Robust packaging and environmental protection are essential for electronic assemblies that operate in real-world conditions. At Foxtronics EMS, our injection molding and coating services are engineered to provide supporting functional integration, mechanical strength, and long-term reliability.

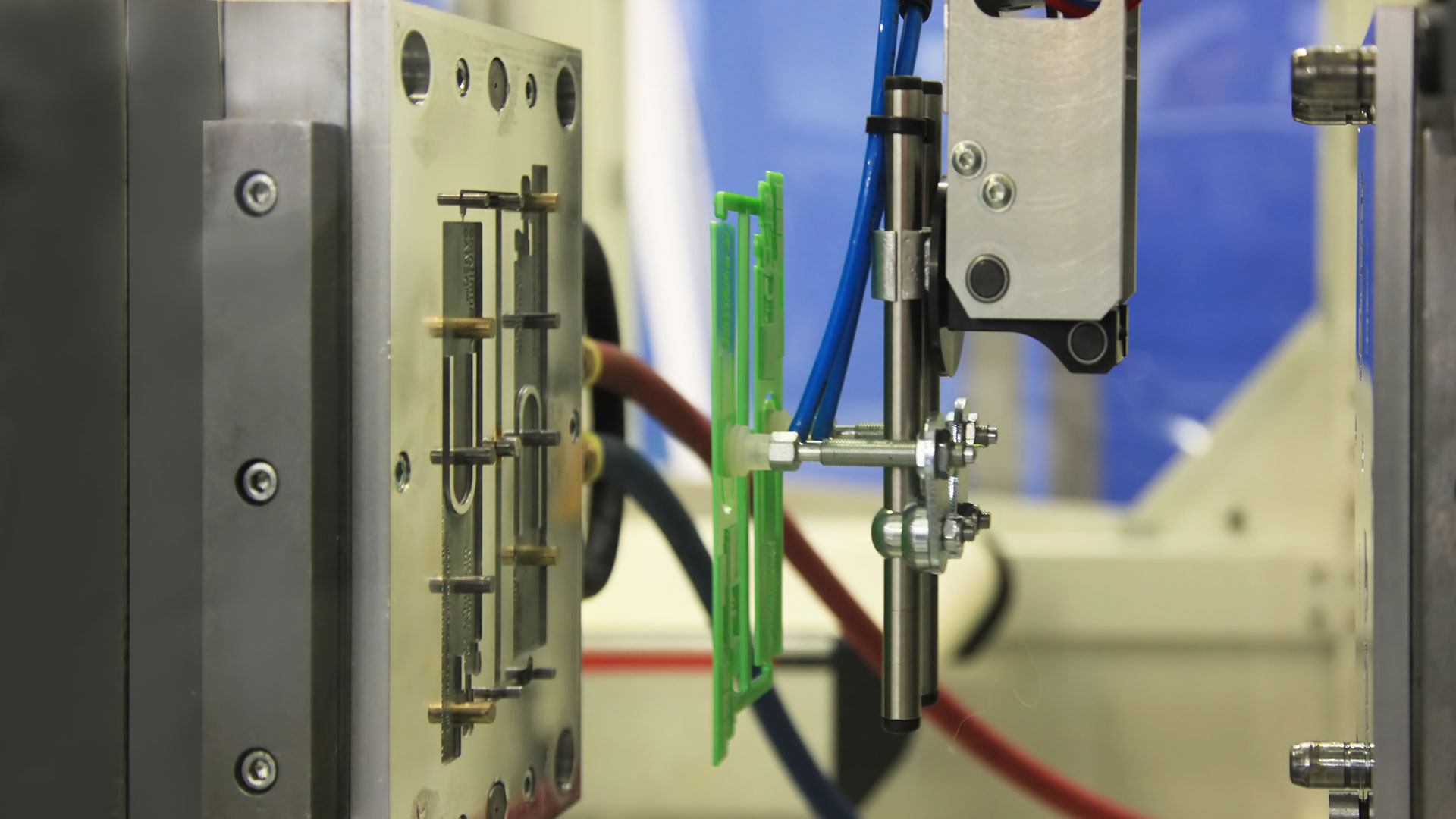

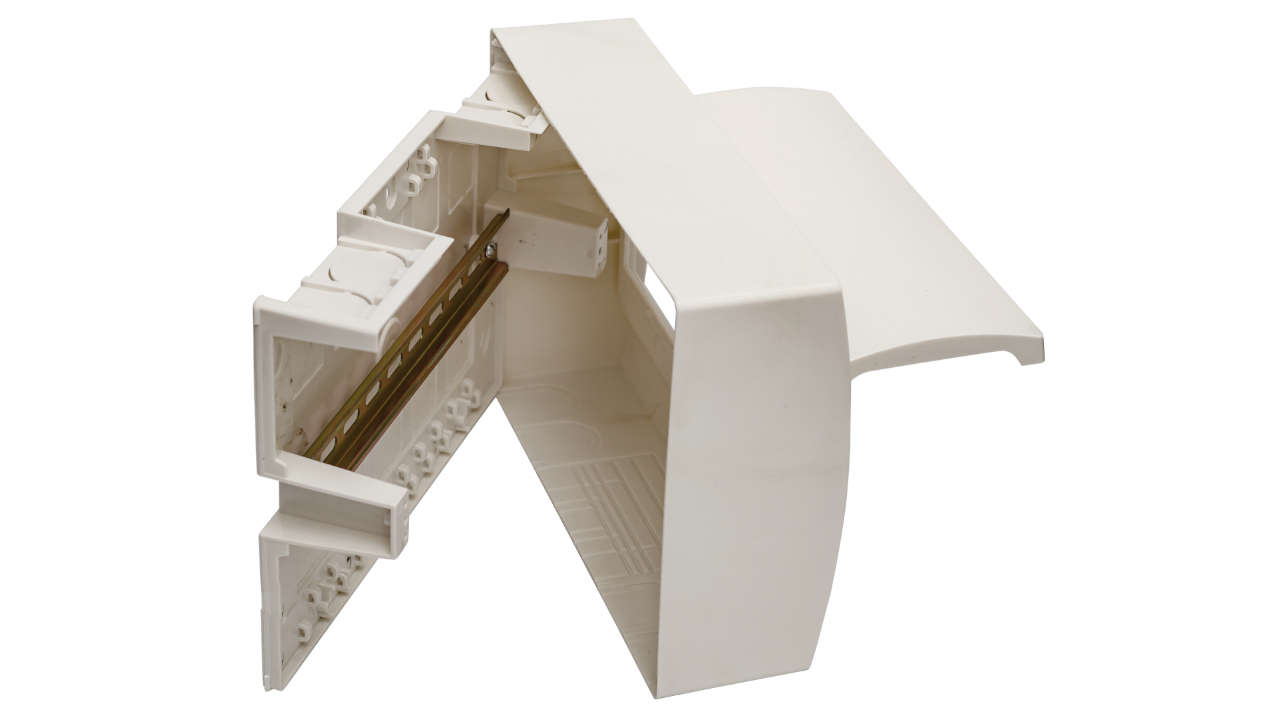

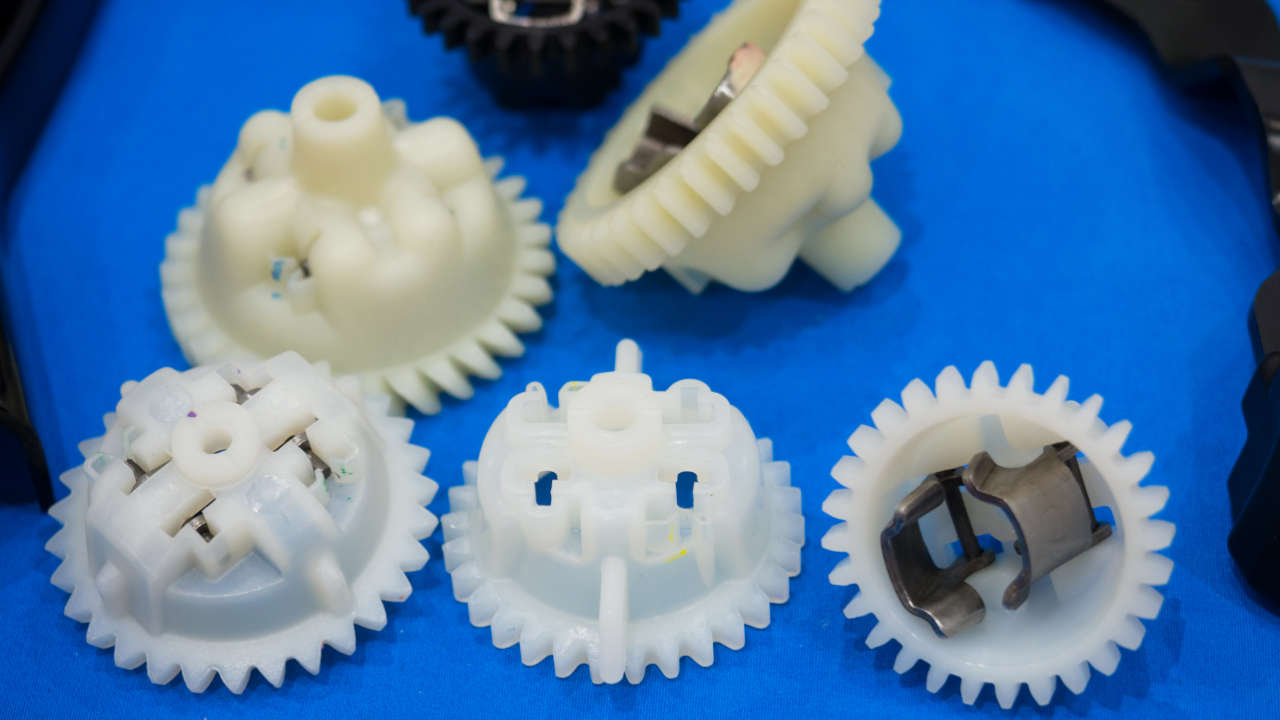

We mold precision plastic housings and overmolds using high-performance resins such as ABS, polycarbonate, nylon, and glass-filled blends tailored to meet the mechanical, thermal, and aesthetic demands of your application. These custom-molded components can be designed to interface seamlessly with your PCBAs, connectors, and mechanical sub-assemblies, streamlining the final build process.

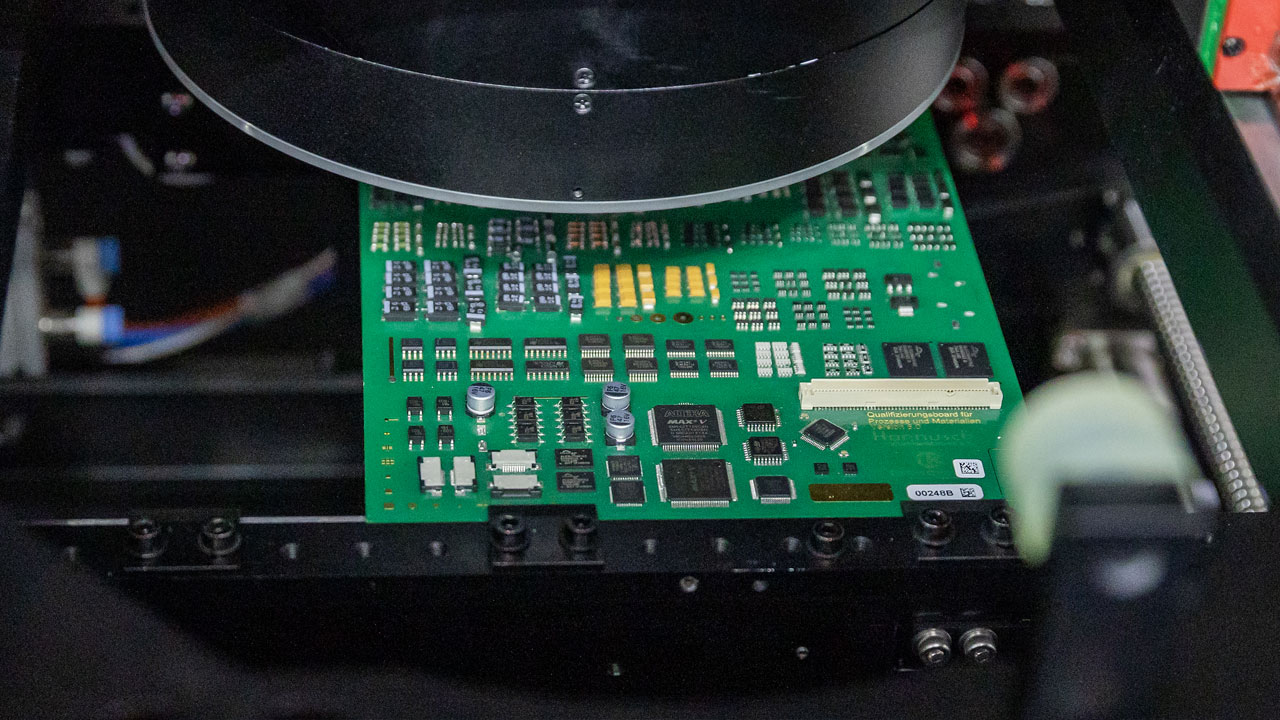

To protect internal circuitry from moisture, dust, vibration, and thermal extremes, we offer a range of coating and potting solutions. From selective conformal coating to full encapsulation, each process is optimized for adhesion, coverage, and process control, ensuring reliable performance in mission-critical environments.

Whether you’re building industrial controls or outdoor IoT devices, our integrated molding and coating services help reduce part counts, improve assembly efficiency, and safeguard your electronics every step of the way.