Table of Contents

Safeguarding Electronics from the Elements

Every electronic product faces environmental challenges that can compromise performance and reliability. Moisture, dust, chemicals, and temperature variations can all degrade circuit integrity over time. That is where conformal coating plays a vital role.

At Foxtronics EMS, we apply conformal coating as part of our protective manufacturing process to shield printed circuit board assemblies from these environmental stresses. Our goal is simple: to ensure that every board we build continues to perform flawlessly in the field, no matter the conditions.

What Conformal Coating Is and Why It Matters

Conformal coating is a thin protective film applied to the surface of a printed circuit board. It conforms closely to component shapes and solder joints, creating a barrier that resists moisture, dust, and contaminants.

Unlike potting compounds that fully encapsulate an assembly, conformal coatings provide lightweight protection while allowing serviceability and inspection. This makes them ideal for a wide range of applications where space, weight, and performance are critical.

Common benefits include:

- Prevention of corrosion and short circuits

- Improved electrical insulation

- Resistance to vibration and mechanical stress

- Extended product lifespan

By applying the right coating type and thickness, Foxtronics ensures lasting protection without affecting thermal performance or testability.

Materials Used in Conformal Coating

Selecting the correct coating material is key to achieving the desired protection and performance balance. Foxtronics EMS works with several industry-standard chemistries, each suited to different environments and requirements.

The most common coating materials include:

- Acrylic: Easy to apply and rework, excellent moisture protection

- Silicone: High flexibility and temperature resistance

- Urethane: Strong chemical and abrasion protection

- Epoxy: Exceptional durability for harsh conditions

- Parylene: Ultra-thin vapor deposition for maximum uniformity and insulation

Each coating is selected based on the product’s environment, voltage requirements, and mechanical demands.

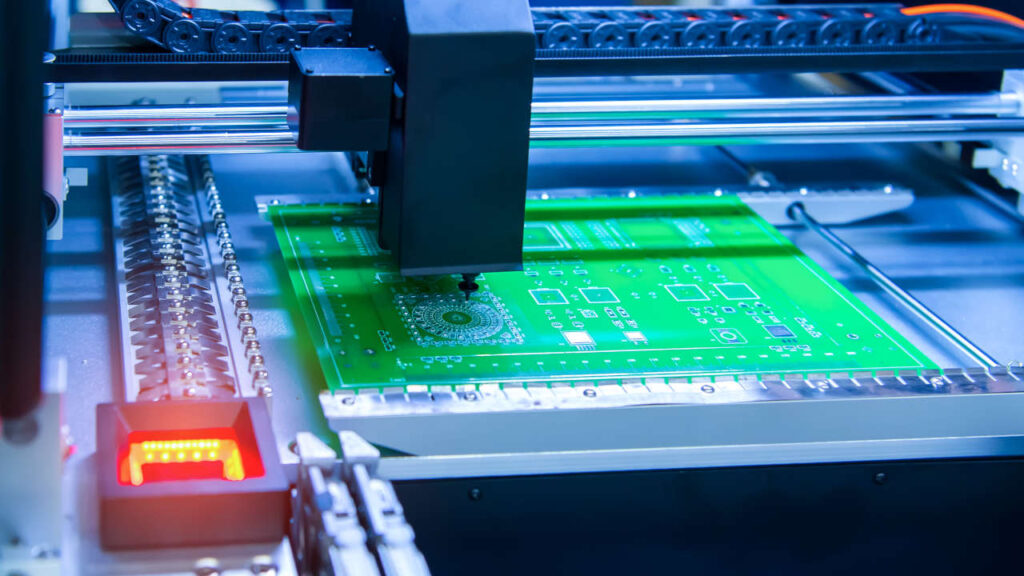

Application Methods for Consistent Coverage

At Foxtronics, we use several controlled application methods to achieve uniform and reliable coating coverage. The method is selected based on the board design, component density, and masking requirements.

Our processes include:

- Selective robotic coating for precision targeting around sensitive components

- Spray coating for uniform coverage on larger areas

- Dip coating for high-volume assemblies

- Brush touch-up for localized protection

Before coating, we perform meticulous cleaning to remove flux residues or contaminants that could trap moisture under the film. Every board is inspected under UV light to confirm complete and even coverage.

Masking and Process Control

Masking is one of the most important steps in the conformal coating process. Certain areas, such as connectors, test points, and heat sinks, must remain uncoated for electrical or thermal reasons.

Foxtronics EMS uses custom masking techniques, including tapes, boots, and plugs, to ensure that these areas remain protected during application. After coating, each PCB assembly undergoes curing in controlled environments to achieve proper adhesion and mechanical properties. We track every process parameter, from material batch to curing time, to guarantee repeatable results.

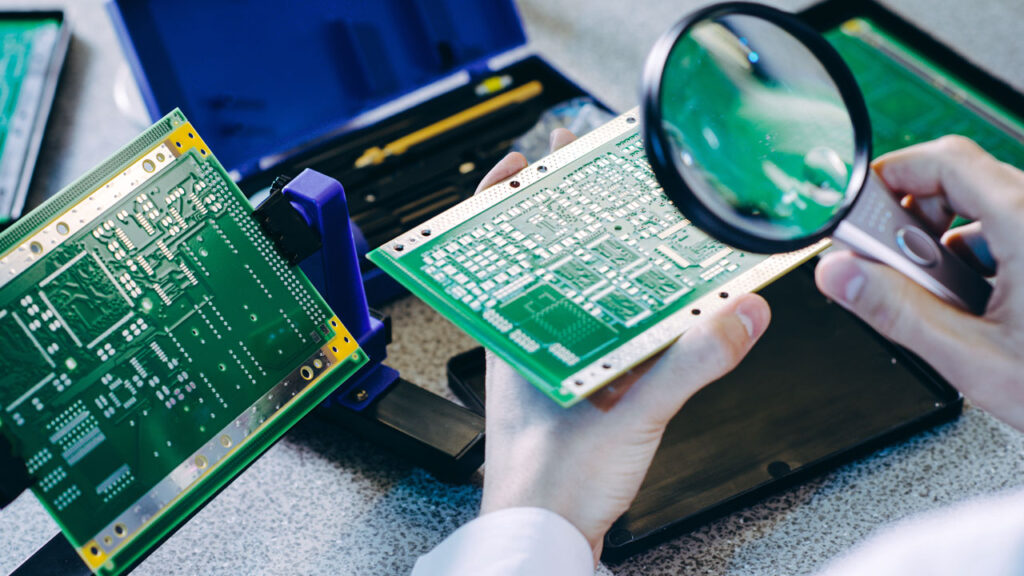

Inspection and Verification

Verification is essential to confirm that the coating provides complete protection. Foxtronics inspects every coated PCB assembly under ultraviolet light, revealing even the smallest gaps or bubbles in coverage.

We also perform cross-section and adhesion testing to ensure long-term durability. For critical applications such as aerospace, medical, and industrial controls, coating thickness is measured using calibrated gauges to meet exact specifications. This commitment to process control ensures that the coating will perform consistently over the years of use.

When to Use Conformal Coating

Not every product requires conformal coating, but many benefit significantly from it.

Foxtronics recommends coating for assemblies exposed to:

- High humidity or condensation

- Chemical or salt air environments

- Wide temperature swings or mechanical vibration

- Outdoor or industrial use cases

Even for controlled indoor environments, coating can enhance product reliability by preventing microcorrosion and particulate buildup.

Integration with the Manufacturing Process

Because Foxtronics EMS manages coating in-house, we integrate this step directly into our overall production flow. Boards move from cleaning and inspection into coating, curing, and final testing without leaving the facility.

This integrated approach reduces handling risk, shortens lead times, and ensures full traceability from bare board to finished product. Every coated assembly is documented, serialized, and traceable within our quality system.

Conclusion: Protecting Performance from the Inside Out

At Foxtronics EMS, we view conformal coating as more than a finishing step, it is an essential part of product reliability engineering. By combining precise application, rigorous inspection, and careful material selection, we provide lasting protection for even the most demanding environments.

Our customers rely on us to deliver PCB assemblies that stand up to time, temperature, and testing, and conformal coating is one of the tools that makes that possible.

If your products operate in challenging environments, Foxtronics EMS can help protect them. Contact our team to learn more about our conformal coating and PCB protection capabilities.