Table of Contents

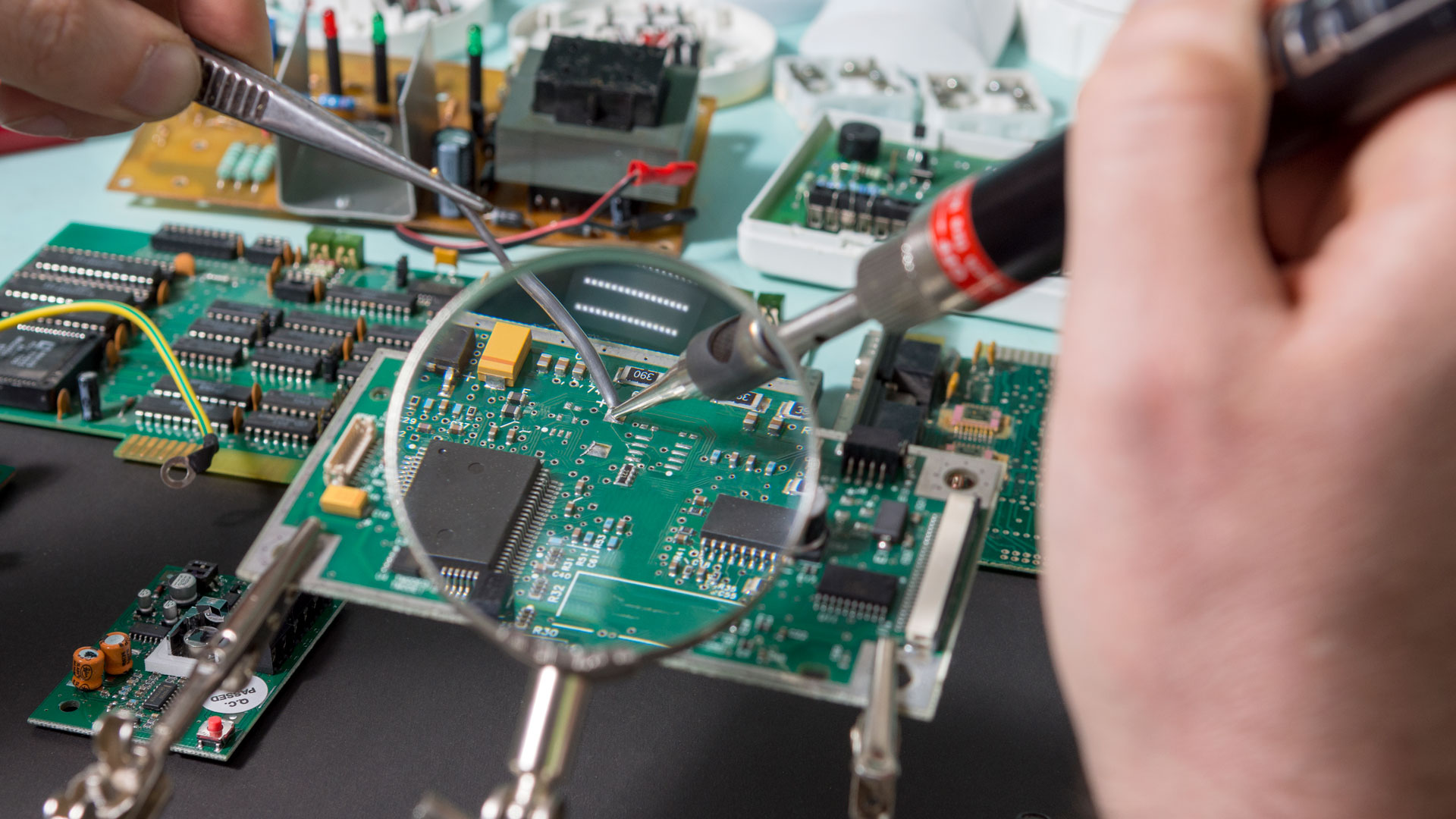

In modern electronics manufacturing, through-hole assembly and hand soldering are closely linked. While automation handles the majority of SMT processes, hand soldering remains essential for connectors, mechanical components, selective operations, rework, and low-volume builds.

As discussed in last week’s blog on through-hole assembly, many of the components that benefit most from through-hole construction also require manual soldering at some stage. For OEMs, the quality and control of hand soldering directly influence mechanical integrity, electrical performance, and long-term reliability.

Where Hand Soldering Fits in Through-Hole Assembly

Hand soldering is most commonly used when automated soldering methods are impractical or introduce unnecessary risk. This includes large connectors, mixed technology assemblies with bottom-side SMT components, mechanical hardware, and late-stage design changes.

Even when selective or wave soldering is used, hand soldering is often required for touch-up or completion of specific joints. Because these operations occur after primary SMT and reflow processes, defects introduced at this stage can be difficult to detect and costly to correct.

For this reason, hand soldering must be treated as a controlled manufacturing process, not a secondary or informal step.

Workmanship Standards Drive Consistency

Hand soldering quality is governed by the same workmanship expectations applied to automated soldering processes. Acceptance criteria define proper wetting, fillet formation, hole fill, and defect conditions for through-hole joints.

Applying consistent standards across SMT, through-hole, and hand-soldered operations ensures uniform quality expectations throughout the PCB assembly. It also eliminates ambiguity during inspection and customer acceptance.

For OEMs building products for high reliability or regulated markets, adherence to recognized workmanship standards is often non-negotiable.

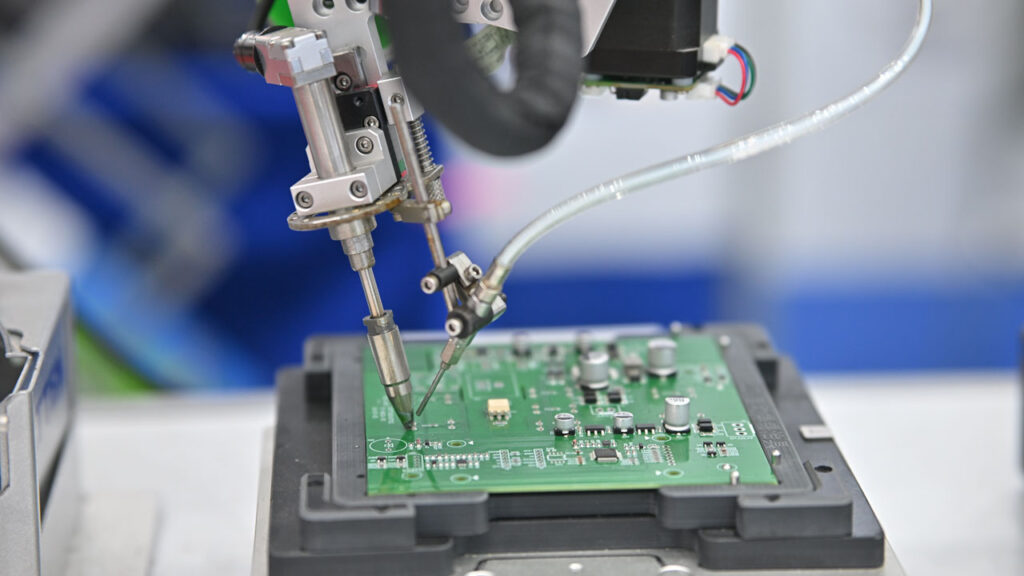

Operator Skill and Training Are Critical

Unlike automated processes, hand soldering relies heavily on operator skill and judgment. Without formal training and certification, results can vary significantly between technicians and even between shifts.

Best practice EMS providers maintain documented training programs, certification requirements, and periodic skill validation for hand-soldering operators. This is especially important when working with dense through-hole layouts, heavy copper boards, or components with high thermal mass.

Consistent operator capability is one of the most important factors in achieving repeatable hand soldering quality.

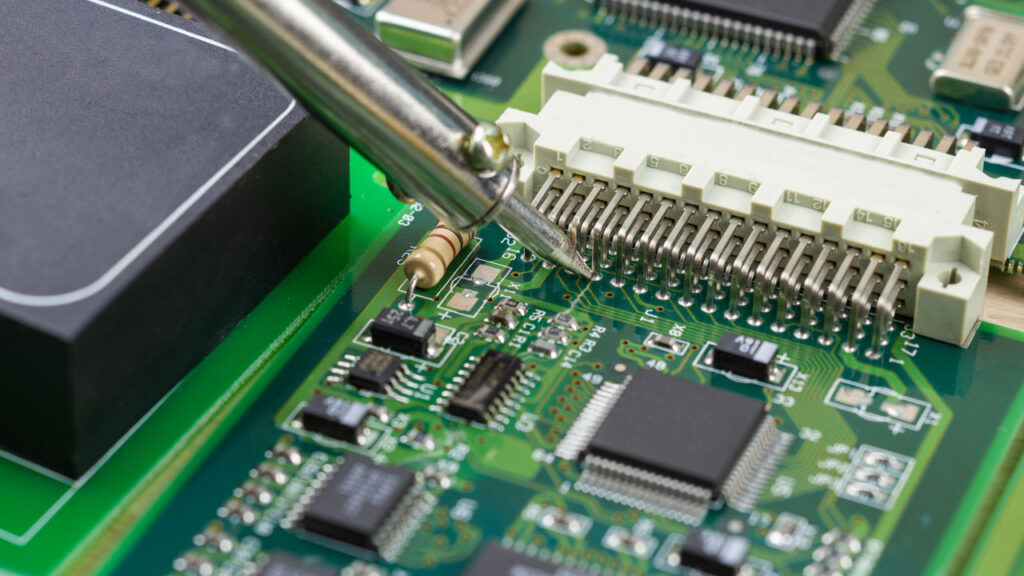

Equipment, Materials, and Thermal Control

Hand-soldering equipment must support precise temperature control and repeatability. Improper tip selection, excessive heat, or prolonged dwell time can damage components or compromise solder joint integrity.

Flux selection and application must also be controlled to ensure proper wetting while minimizing residue and contamination risk. These factors are particularly important for through-hole joints where complete hole fill and strong mechanical bonds are required.

Defined process parameters help reduce variability and protect both the assembly and the components being soldered.

Inspection of Hand Soldered Through-Hole Joints

Inspection criteria for hand-soldered through-hole joints focus on wetting, fillet geometry, hole fill, and evidence of overheating or damage. Visual inspection is the primary method, but accessibility and joint geometry can make inspection more challenging than SMT joints.

Clear inspection standards and trained inspectors help ensure consistent acceptance decisions. This is especially important for connectors and mechanical components where solder joint integrity directly affects field performance.

Inspection closes the loop between defined workmanship standards and actual production output.

Hand Soldering and Controlled Rework

Rework is another area where hand soldering intersects with through-hole assembly. Improper rework techniques can introduce more risk than the original defect.

Controlled rework procedures define how components are removed, cleaned, and resoldered while limiting thermal stress and preventing board damage. Documentation and traceability of rework activities are essential for maintaining product history and supporting root cause analysis.

OEMs benefit when rework is treated as a formal process with defined limits rather than an ad hoc repair.

What This Means for OEMs

Through-hole assembly and hand soldering are inseparable in many modern electronics builds. The reliability advantages of through-hole components can only be realized when hand-soldering processes are properly controlled.

OEMs should expect their EMS partner to apply the same discipline to manual soldering as they do to automated SMT processes. Defined standards, trained operators, controlled equipment, and robust inspection practices all contribute to consistent quality.

At Foxtronics EMS, hand soldering is fully integrated into our through-hole and mixed technology assembly workflows. By aligning workmanship standards, training, and inspection across all soldering processes, we help OEMs achieve reliable, repeatable results from prototype through production.