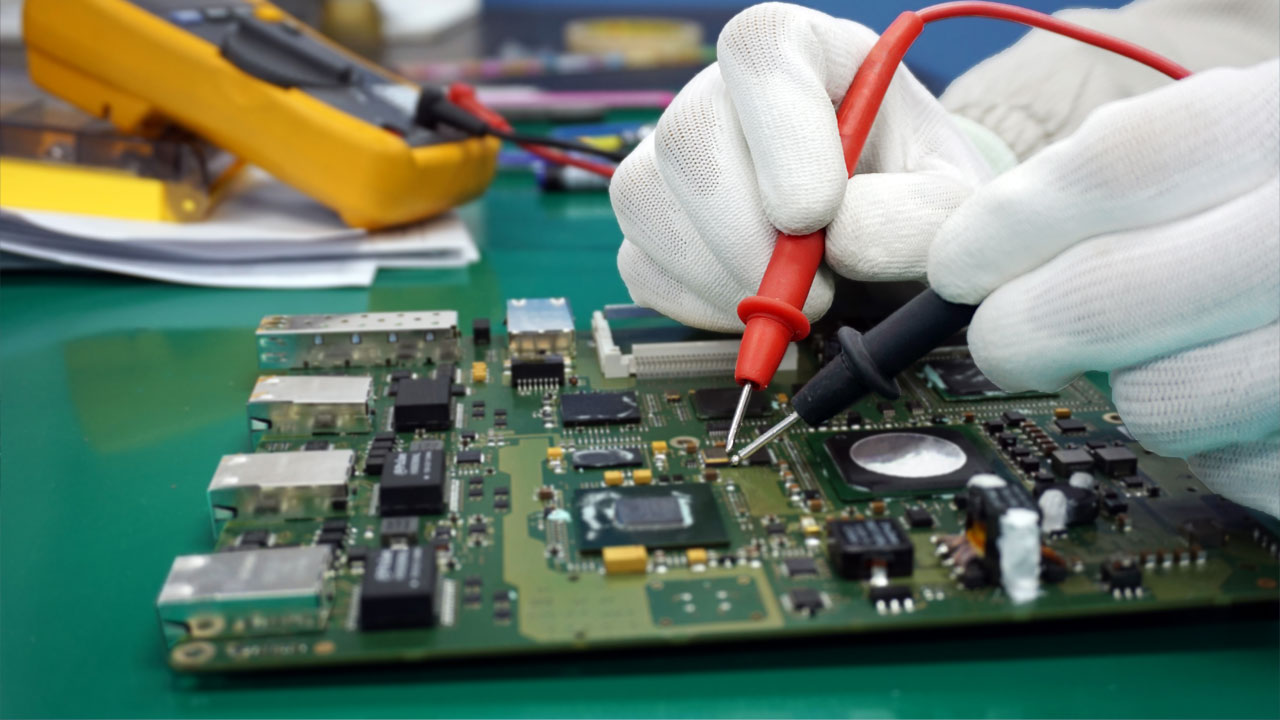

In today’s fast-paced electronics market, delivering a product that simply powers on is no longer enough. Complex PCB assemblies must function flawlessly under real-world conditions, meet rigorous safety and compliance standards, and integrate seamlessly with surrounding systems. That’s why Testing & Integration plays a critical role in every stage of our manufacturing process at Foxtronics EMS.

Whether it’s In-Circuit Testing (ICT), Functional Circuit Testing (FCT), Flying Probe Testing for prototypes, or advanced X-ray and optical inspections, Foxtronics EMS covers all essential checkpoints. We also perform environmental stress screening and burn-in tests to assess durability in real-world conditions. Our services go beyond printed circuit board assembly; we offer complete system-level and box build testing to ensure every integrated product meets its functional and quality targets before delivery.

With built-in test coverage analysis, real-time reporting, and custom fixture development, we offer not only testing but also the assurance that your products are production-ready, reliable, and compliant with global quality standards.