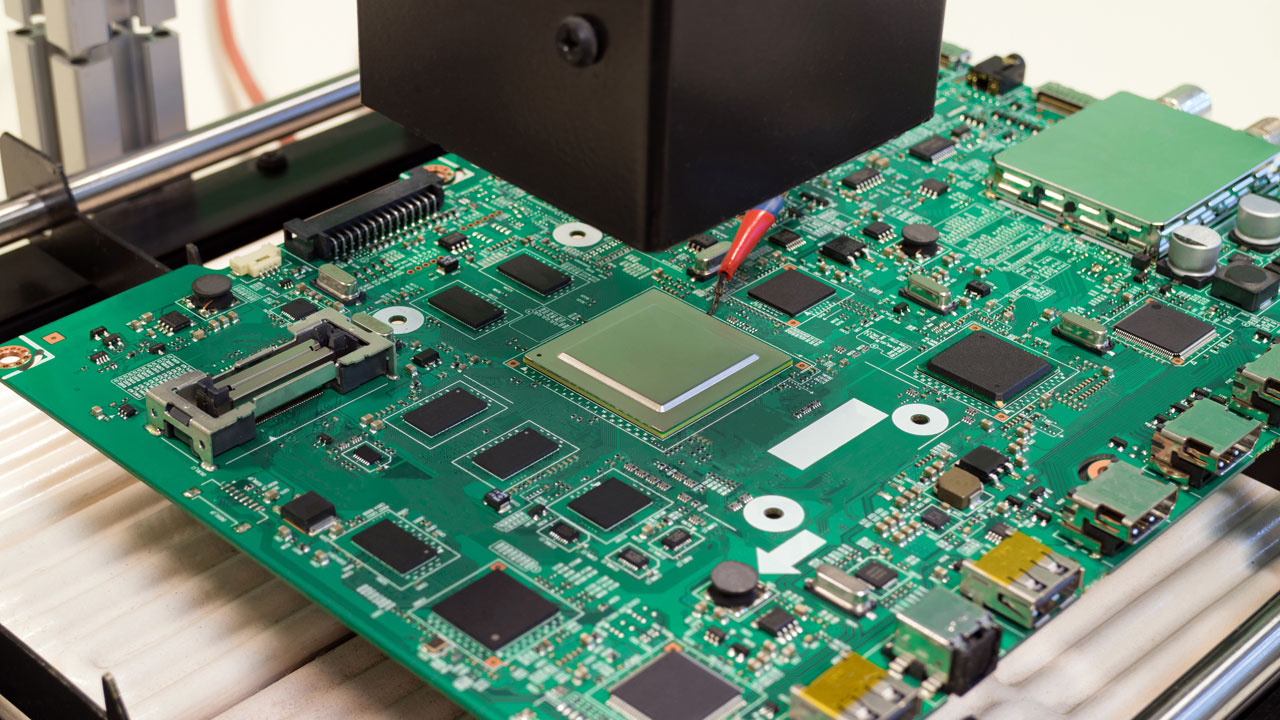

In today’s fast-paced innovation landscape, not every product requires mass production, but every product does demand quality, consistency, and agility. High mix, low volume (HMLV) production is essential for manufacturers building a diverse range of electronic assemblies in smaller quantities. Whether it’s a lineup of product variants, frequent design iterations, or low-demand specialized PCB assemblies, HMLV enables flexibility without sacrificing production standards.

Foxtronics EMS excels in managing complexity, change, and customization. From handling diverse BOMs and varying circuit board layouts to accommodating mixed-technology assembly, we streamline every stage of HMLV PCBA production. Our engineering and production teams are experienced in balancing short-run agility with rigorous quality control, ensuring each unit is built to spec, regardless of how unique the build is.

With the combined strength of our group companies—Accutron, OSDA, CCK Automations, and Argo EMS—we offer purpose-built facilities, robust traceability, and highly responsive PCBA production capabilities. Whether you’re building 10 units or 1,000 across multiple configurations, we keep your project moving efficiently with scalable, repeatable results.