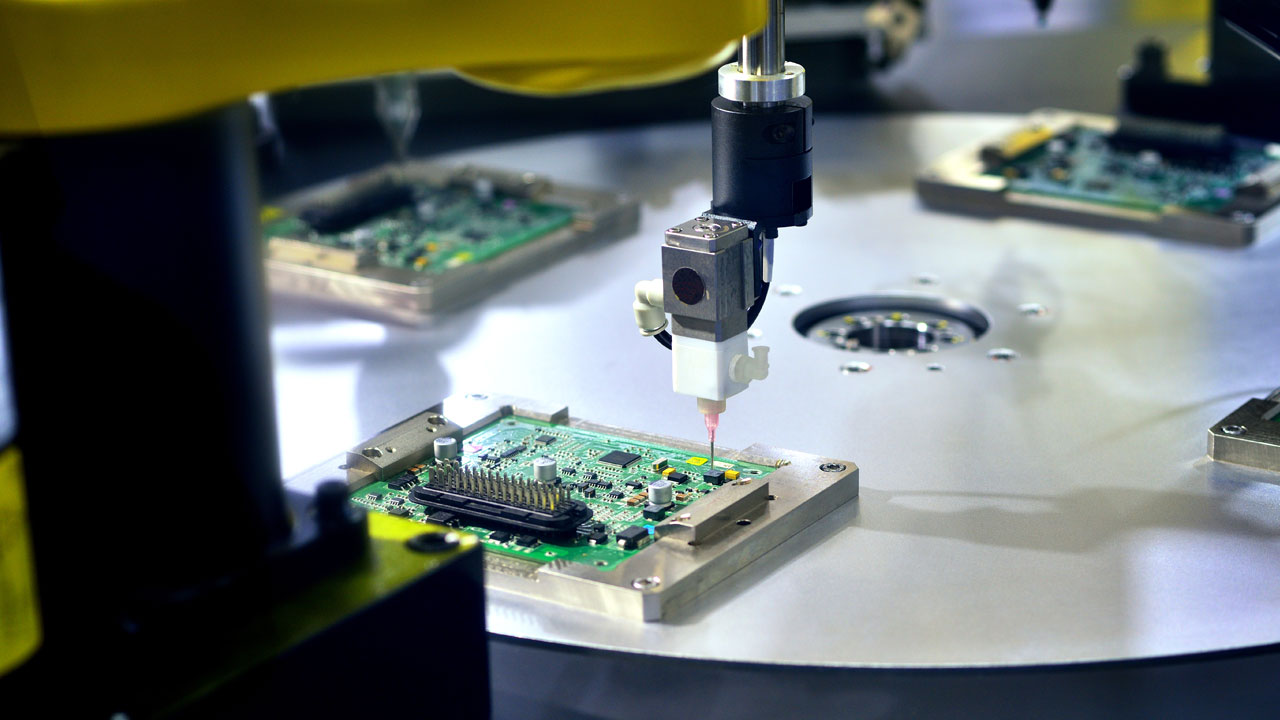

Turnkey PCBA project management streamlines what can otherwise be a complex and fragmented process. Instead of juggling multiple vendors, suppliers, and production stages, you get a single, reliable EMS partner to manage every detail, from sourcing and fabrication to assembly, testing, and delivery.

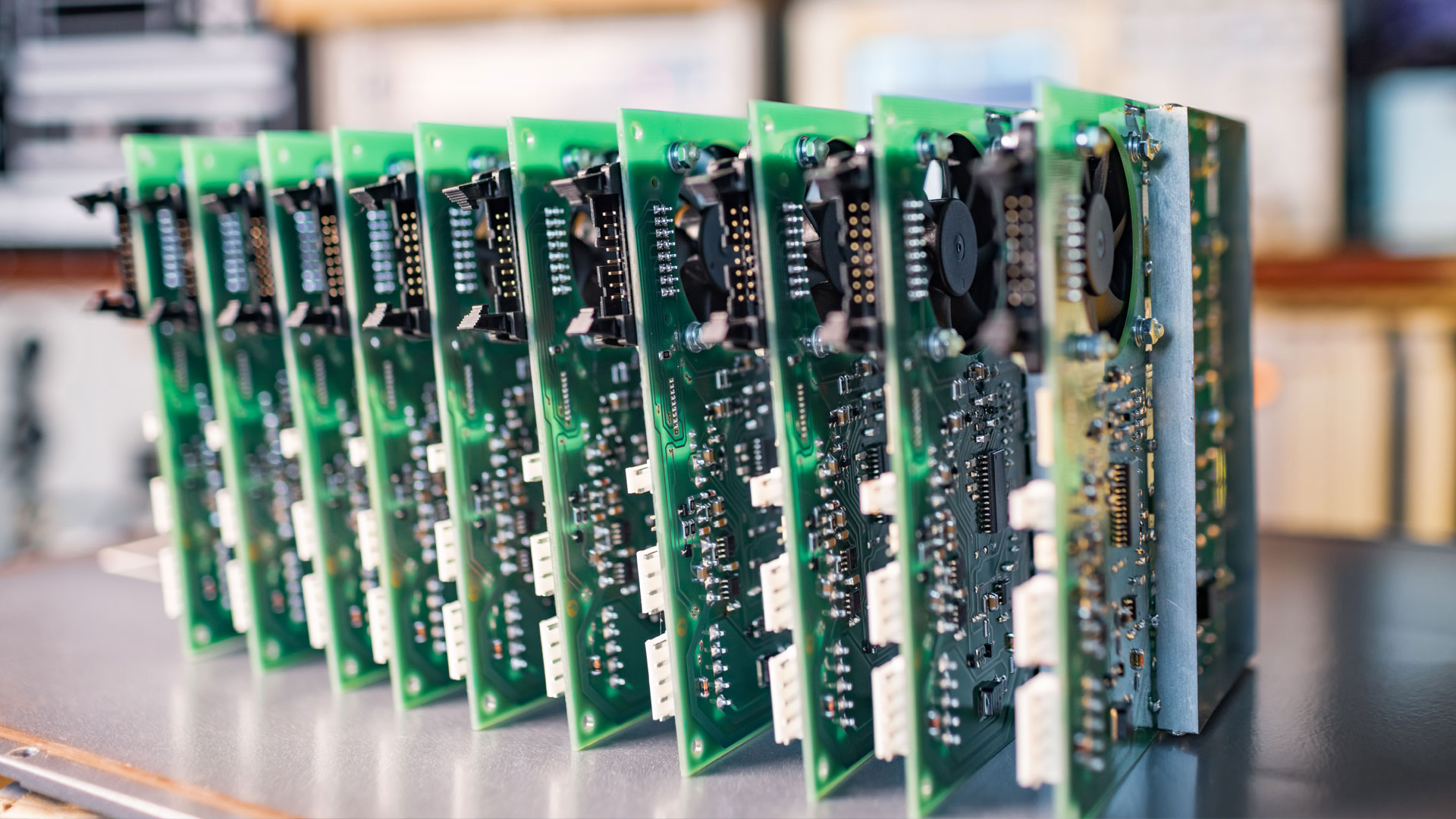

At Foxtronics EMS, our service is never off the shelf; it is tailored to your product, your timeline, and your industry. We take full ownership of your PCB assembly project, managing every aspect from component sourcing and PCB fabrication to assembly, inspection, and delivery. Our flexible turnkey PCBA solutions support a wide range of needs, whether you require rapid prototypes, high-mix low-volume runs, or full-scale production. The Foxtronics team partners with you early in the process to help optimize designs, select the right materials, and plan production with clarity and control.

With strong supplier networks, certified processes, and built-in traceability, we ensure every printed circuit board meets your technical, quality, and regulatory requirements. Whether you are scaling a new product, running high volume production, or managing high-mix batches, our turnkey model keeps the process efficient, predictable, and fully aligned with your goals.

This is a smarter approach to PCB assembly, delivering fewer risks, fewer surprises, and greater confidence at every step. From straightforward PCB assemblies to complete box builds, Foxtronics EMS makes turnkey truly turnkey so that you can focus on innovation instead of operations.