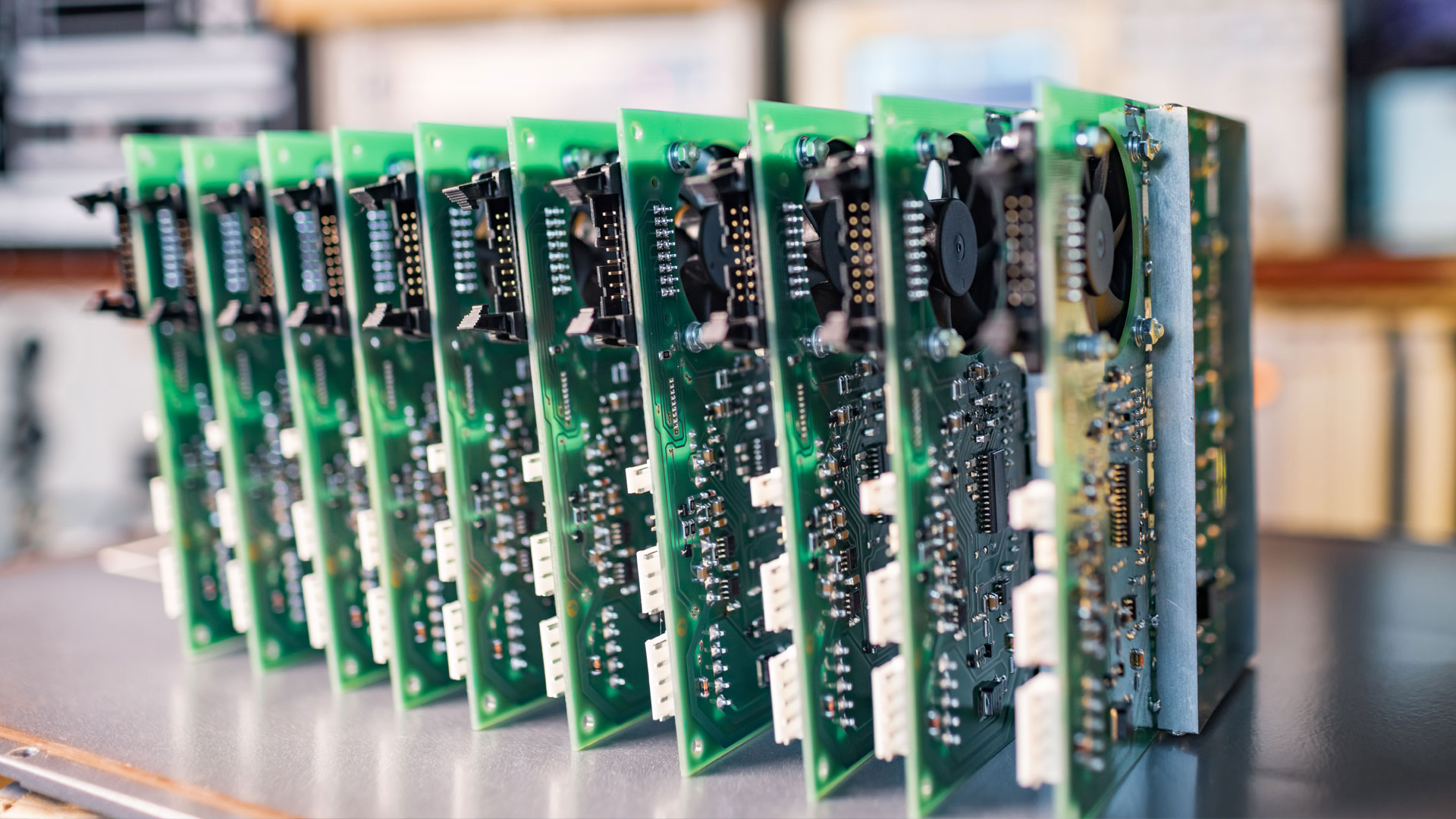

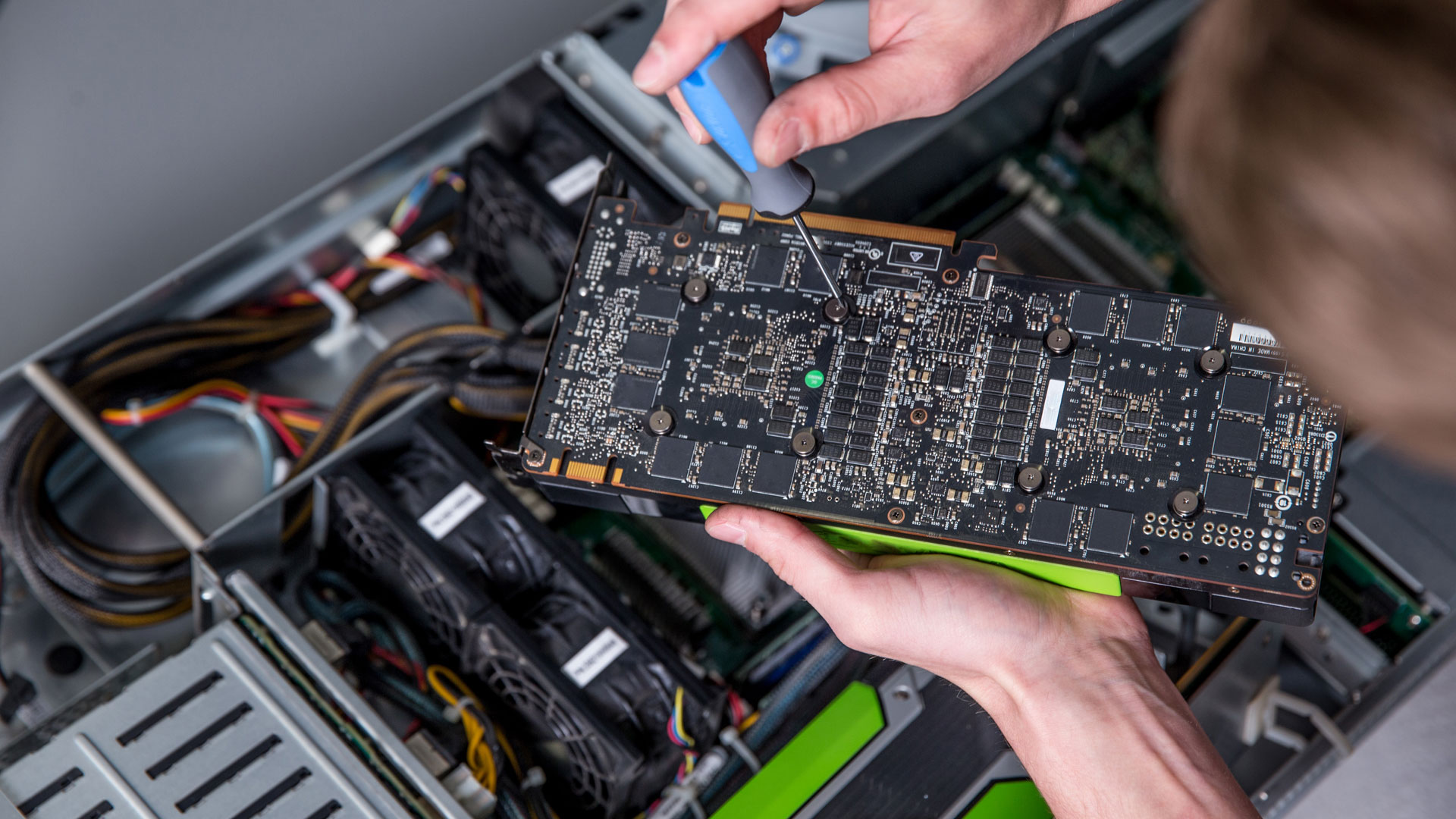

At Foxtronics EMS, we understand that speed, accuracy, and agility are critical during the early stages of product development. Our PCB Prototyping and New Product Introduction (NPI) services are built to help you go from concept to market faster while maintaining the highest standards of quality and performance. Whether you’re creating cutting-edge aerospace systems, medical electronics, or high-reliability industrial controls, our team ensures your designs are validated, tested, and optimized for scalable production.

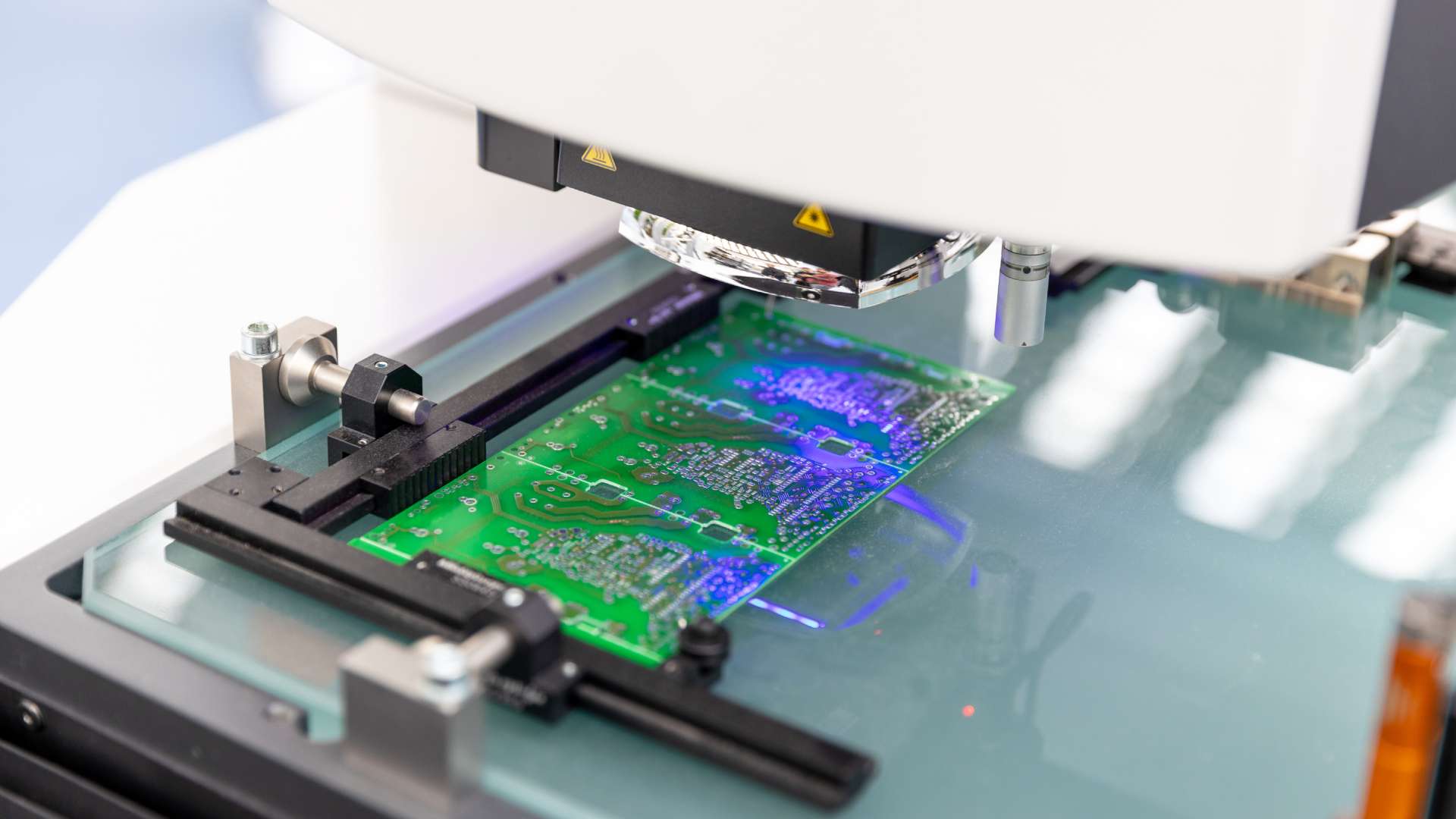

Our comprehensive PCB prototyping capabilities include rapid PCB fabrication, low-volume assembly, and thorough design for manufacturability (DFM) reviews. We help identify potential production issues early, enabling cleaner layouts, better material selection, and fewer redesigns down the road. By integrating tightly with our engineering teams and leveraging advanced PCBA manufacturing technologies across our U.S. facilities, we streamline your NPI process while supporting a wide range of board types—from rigid to HDI, flex, and more.

With vertically integrated operations and IPC-certified processes, Foxtronics EMS reduces development time and enhances the reliability of your final product. Our U.S.-based fast-turn PCB prototyping services are not just about speed; they’re about building a strong foundation for full-scale production. We serve as a proactive partner through every iteration, ensuring your product is ready for launch with minimal risk and maximum efficiency.