Table of Contents

Powering the Future of Industrial Automation

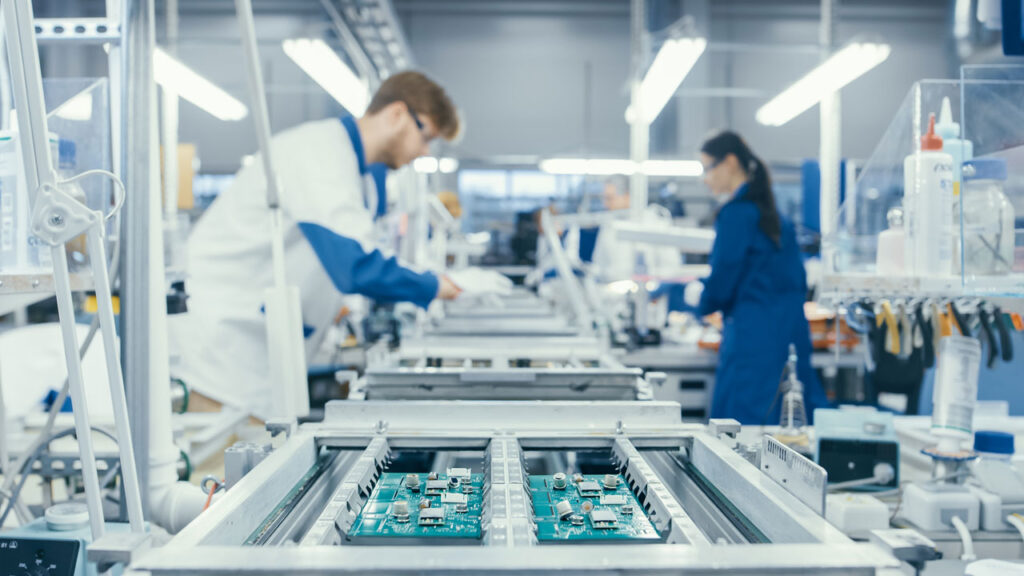

The world of industrial automation is evolving rapidly. Smart factories, robotics, and connected systems depend on electronics that perform with precision and consistency in the harshest environments.

At Foxtronics EMS, we specialize in manufacturing electronic (PCB) assemblies that drive the backbone of modern industry. From motor controllers and sensor boards to complete control modules, we deliver PCB assemblies designed for strength, reliability, and long service life.

The Growing Role of Electronics in Industrial & Automation Systems

Every modern industrial system relies on electronics for monitoring, control, and communication. Automation technologies such as programmable logic controllers, motor drives, and robotic systems require robust printed circuit board assemblies (PCBA) that can withstand vibration, temperature extremes, and electrical noise.

Foxtronics EMS supports these applications by combining high-reliability design practices with precise process control, ensuring every PCB assembly performs as intended in demanding industrial settings.

PCB Assembly Engineering for Harsh Industrial Environments

Industrial environments challenge electronics in ways that consumer products never experience. PCB assemblies must tolerate mechanical stress, dust, moisture, and temperature fluctuations while maintaining electrical integrity.

Foxtronics EMS engineers design and manufacture with these conditions in mind. Our PCB assemblies incorporate:

- Conformal coating and ruggedized finishes

- Wide temperature range components

- Mechanical reinforcement for connectors and heavy parts

- Controlled solder profiles for thermal stability

This focus on durability allows our products to deliver consistent performance in factories, field equipment, and power systems around the world.

Supporting Smart Factory and IIoT Technologies

As manufacturing becomes more connected, industrial automation now includes data collection, analytics, and remote monitoring through the Industrial Internet of Things. Foxtronics EMS supports this evolution with electronics designed for connectivity, real-time communication, and integrated control.

We produce assemblies for:

- Smart sensors and data acquisition systems

- Wireless communication modules

- Edge computing devices and gateways

- Machine control and monitoring units

Our expertise bridges traditional industrial control systems with next-generation digital manufacturing platforms.

Quality and Process Control for Industrial Reliability

In industrial automation, reliability is directly tied to process discipline. Foxtronics EMS applies process control and documentation, reinforced by advanced testing and integration solutions, to ensure consistency from prototype through full production.

Our quality systems include:

- Real-time monitoring of solder and placement parameters

- Automated optical and X-ray inspection

- Traceability of every component and production lot

- Functional testing under simulated load conditions

These measures ensure that each PCB assembly leaving our facility meets the standards for endurance and accuracy required in industrial & automation applications.

Collaboration from Design to Production

Foxtronics EMS works directly with industrial design and engineering teams to ensure manufacturability and cost effectiveness. Our engineers provide Design for Manufacturability (DFM) and Design for Test (DFT) feedback to optimize board layout, component selection, and assembly processes.

This collaborative design engineering approach allows customers to reduce development cycles, avoid late design changes, and accelerate time to market. By engaging Foxtronics EMS early, customers benefit from both technical insight and practical manufacturing experience.

Scalable Manufacturing for Diverse Industrial & Automation Applications

Industrial and automation customers often require both low-volume, high mix production for specialized control units and higher-volume production for standardized systems. Foxtronics EMS offers flexible manufacturing models to support both.

We provide:

- Rapid prototyping and pilot builds

- Lean, scalable production lines

- Build-to-order configurations

- Seamless transition from prototype to volume production

This flexibility ensures that we can meet customer needs across a wide range of industrial applications, from precision robotics to power management and automation infrastructure.

PCB Testing Strategies for Performance and Longevity

Industrial products are expected to last for years of continuous operation. Foxtronics EMS validates every PCB assembly through rigorous testing strategies to ensure it meets electrical, thermal, and functional requirements.

Our testing programs include:

- Functional load and power cycling tests

- Environmental stress screening

- Signal integrity and EMI verification

- Burn-in testing for reliability assurance

By simulating the conditions that PCB assemblies will face in the field, we ensure that our customers receive products built for endurance and performance.

Conclusion: Building the Electronics That Drive Industry

At Foxtronics EMS, we manufacture more than electronic assemblies; we create the systems that power automation, improve efficiency, and advance industrial innovation. Our commitment to precision, process control, and collaboration ensures that every board, cable, and control module performs reliably in mission-critical operations.

With Foxtronics EMS as your manufacturing partner, you gain a trusted source for electronics that strengthen the future of industrial automation.

If your automation or industrial control systems demand reliable, long-life electronics, Foxtronics EMS can help. Contact our team to learn how our manufacturing expertise supports industrial and automation programs worldwide.