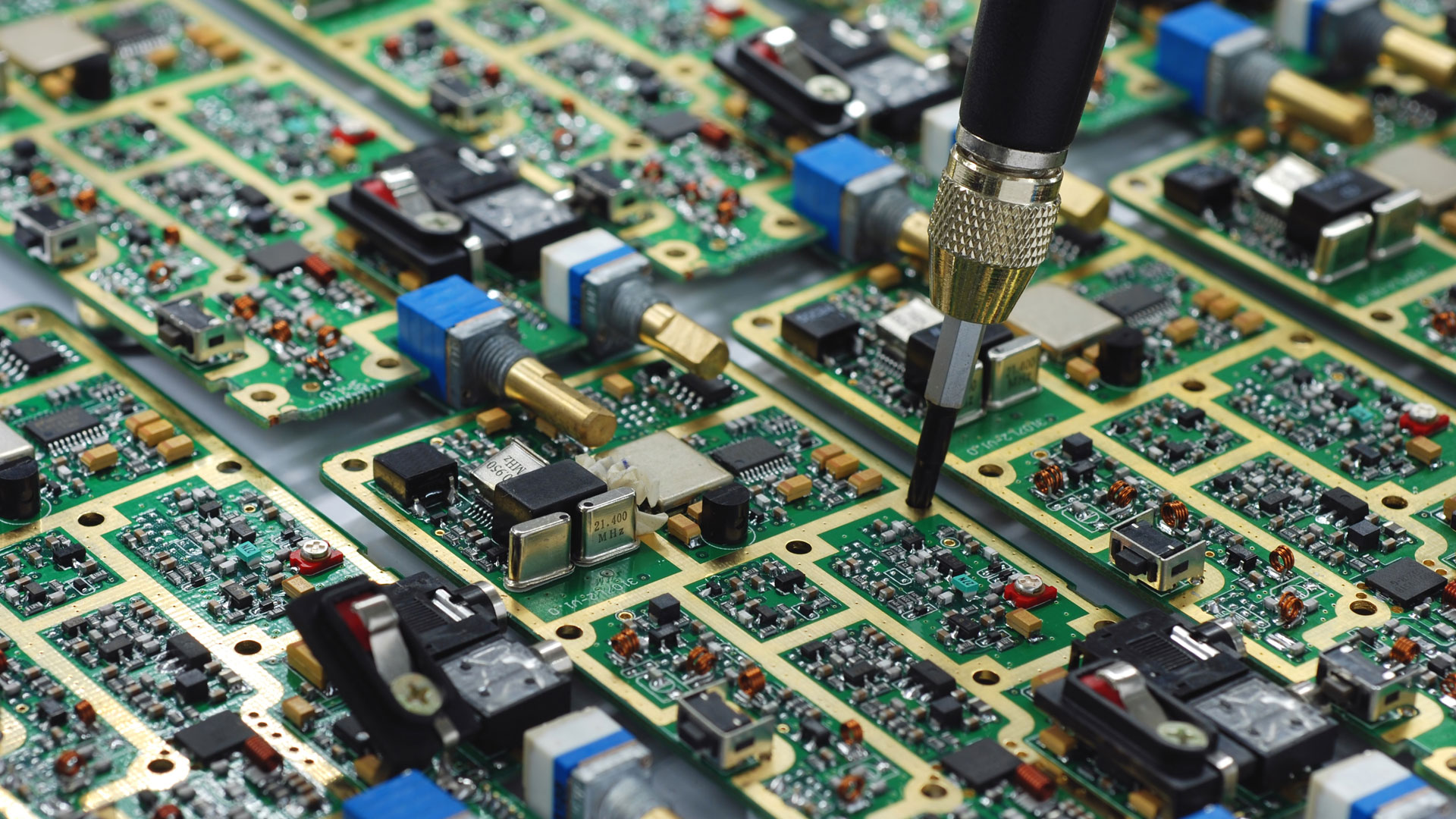

As a leading PCB assembly manufacturer in the USA, Foxtronics EMS delivers precision-engineered printed circuit board assemblies for high-density, high-speed, and high-reliability applications. With capabilities spanning HDI, flex, rigid-flex, RF/microwave, and microelectronics PCBAs, we support cutting-edge innovations across industries like aerospace, medical, industrial automation, and communications.

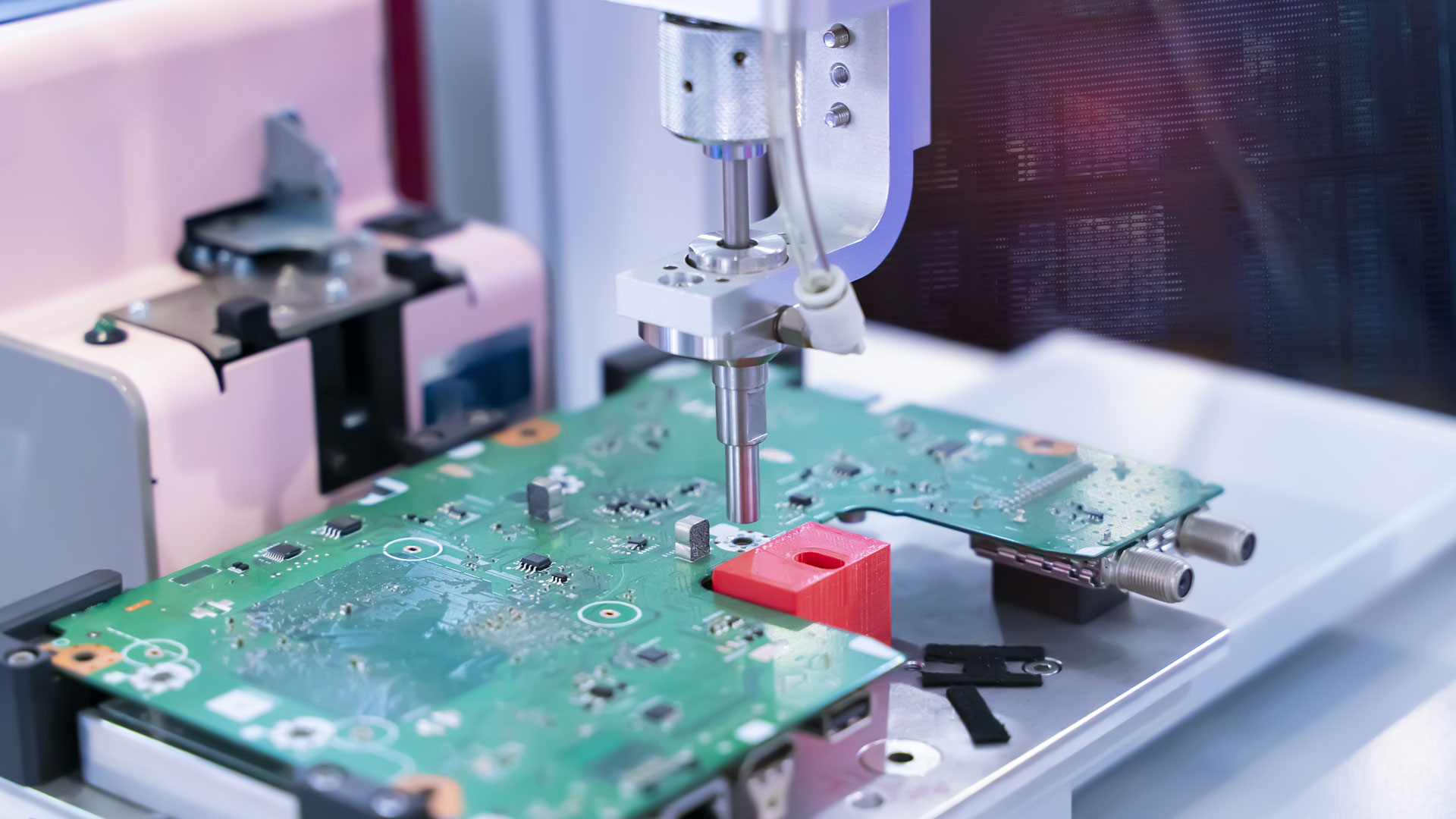

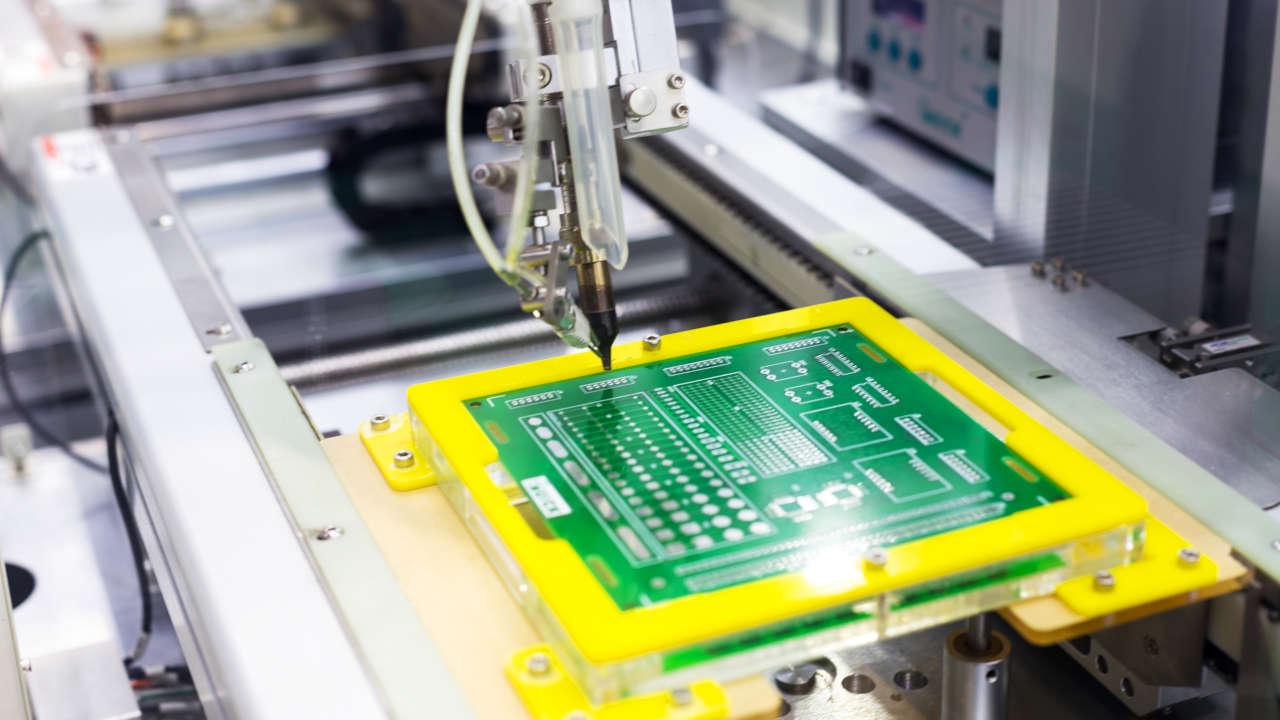

Our advanced PCB assembly manufacturing facilities in the U.S. are equipped with state-of-the-art fabrication and inspection technologies that ensure performance, signal integrity, and consistency from rapid prototyping through high-volume production. We partner closely with customers to meet complex electrical, thermal, and mechanical requirements while optimizing for cost, materials, and manufacturability.

From multilayer HDI boards to ultra-thin flex circuits and high-frequency RF PCBAs, our team of engineers and manufacturing experts is committed to delivering solutions that drive your products forward. With vertically integrated processes and a deep understanding of next-gen electronics, Foxtronics EMS is your trusted partner for advanced PCBA manufacturing in North America.