PCB Assembly for Aerospace & Defense

High-reliability PCB assembly Services and system-level manufacturing for aerospace and defense programs. AS9100-certified, traceable, and built for mission-critical performance.

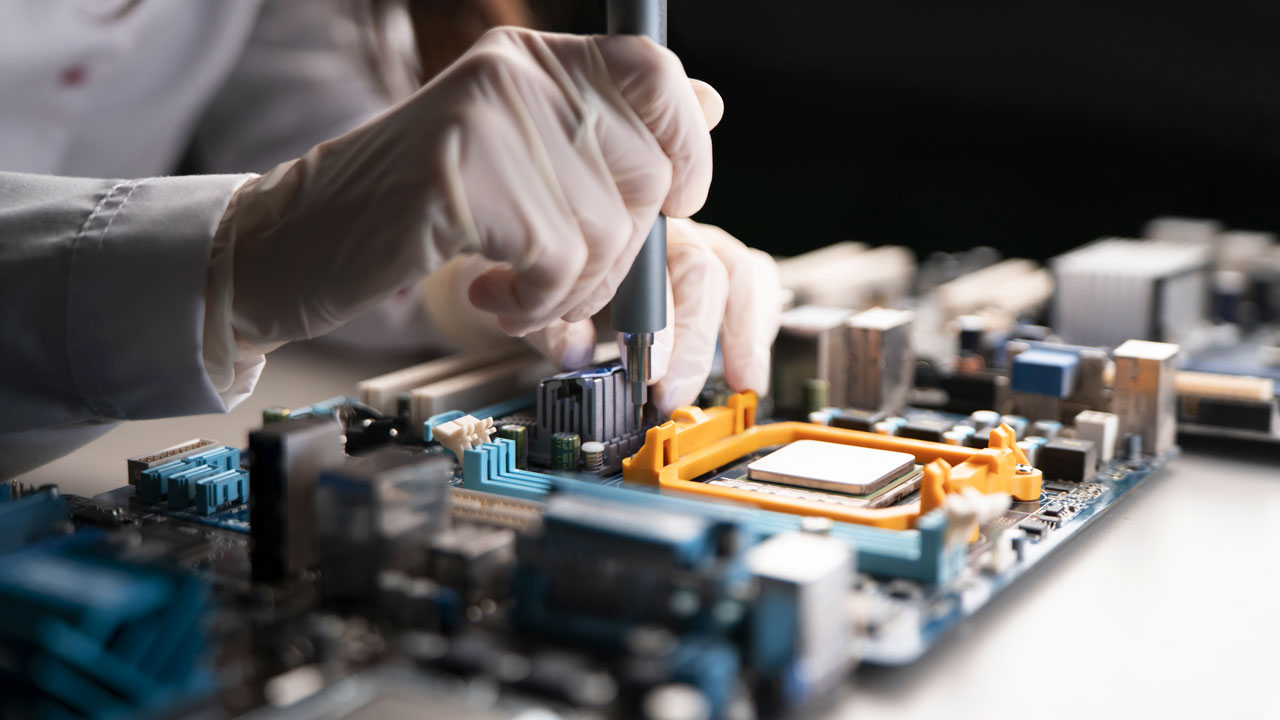

Aerospace and defense electronics endure the toughest conditions, from constant vibration and extreme temperatures to high altitudes and electromagnetic interference. Every PCB Assembly component, solder joint, and circuit pathway must perform flawlessly because lives and missions depend on it.

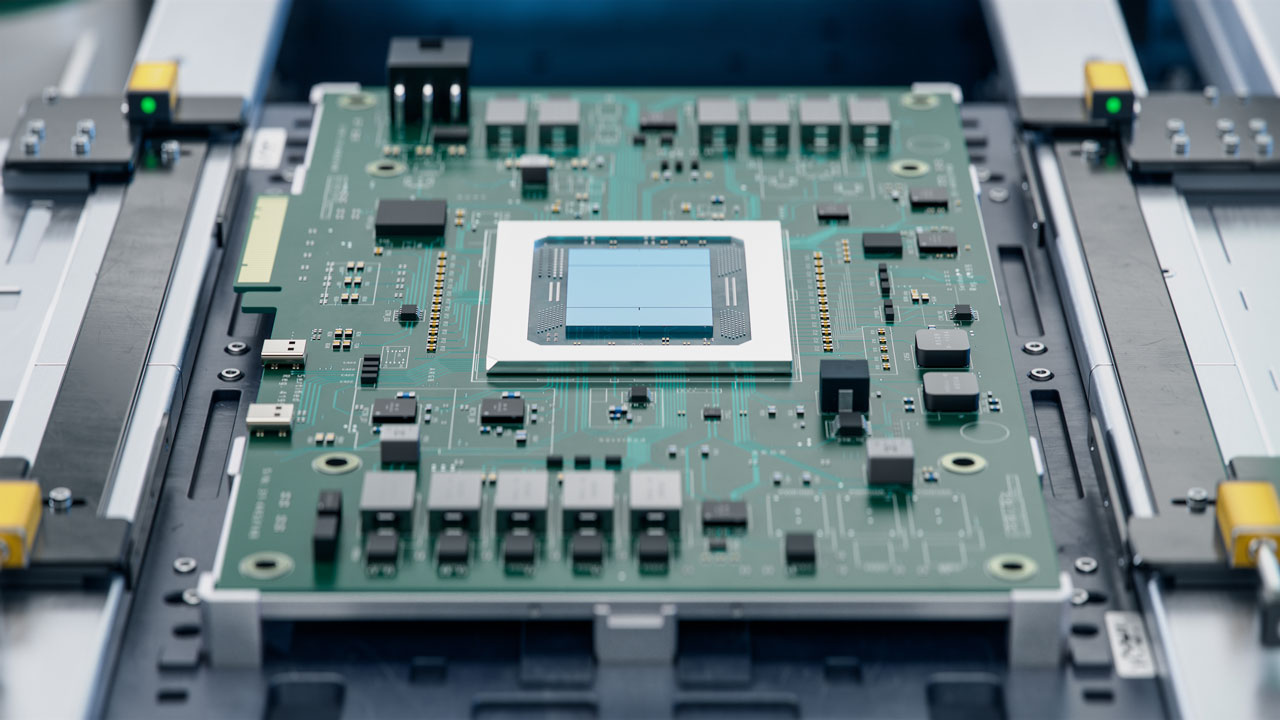

Foxtronics EMS brings deep domain expertise to aerospace and defense electronics manufacturing. We partner with OEMs to design, assemble, and integrate high-reliability PCB assemblies for flight control, radar, communication, satellite, and tactical systems. Each build is produced in AS9100D-certified and ITAR-registered facilities, ensuring compliance with global aerospace and defense quality frameworks.

Our aerospace and defense PCB assembly manufacturing process integrates Design for Manufacturability (DFM) expertise, rapid prototyping, and controlled production environments to help OEMs reduce risk, accelerate validation, and achieve higher first-pass yields. From rapid prototyping and design validation to high-mix, low-volume production runs, our engineering teams work as an extension of yours, delivering consistency, precision, and program-level accountability at every manufacturing step.

Foxtronics EMS delivers advanced ruggedization through protective conformal coatings and environmental protection, combined with rigorous environmental testing protocols, ensuring aerospace and defense PCB assemblies withstand extreme operational conditions in air, land, and space environments.

Aerospace and defense systems require electronics that are not only precise but also resilient. The industry demands uncompromising performance under mechanical shock, temperature fluctuations, and electromagnetic interference. Beyond performance, manufacturers must guarantee traceability, regulatory compliance, and documented quality at every step of the way.

At Foxtronics EMS, we understand these expectations in depth. Our processes are purpose-built for aerospace-grade manufacturing, following strict AS9100D standards and ITAR compliance. Every aerospace and defense build is managed with traceability and compliance in PCB assembly manufacturing, ensuring serialized tracking, comprehensive documentation control, and program-level accountability that withstands rigorous audits.

With experience spanning avionics, UAV systems, guidance controls, and satellite communications, we bridge the gap between engineering intent and manufacturing precision. From supply chain and component sourcing to BOM integrity, coating, ruggedization, and final build testing, our systems are designed to meet the unique challenges of this high-stakes industry. Our teams don’t just build products; they build confidence in every mission-critical system we deliver.

Whether you're building guidance systems, avionics modules, or military communications hardware, our facilities and processes are equipped to support demanding, standards-driven programs.

From prototype PCB assemblies to full system-level integrations, Foxtronics EMS provides complete, certified, and traceable manufacturing solutions that meet aerospace and defense requirements for precision, performance, and reliability.

Utilizing advanced SMT and through-hole assembly technologies for complex, multilayer aerospace PCB assemblies, every build follows AS9100D-certified and ITAR-compliant processes. Our controlled lines deliver Class 3 quality with repeatable precision, ensuring mission-critical electronics operate reliably across flight, radar, and defense communication systems.

All aerospace-grade electronics assemblies meet or exceed IPC-A-610 Class 3 workmanship standards—the benchmark for high-reliability aerospace and defense manufacturing. Robust solder joints, precise tolerances, and zero-defect quality ensure consistent performance in demanding mission environments.

We provide turnkey box build and system integration for the aerospace and defense industry, offering complete assembly and integration of subsystems, control units, and ruggedized enclosures with comprehensive wiring, harnessing, and mechanical assembly, delivering production-ready aerospace and military modules from PCB assembly to fully tested systems.

Protective coatings and encapsulation techniques safeguard aerospace-grade PCB assemblies from vibration, humidity, and temperature extremes. Each unit undergoes visual inspection, cure validation, and environmental testing to ensure mission-critical durability under the most demanding operational conditions.

Each aerospace and defense assembly undergoes rigorous validation through comprehensive PCB assembly testing strategies, including ICT, AOI, X-ray inspection, and environmental stress screening. We ensure full compliance with program-specific test plans to verify operational integrity, durability, and mission readiness.

Every aerospace and defense PCB build is documented through serialized traceability and digital recordkeeping, in line with AS9100D and ITAR compliance requirements. Full BOM control, process validation, and audit-ready documentation ensure mission-critical quality assurance from prototype through production.

Foxtronics EMS is more than just a PCB Assembly manufacturer. We are a trusted partner for OEMs developing products for aerospace and defense programs that must perform reliably every time, in every condition. Our design engineering expertise, disciplined processes, and compliance-driven systems combine to deliver high-performance electronics for the aerospace and defense industry with predictable quality and traceable assurance.

As a vertically integrated AS9100D-certified EMS company, we coordinate seamlessly across design, component sourcing, and production stages to ensure flawless execution. Our team collaborates early with customers to align design intent, manufacturability, and testing requirements, reducing risk across complex defense programs. This integration extends to our supply chain management systems, ensuring every part and process meets global traceability and delivery standards.

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Explore answers to common questions about our AS9100-certified aerospace and defense PCB assembly, compliance standards, and how we deliver mission-critical reliability from design to final production.

We manufacture PCB assemblies and integrated systems for flight control modules, UAV electronics, satellite communications, radar control units, and military-grade components.

Yes. We are AS9100D-certified, IPC-A-610 Class 3 capable, and ITAR-registered, with full process documentation.

Every project follows serialized tracking and digital recordkeeping for complete component and process traceability in accordance with aerospace and defense program requirements.

Yes, we specialize in low- to mid-volume, high-mix production for complex PCB assemblies common in aerospace and defense electronics.

Absolutely. We provide selective conformal coating, potting, and environmental stress testing to ensure reliability under extreme operational conditions. Learn more about our testing and integration services.