Table of Contents

As PCB assemblies grow more complex, inspection alone is no longer enough to ensure functional integrity. While automated optical inspection (AOI) excels at identifying visual and placement defects, electrical testing is required to verify that circuits are built correctly and perform as intended.

Two of the most common electrical test methods used in electronics manufacturing are in-circuit testing and flying probe testing. Understanding the differences between these approaches helps OEMs select the right strategy based on volume, complexity, and risk.

Why Electrical Testing Is Critical?

Electrical defects are not always visible. Open circuits, shorts, incorrect component values, and assembly-induced damage can exist even when a board looks perfect.

Electrical testing validates connectivity, component presence, polarity, and, in many cases, basic functionality. When used alongside AOI and process controls, it significantly reduces the likelihood of defective PCB assemblies reaching later production stages or the field.

What Is In Circuit Testing?

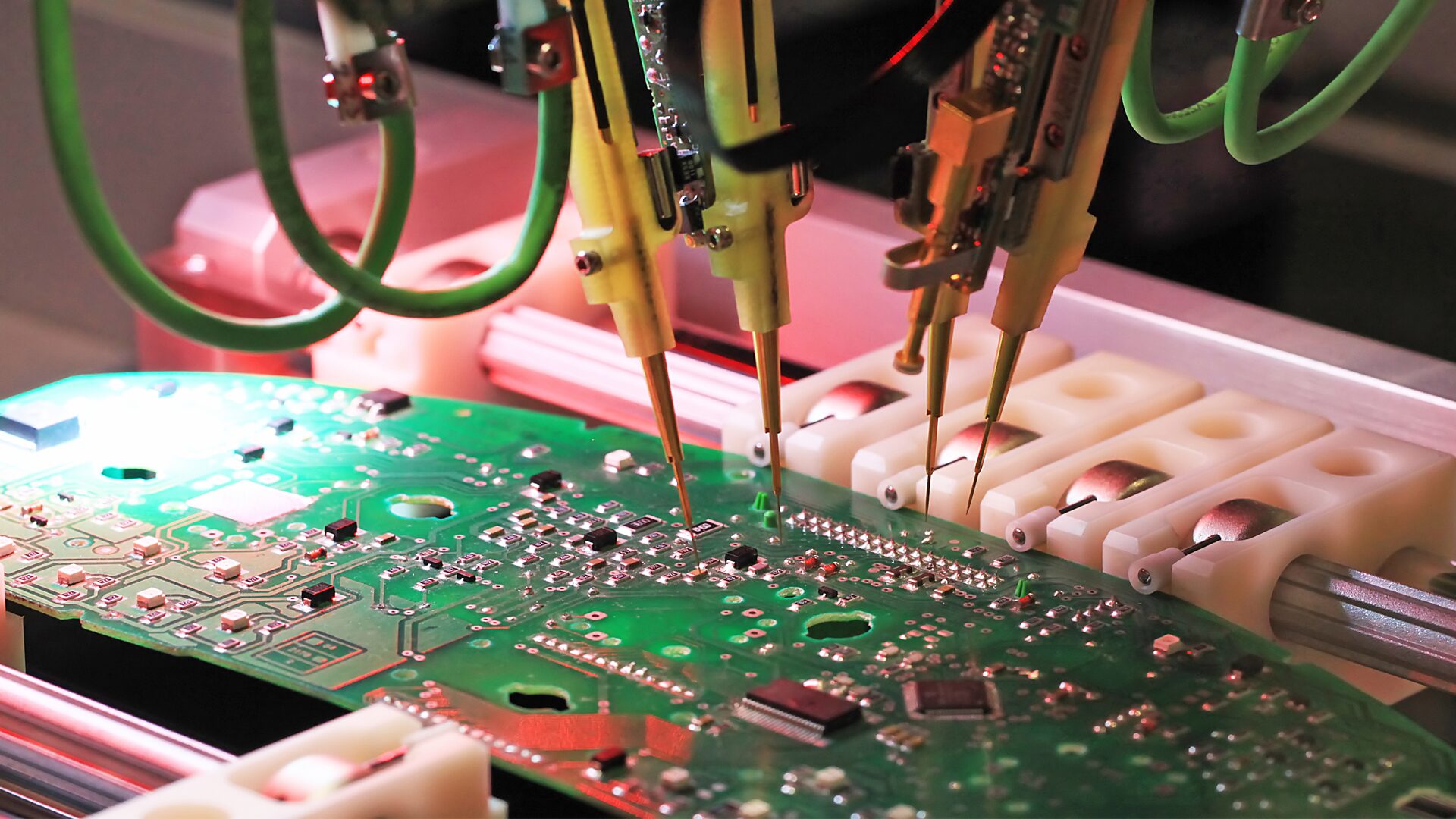

In-circuit testing, often referred to as ICT, uses a fixture with physical test probes that contact dedicated test points on the PCB. These probes apply signals and measurements directly to individual nets and components.

ICT provides fast, repeatable testing with high coverage when boards are designed for it. It can detect opens, shorts, incorrect values, missing components, and some solder defects. Because tests are performed simultaneously through a fixture, ICT is well-suited for higher volume production where cycle time matters.

However, ICT requires upfront investment in fixture design and fabrication. It also relies on adequate test point access, which must be considered early in the PCB layout process.

What Is Flying Probe Testing?

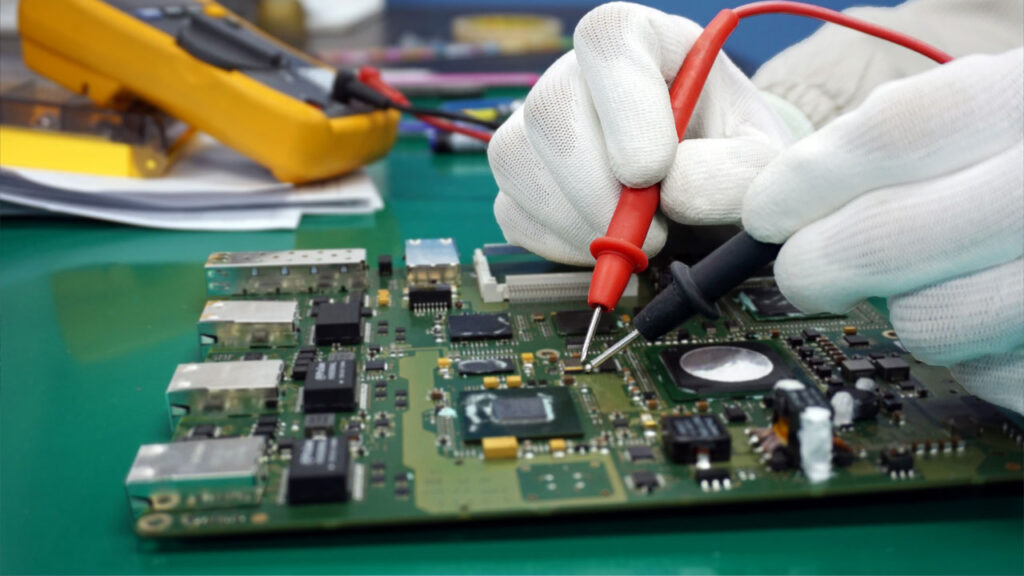

Flying probe testing uses movable probes that contact test points sequentially rather than through a fixed fixture. This eliminates the need for custom fixtures and allows tests to be programmed directly from design data.

Flying probe testing is especially valuable for prototypes, low-volume builds, and designs that change frequently. It provides flexibility and quick setup, making it ideal for early development stages or products with limited test access.

The tradeoff is speed. Because probes move sequentially, flying probe testing is typically slower than ICT and may not be suitable for high-volume production.

Coverage and Design Considerations

Test coverage depends heavily on how the PCB is designed. ICT benefits from clearly defined test points, accessible nets, and stable layouts. Flying probe testing can work with fewer test points, but still requires thoughtful design to maximize effectiveness.

OEMs that involve their EMS partner early can optimize designs for testability. Small layout adjustments during design can significantly improve test coverage and reduce long-term testing costs.

Design for testability is often the difference between effective testing and limited visibility into product quality.

Speed, Cost, and Scalability Tradeoffs

ICT offers the fastest test times once fixtures are in place, making it cost-effective at scale. The initial fixture cost is offset over production volume.

Flying probe testing avoids fixture costs and supports rapid iteration, but longer test times can become a bottleneck as volume increases.

Many EMS providers use both methods strategically. Flying probe testing supports early builds and engineering validation, while ICT is introduced as products move into sustained production.

Reliability and Failure Analysis Benefits

Electrical testing plays a key role in reliability and failure analysis. Test results can be logged and linked to serial numbers, supporting traceability and root cause investigations.

When defects are detected early, manufacturers can isolate process issues before they impact yield or customer deliveries. This aligns testing with continuous improvement rather than treating it as a final gate.

Choosing the Right Test Strategy

There is no universal answer to which test method is best. The right approach depends on product complexity, volume, lifecycle stage, and reliability requirements.

OEMs benefit most when right testing strategies are defined collaboratively with their EMS partner. Aligning inspection, electrical testing, and functional validation creates a balanced quality system that supports both speed and confidence.

What This Means for OEMs

In circuit testing and flying probe testing, each serves distinct roles in modern PCB assembly. Understanding their strengths and limitations allows OEMs to make informed decisions that reduce risk and support scalable production.

At Foxtronics EMS, we apply both testing methods as part of a layered quality strategy. By aligning test selection with product requirements and production goals, we help OEMs achieve reliable results from prototype through volume manufacturing.

Contact us today to discuss the right approach for your next build.