In today’s fast-moving electronics market, reliable contract manufacturing isn’t just a service—it’s a strategic advantage. Whether you’re launching a new product, scaling production, or reshoring operations, having the right EMS partner ensures speed and quality without compromise. That’s where Foxtronics EMS delivers, combining consistency, scalability, and responsiveness across every stage of the process.

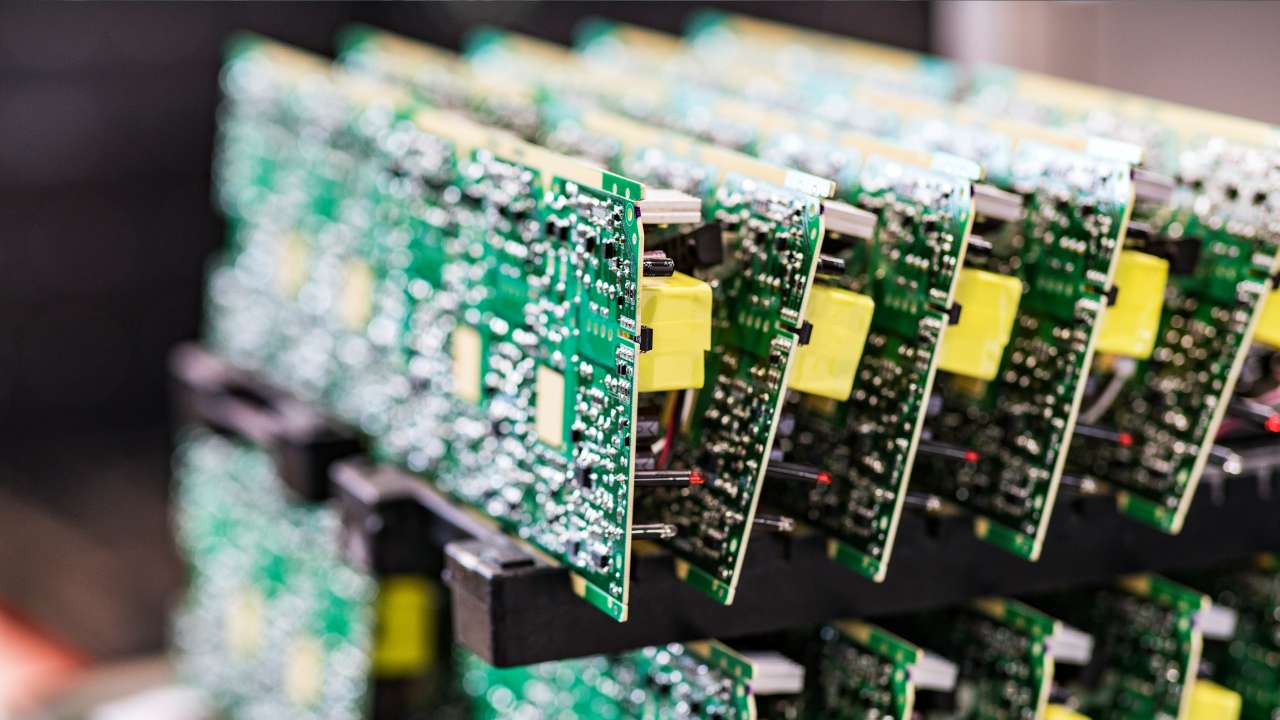

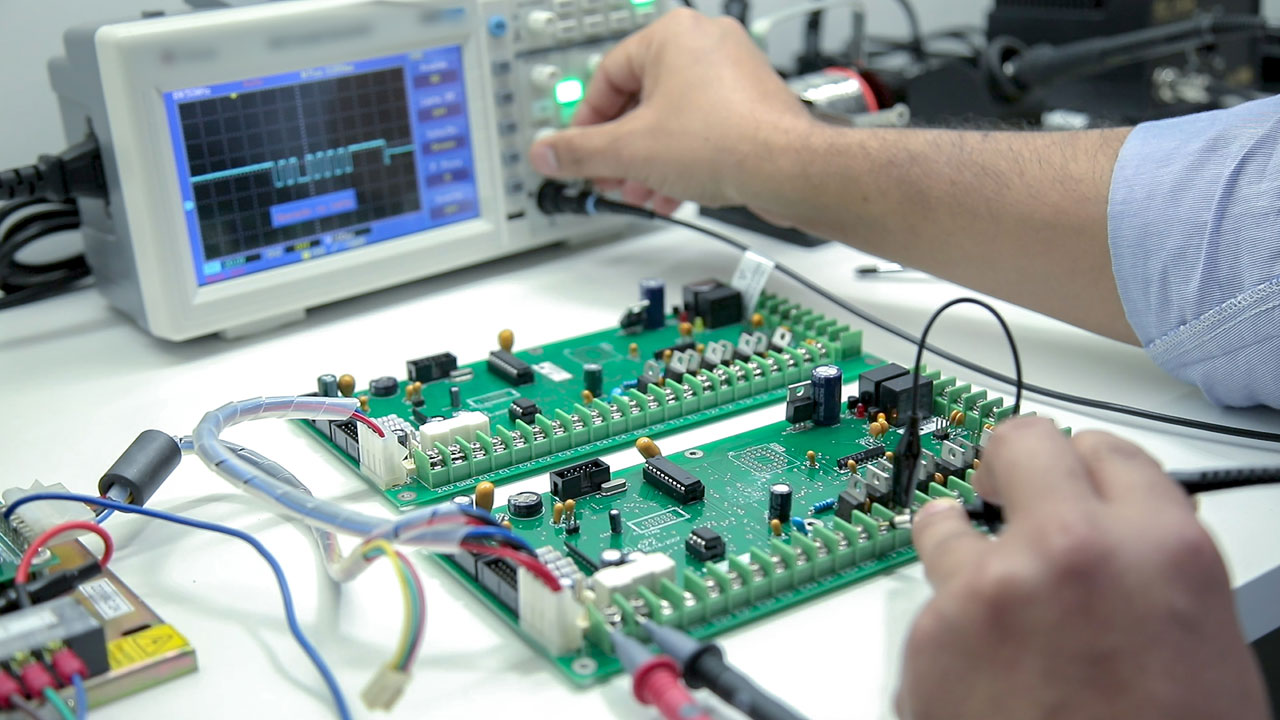

Our approach is built on collaboration, accountability, and disciplined processes. We work as an extension of your team, supporting you from design validation and component sourcing through assembly, testing, and fulfillment. Our PCB assembly manufacturing facilities handle both high-mix low-volume and high volume production, with flexible engagement models that scale to your needs. Whether producing a legacy industrial system or a next-generation medical device, we deliver board-level assemblies with a focus on reliability, traceability, and compliance.

Our capabilities include surface mount (SMT) and through-hole assembly, functional testing, conformal coating, and full box build, all supported by close coordination among engineering, supply chain, and production. To manage complexity, we rely on defined workflows, robust documentation, and real-time production oversight. Whether managing multiple SKUs or a single flagship product, we ensure consistency through repeatable processes and strict quality control.

What sets Foxtronics EMS apart is not just its technical capacity, but also the ability to align people, systems, and strategy under one roof. We treat every program as a true partnership, applying lean principles, scalable systems, and operational transparency to ensure quality and continuity across the entire product lifecycle.