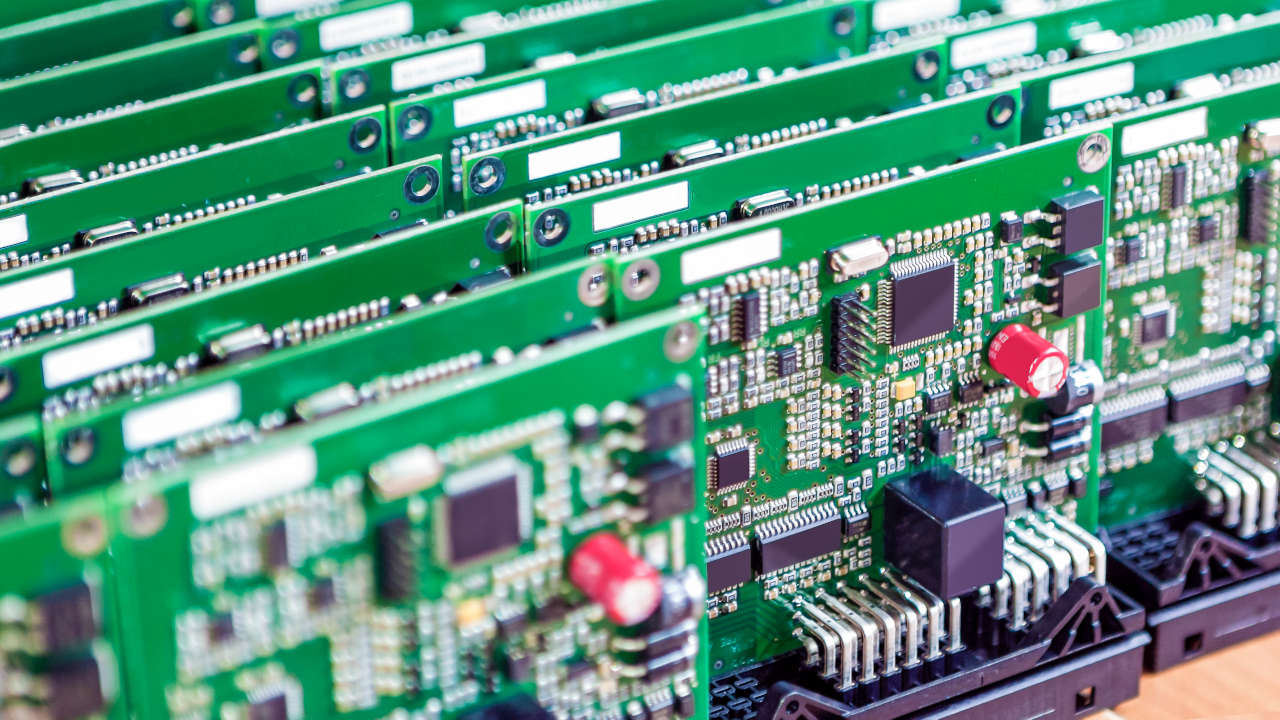

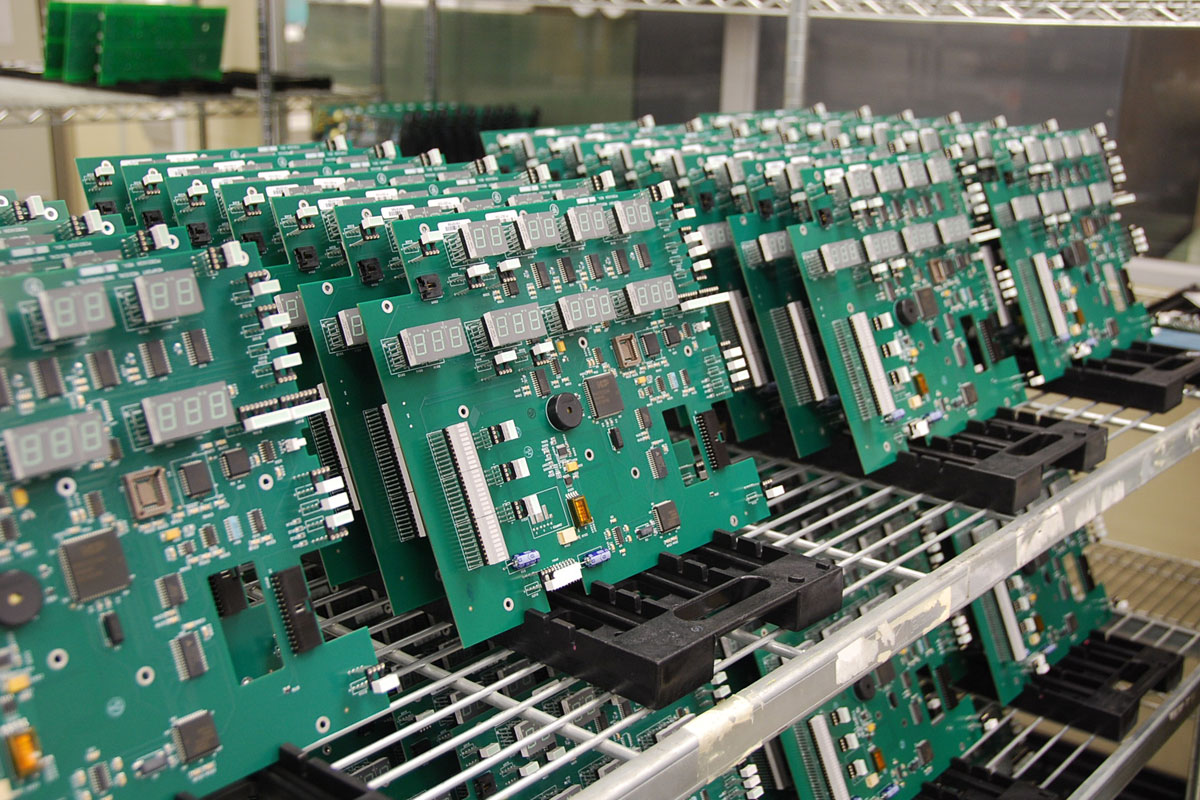

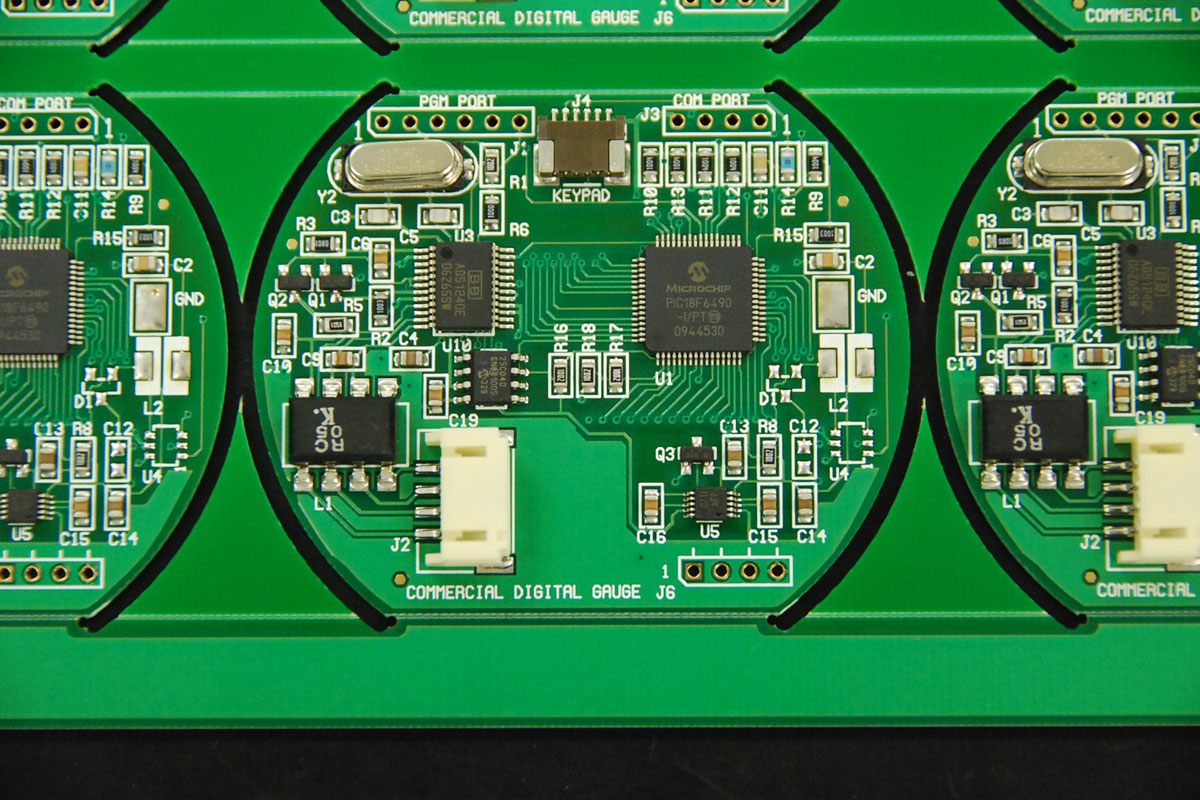

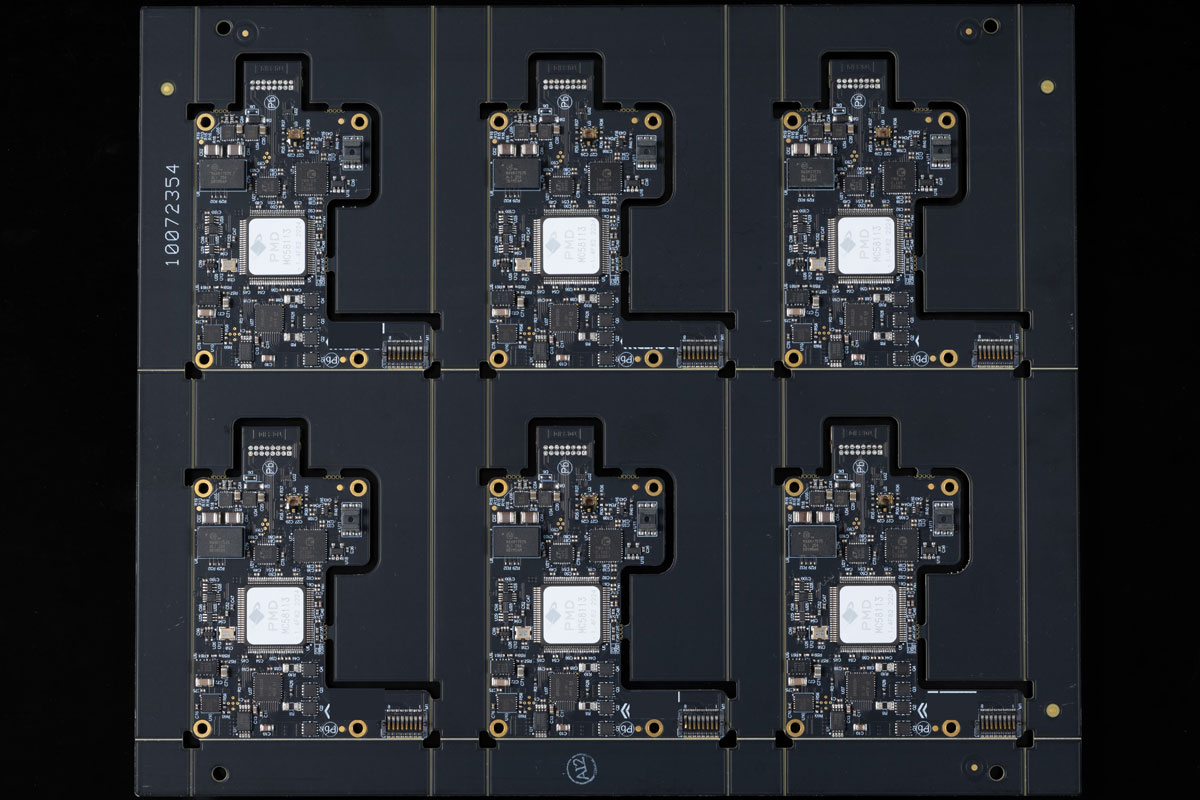

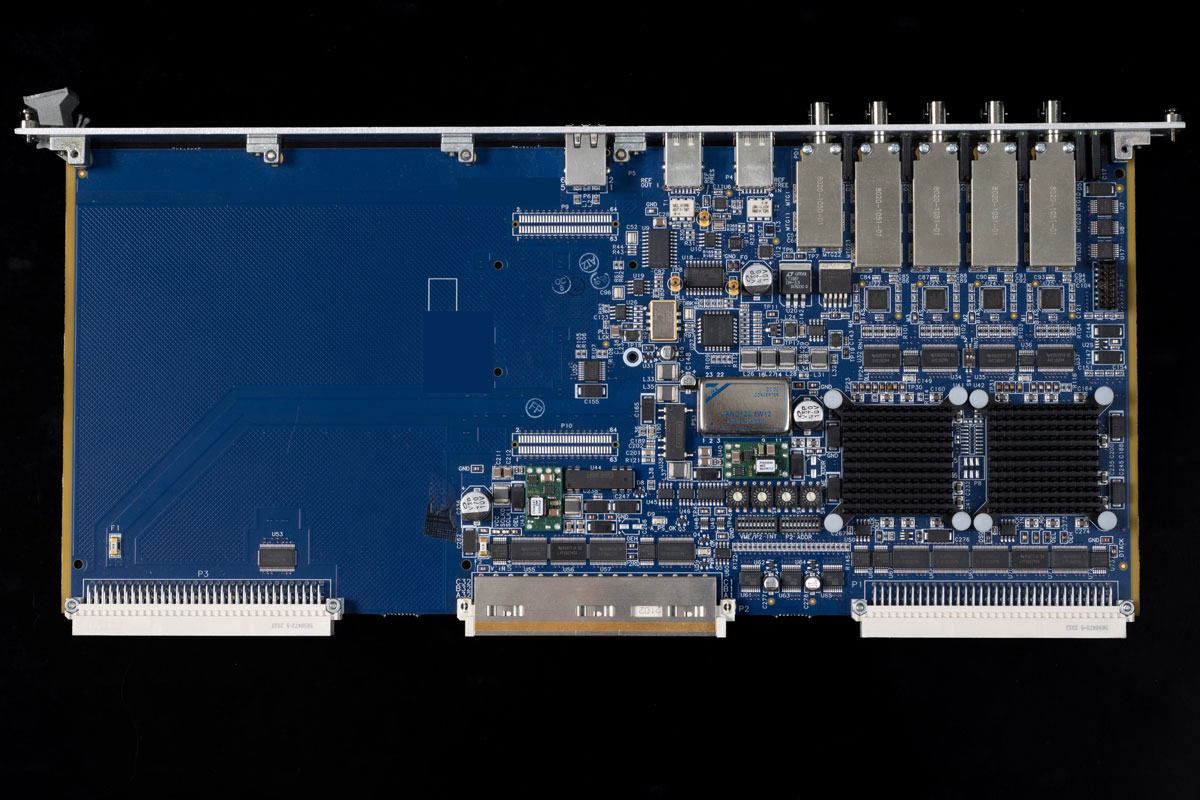

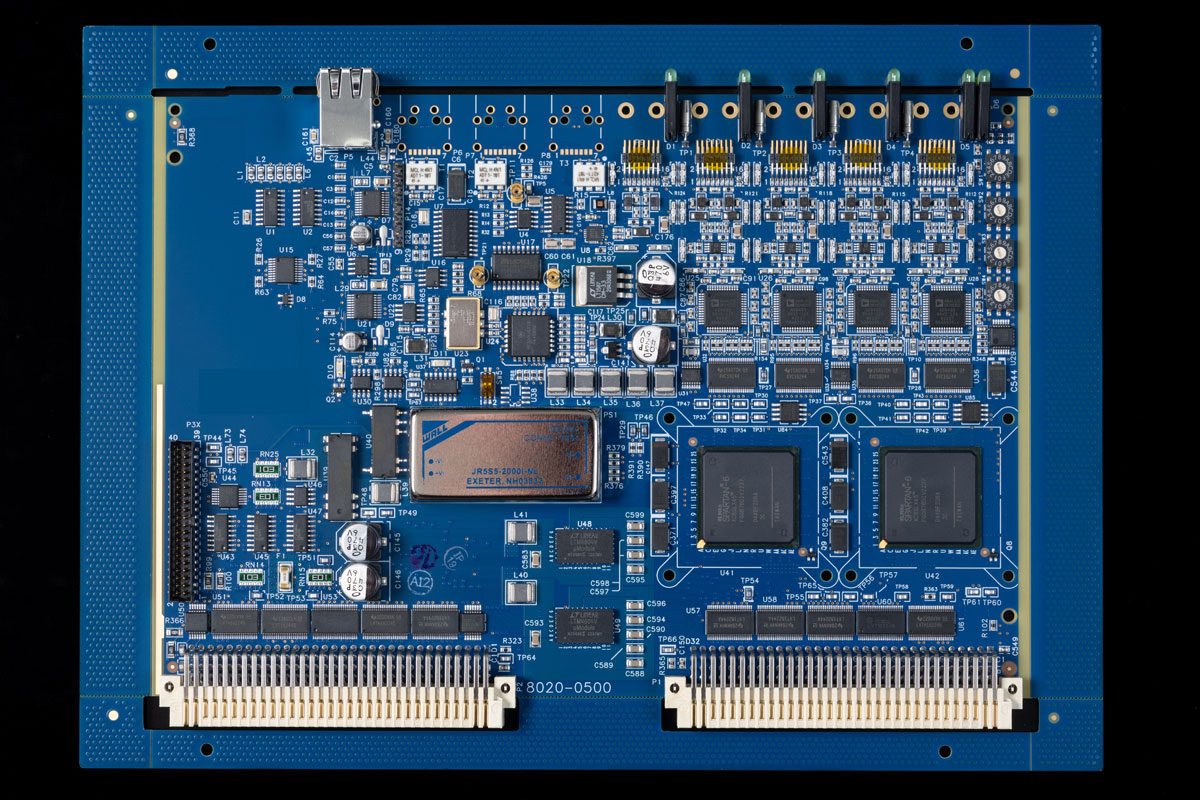

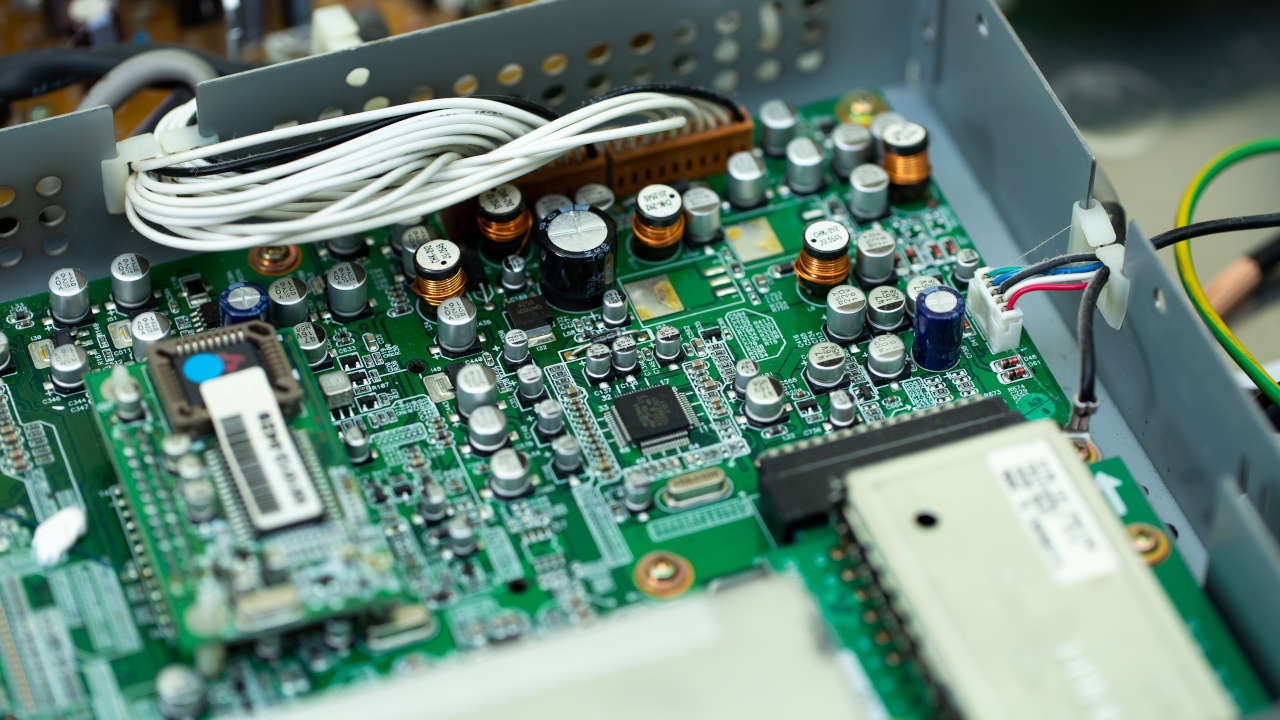

Surface Mount Technology (SMT) is the backbone of modern electronics manufacturing, enabling compact, high-performance reliability across industries. At Foxtronics EMS, our SMT assembly services are designed to meet the demands of advanced applications where precision, throughput, and repeatability are critical.

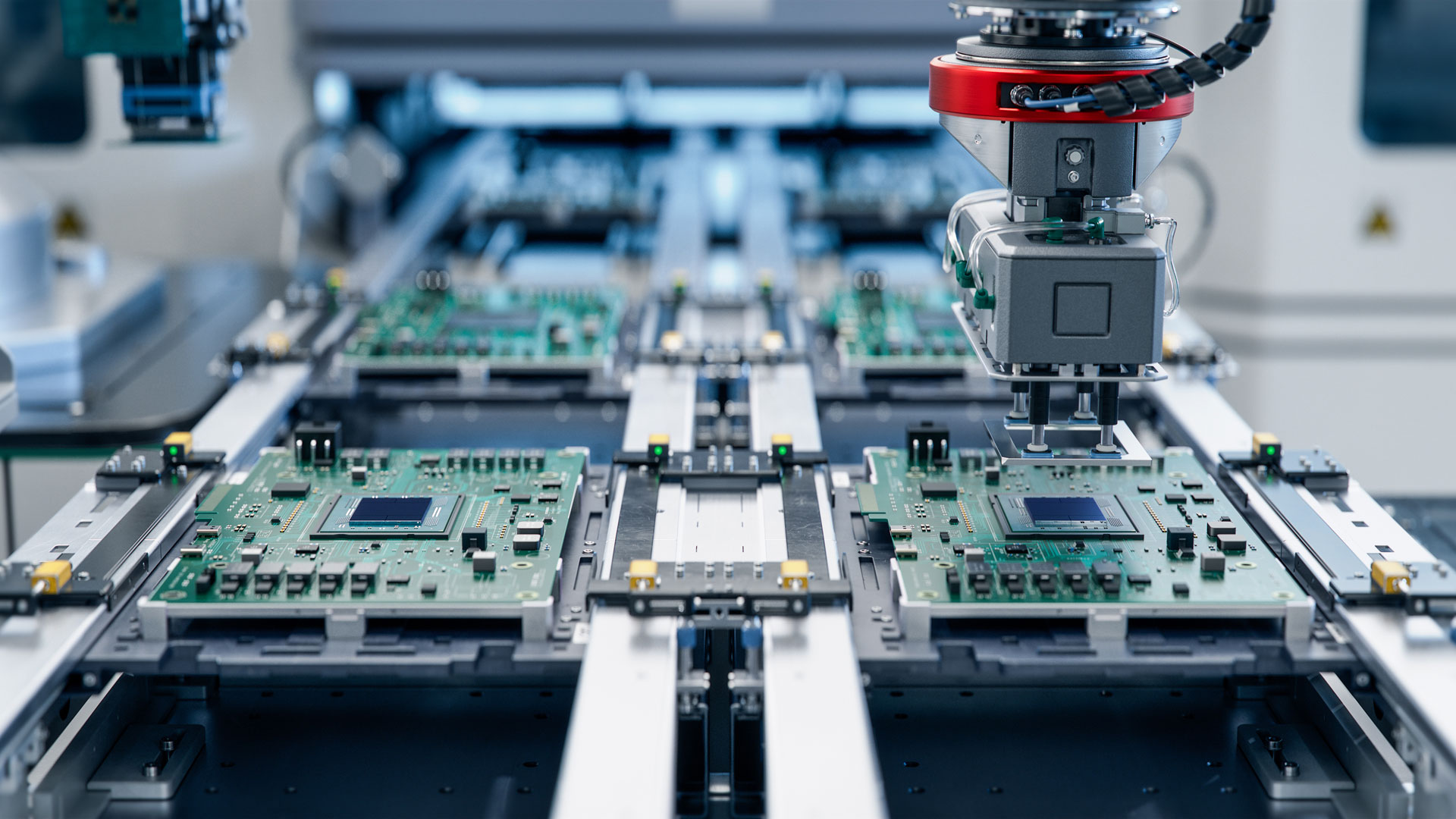

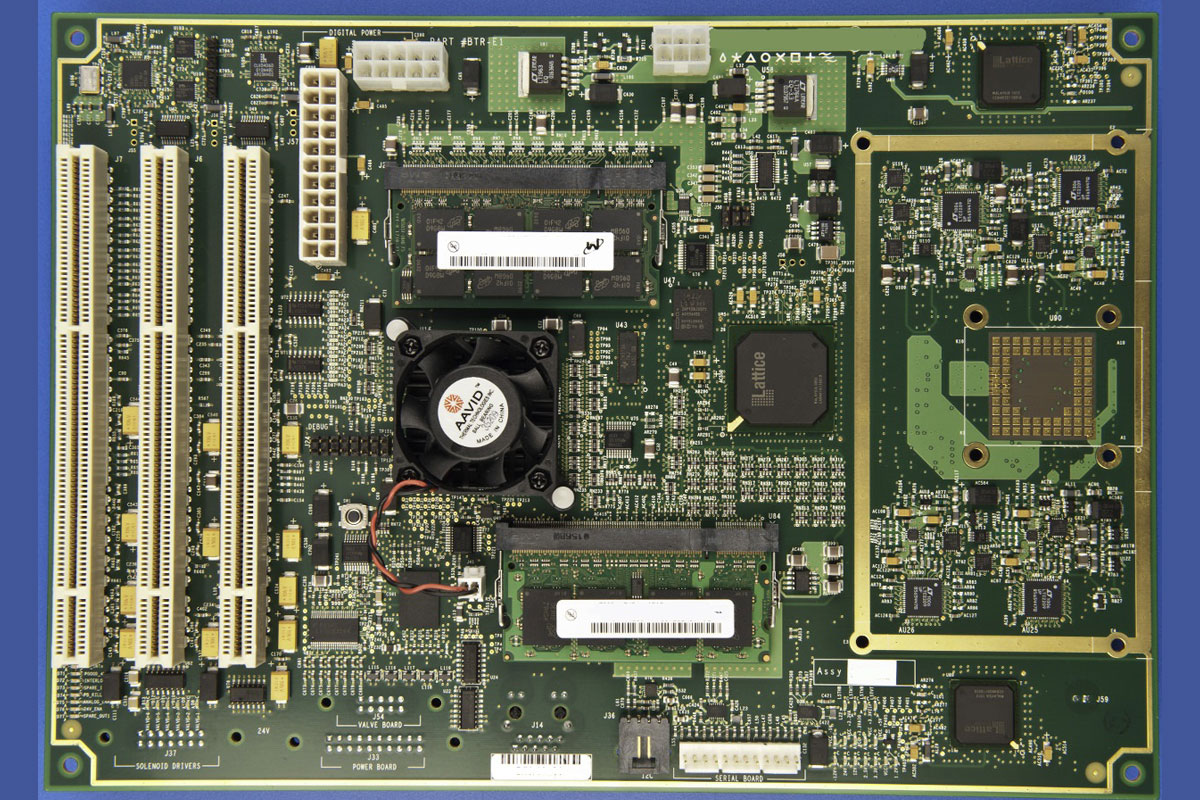

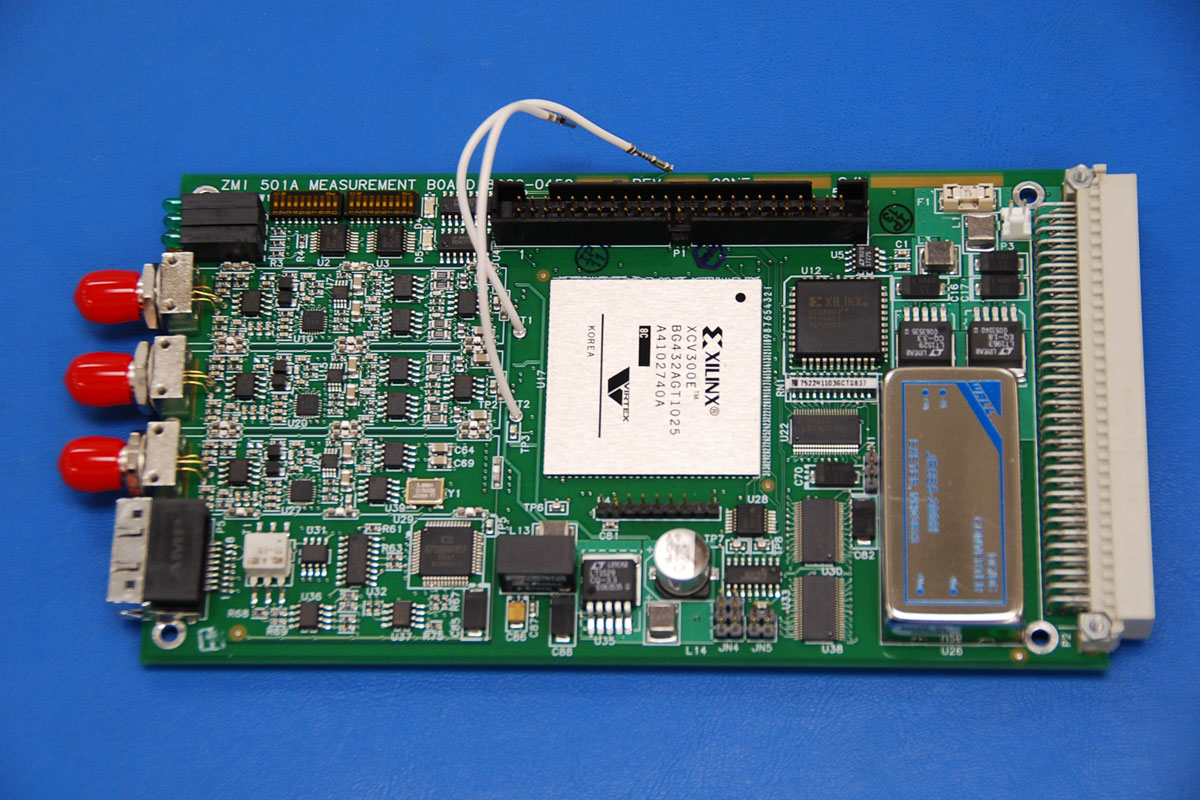

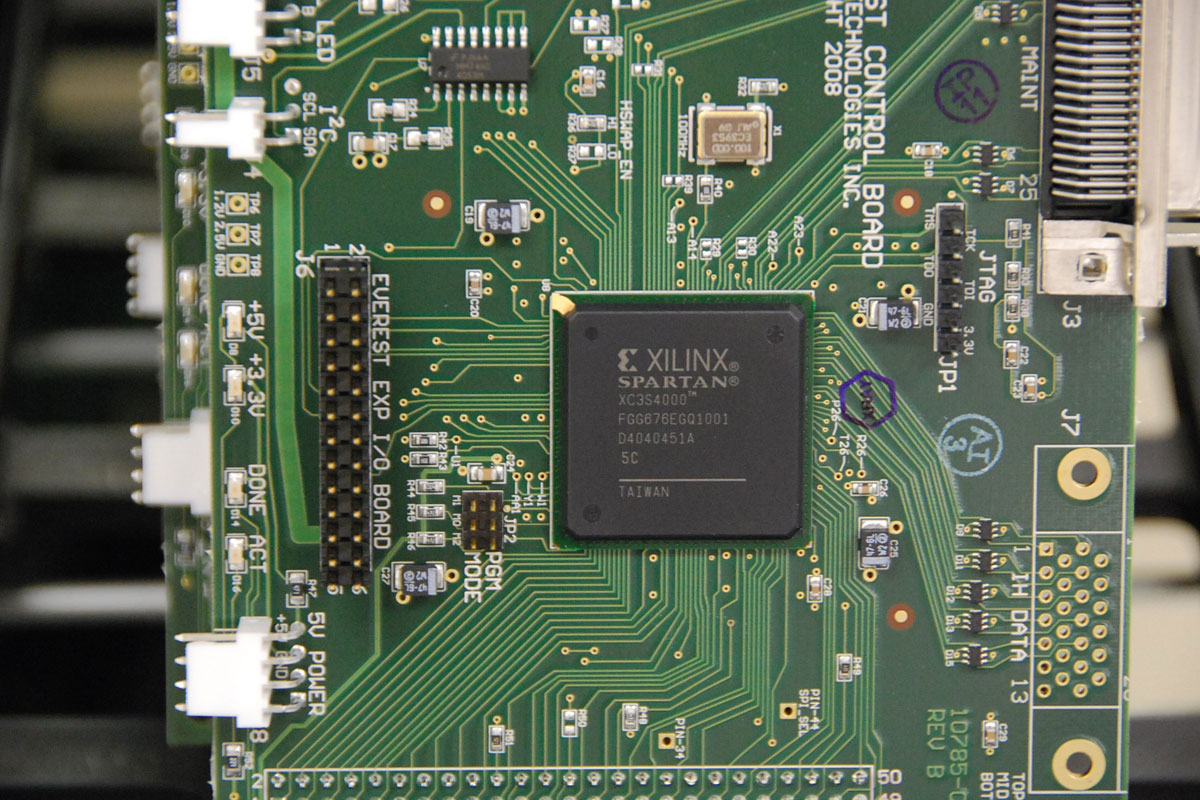

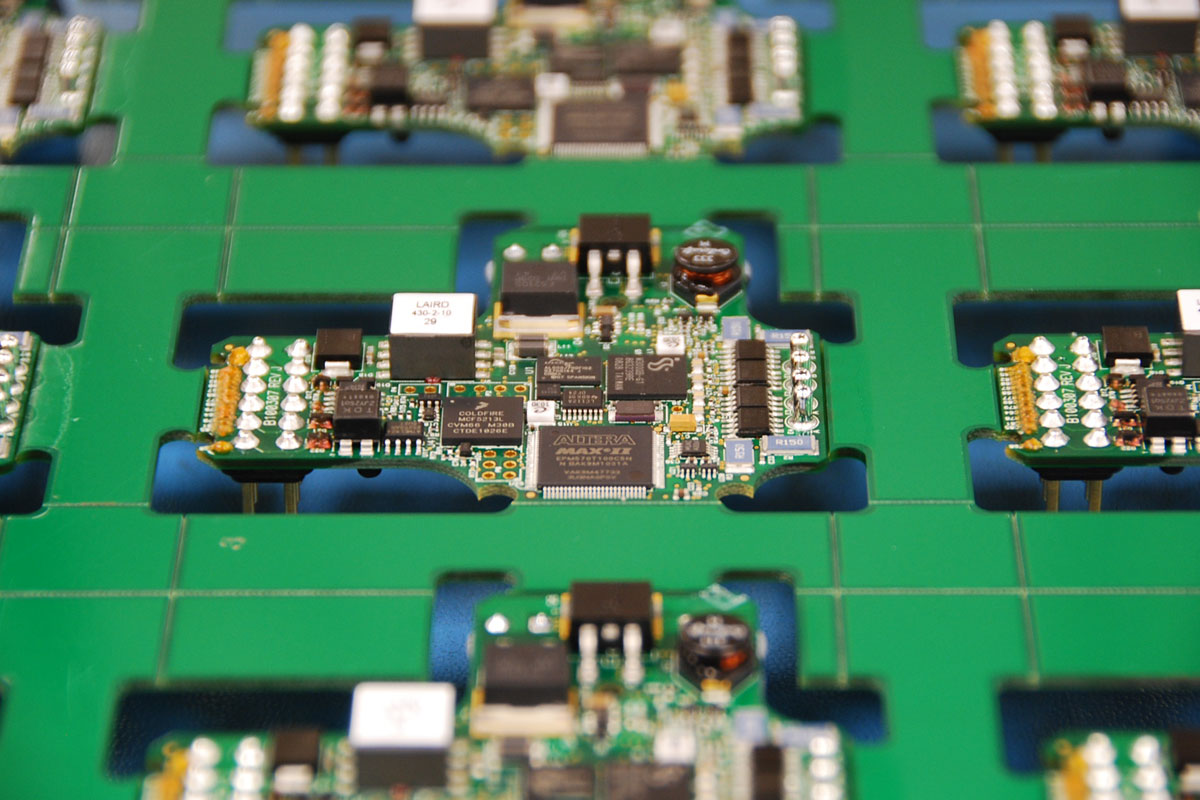

Our U.S.-based PCBA manufacturing facilities are equipped with state-of-the-art SMT assembly lines and offer complete solutions from rapid prototyping and New Product Introduction (NPI) to high-mix, high-volume production. Each line features advanced pick and place systems, inline optical inspection, reflow ovens, and comprehensive traceability to ensure consistent quality in every build. Our deep process expertise, strict quality standards, and IPC‑certified workmanship are strengthened by ongoing SMT assembly process optimization and quality control, giving customers confidence that every build meets the tightest tolerances and demanding industry requirements.

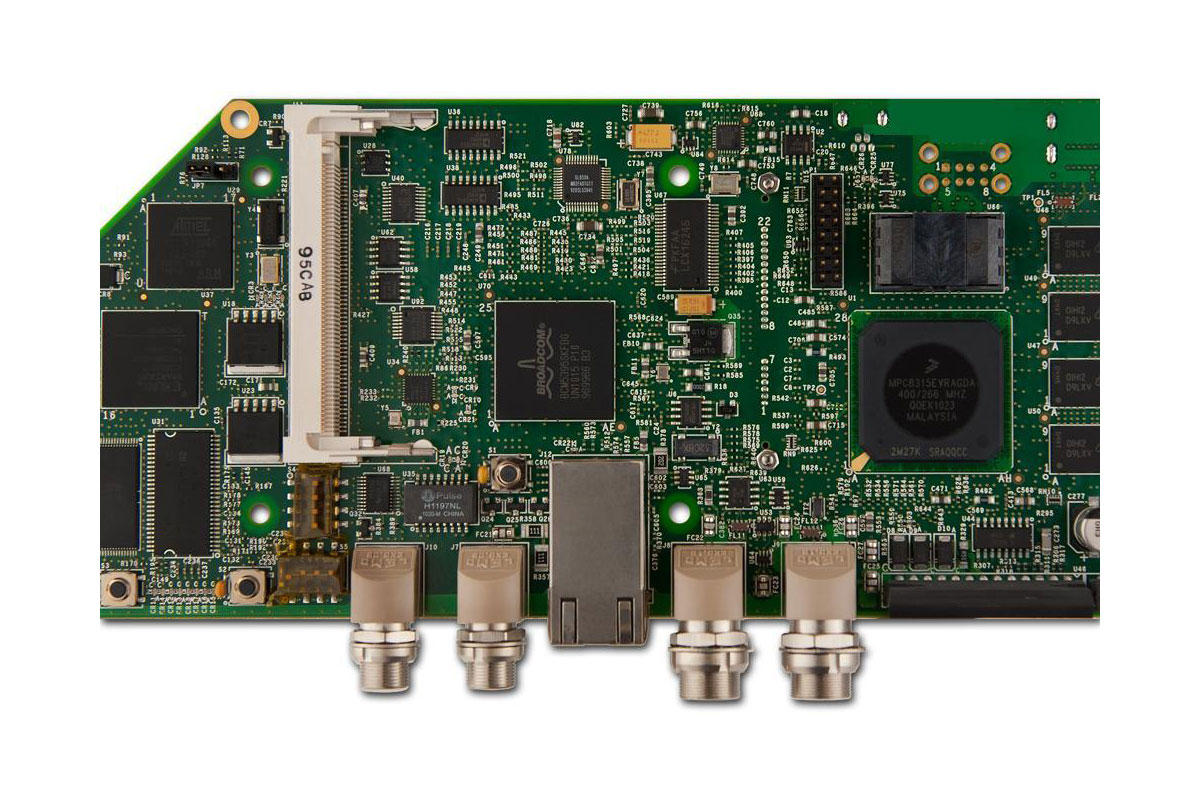

Whether you are developing mission-critical aerospace electronics or next-generation medical devices, Foxtronics EMS delivers scalable SMT PCB assembly solutions that support your product goals, compliance needs, and time to market objectives.