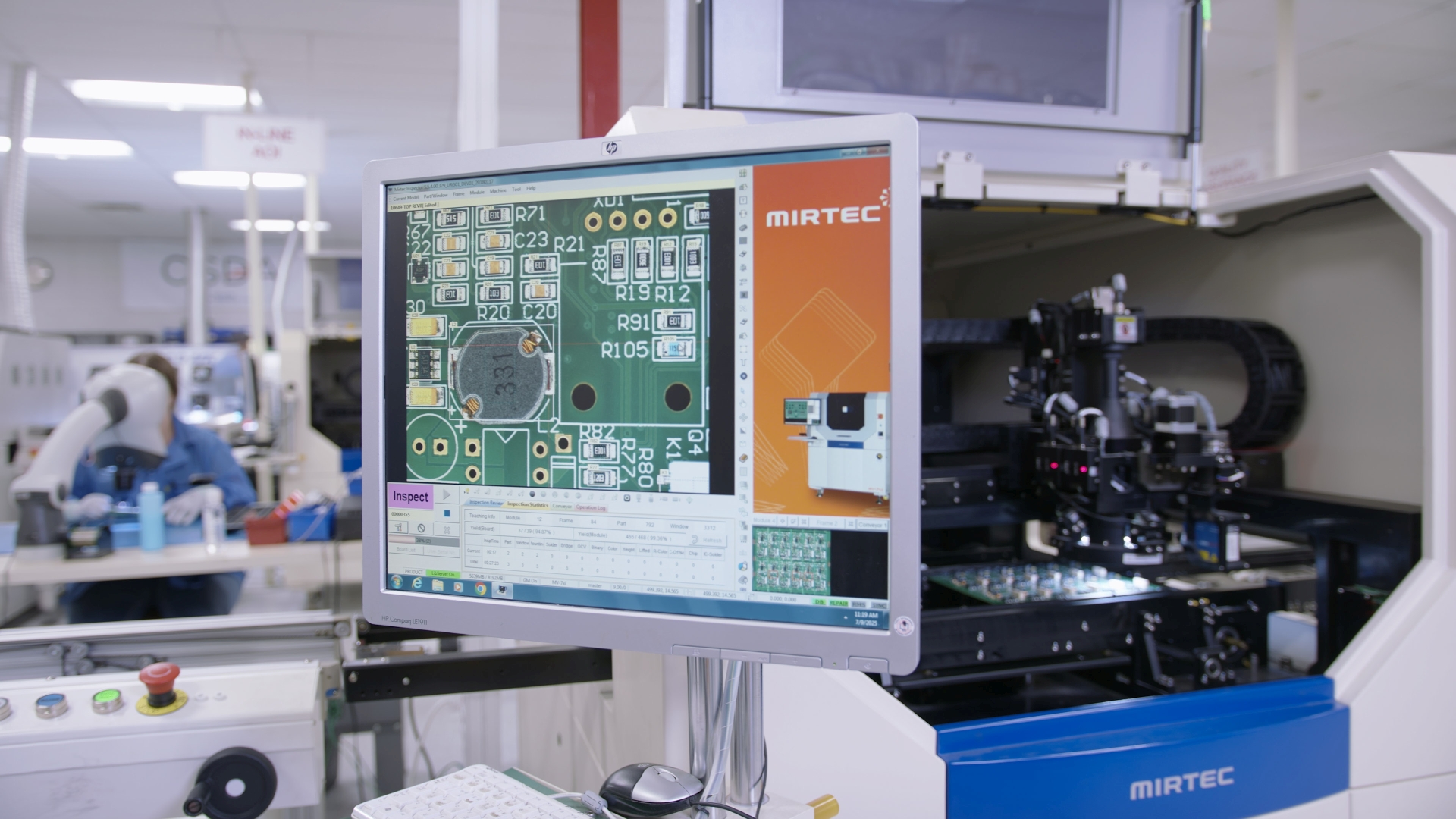

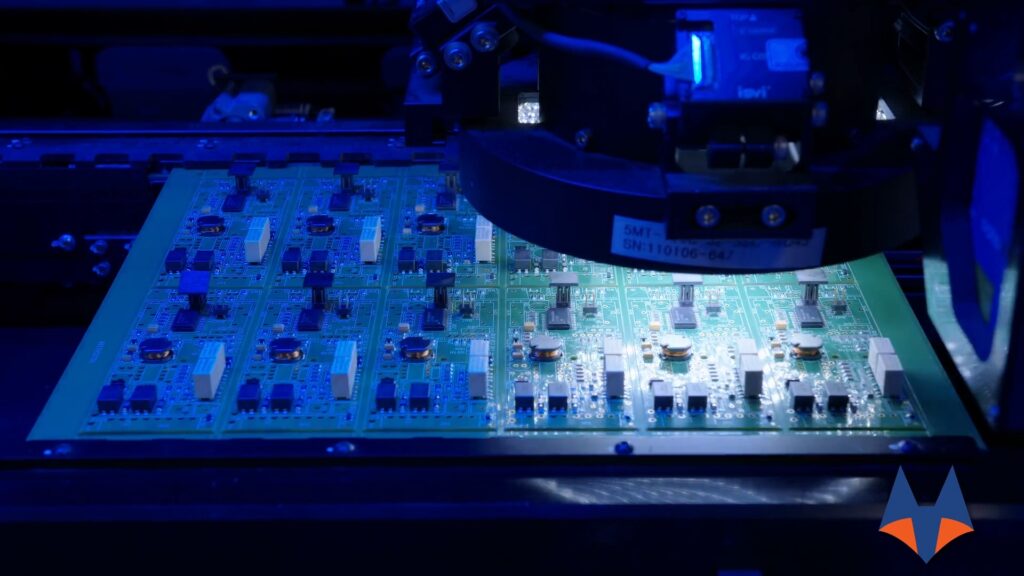

AOI systems use high-resolution cameras, lighting, and software algorithms to inspect PCB assemblies for defects. These systems compare the assembled board to known good data and identify deviations such as missing components, misalignment, polarity errors, solder defects, and workmanship issues.

AOI is typically deployed at multiple points in the PCB assembly process. Post placement AOI verifies component presence and orientation before soldering. Post reflow AOI evaluates solder joint formation and final placement accuracy.

By inspecting early and often, manufacturers can prevent defects from moving downstream where they become more expensive to correct.

Why Early Defect Detection Matters

The cost of a defect increases significantly the further it travels through the manufacturing process. A misplaced component caught immediately after placement can often be corrected quickly. The same defect found after functional test or final assembly may require extensive rework or scrapping of the board.

AOI allows manufacturers to identify issues close to their source. This reduces rework time, protects schedule commitments, and improves overall yield. For OEMs, this translates into more predictable production outcomes and lower total cost.

Automated Optical Inspection (AOI) as a Process Control Tool

One of the most valuable aspects of AOI is its role in process control rather than defect sorting. AOI data can reveal trends that indicate upstream issues such as solder paste volume variation, placement drift, or stencil wear.

When inspection results are analyzed over time, manufacturers can make targeted adjustments to printing, placement, or reflow processes before defect rates increase. This proactive approach supports continuous improvement and process stability.

OEMs benefit when their EMS partner uses AOI data as part of an active quality management system rather than treating inspection as an isolated step.

Common Defects Detected by AOI

AOI is particularly effective at detecting visual and geometric defects. These include missing components, incorrect orientation, tombstoning, solder bridging, insufficient solder, and lifted leads.

While AOI cannot detect every possible failure mode, it provides broad coverage for many of the most common assembly defects. When combined with other inspection and test methods, AOI forms a critical layer in a robust quality strategy.

Understanding AOI’s strengths and limitations helps OEMs align inspection coverage with product risk and application requirements.

Programming and False Call Management

Effective AOI inspection depends heavily on proper programming. Overly aggressive settings can result in excessive false calls that slow production and reduce confidence in inspection results. Insufficient sensitivity can allow real defects to escape.

Optimized AOI programs balance sensitivity and specificity. This requires experienced engineering support, validated golden boards, and ongoing tuning as designs or processes change.

Well managed EMS providers treat AOI programming as an engineering function, not a one time setup task.

AOI in High Reliability and Regulated Applications

In high-reliability industries, AOI supports traceability, documentation, and compliance requirements. Inspection records provide objective evidence that assemblies meet defined workmanship criteria.

AOI data can be linked to serial numbers, enabling detailed product history and supporting root cause analysis if issues arise in the field. This level of visibility is increasingly expected by OEMs operating in regulated or mission-critical environments.

How AOI Fits Into a Broader Quality Strategy

AOI is most effective when integrated into a layered quality approach. It complements solder paste inspection, in circuit testing, functional testing, and visual inspection rather than replacing them.

Each inspection and test method addresses different failure modes. Together, they create a comprehensive system that improves confidence in product quality and reliability.

OEMs should work with their EMS partner to define inspection strategies that balance coverage, cost, and production volume.

What Automated Optical Inspection (AOI) Means for OEMs

AOI has evolved from a simple inspection checkpoint into a critical process control and quality assurance tool. OEMs that understand its role can make more informed decisions about inspection coverage and manufacturing readiness.

When applied correctly, AOI improves yield, reduces rework, and strengthens manufacturing discipline across the PCB assembly process.

At Foxtronics EMS, AOI is integrated into our SMT assembly workflows to support early defect detection and continuous improvement. By combining advanced inspection systems with disciplined process control, we help OEMs achieve consistent quality from prototype through production.

Partner with Foxtronics EMS to leverage advanced AOI inspection and disciplined process control, ensuring higher yields, fewer defects, and consistent PCB Assembly quality.