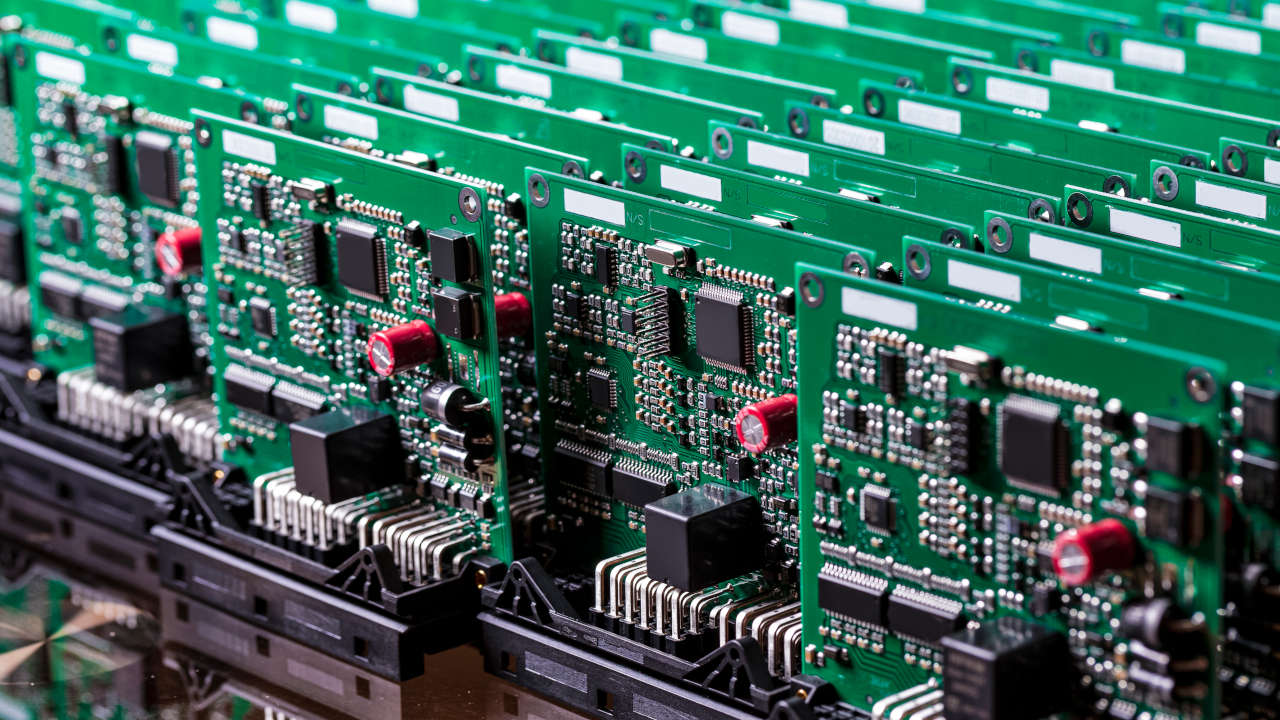

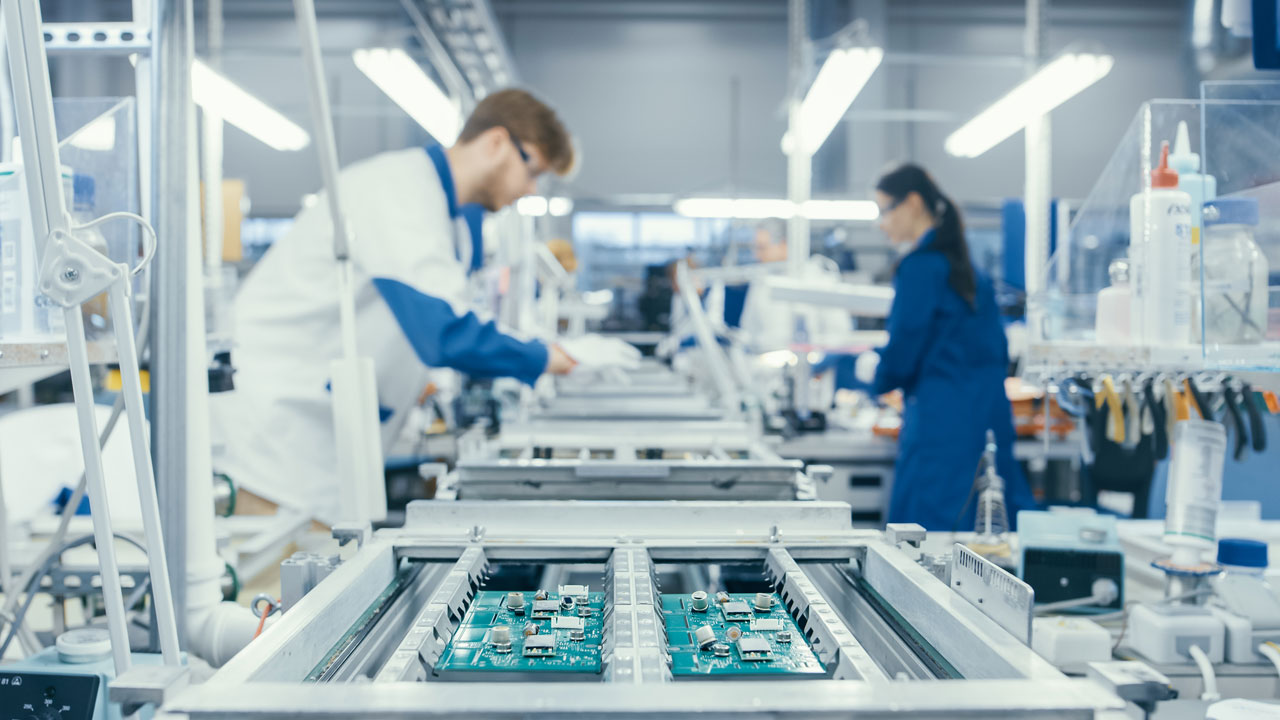

When it comes to high volume PCBA manufacturing, capacity alone isn’t enough. Achieving scale demands precision, reliability, and tight process control. Foxtronics EMS delivers robust, high volume PCB assembly services built for sustained, repeatable output at scale. Whether you’re launching a high-demand commercial product or manufacturing a critical industrial or medical device, we provide the infrastructure, process control, and quality systems to meet your volume goals without sacrificing speed or traceability.

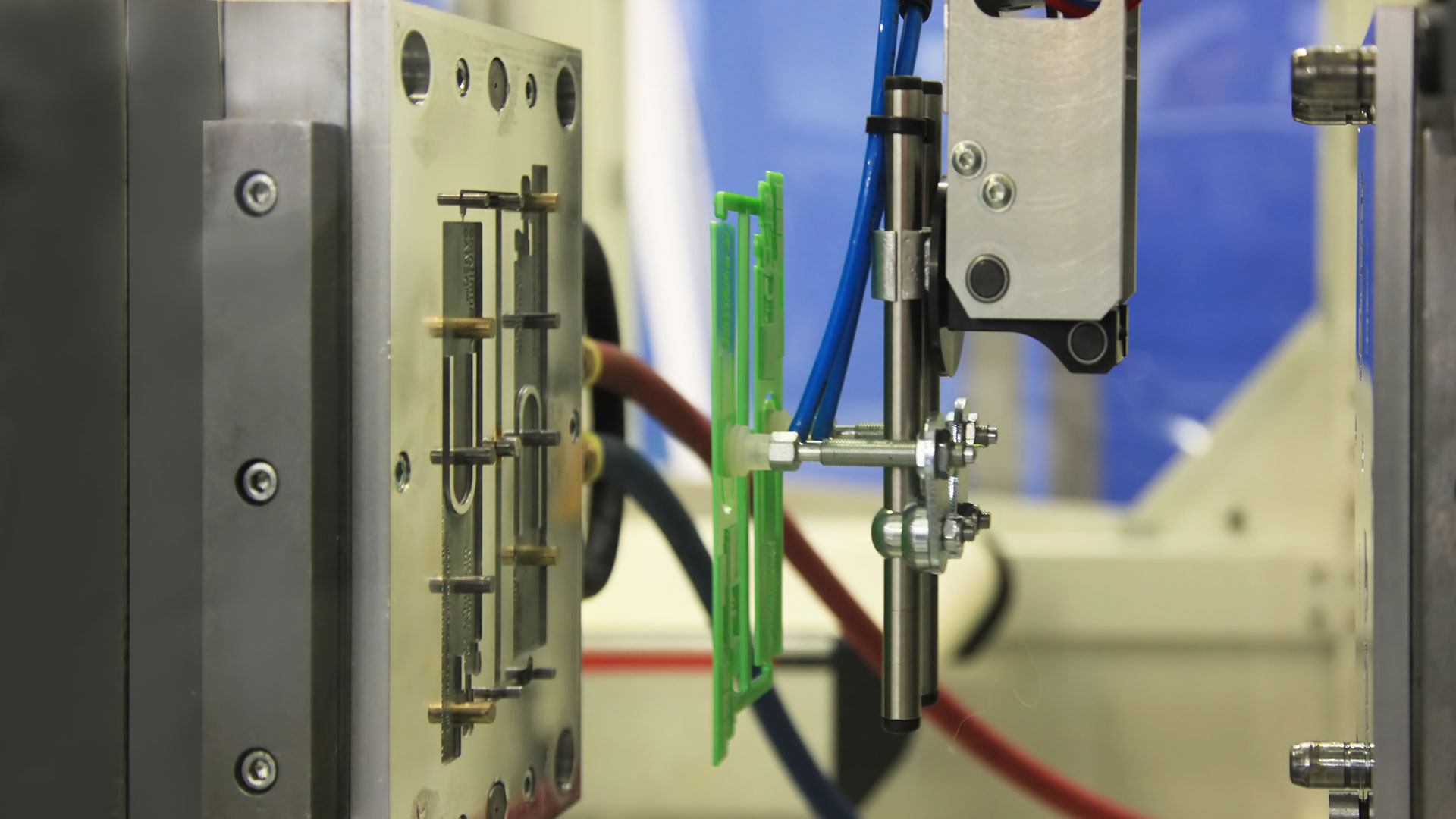

Our automated SMT lines, high-speed pick-and-place systems, and in-line testing platforms support complex assemblies and dense multi-layer PCBs with high throughput. Every process is engineered for lean execution, process discipline, and IPC-certified quality, ensuring every unit meets your exact specifications, regardless of quantity.

Beyond the production floor, we support the full product lifecycle with integrated services: strategic sourcing, logistics, packaging, and global fulfillment. Certified to ISO 9001, AS9100D, and ISO 13485 standards and equipped for IPC Class 2 and 3 production, our PCBA production facilities meet the highest requirements of regulated sectors. With Foxtronics EMS, high volume manufacturing becomes a strategic advantage, accelerating time to market and enabling sustainable growth.