Bringing a product from concept to market-ready form is rarely straightforward. Design decisions made early in development have a lasting impact on manufacturability, cost, quality, and performance. That’s why Foxtronics EMS offers more than just production services; we become an extension of your engineering team from day one.

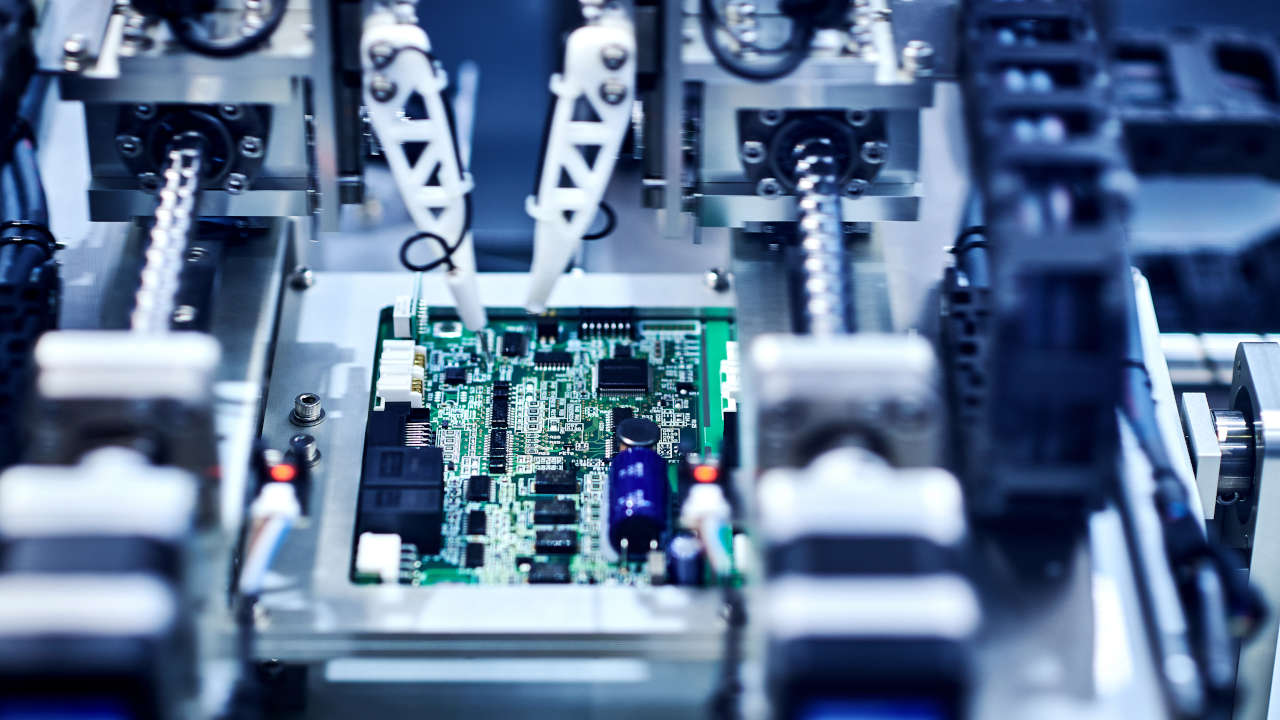

Our Design & Engineering services focus on minimizing risk, reducing time to market, and optimizing your product for real-world manufacturing conditions. With expertise in Design for Manufacturability (DFM) and Design for Testability (DFT), we help refine your PCB designs to ensure they are production-ready without compromising functionality or reliability.

This early collaboration allows us to spot potential bottlenecks, material challenges, and PCB assembly complexities before they turn into costly problems. Whether you need guidance for a prototype, support during New Product Introduction (NPI), or value engineering to reduce costs in high volume production, our team is equipped to guide you through every technical decision.

Every project benefits from our structured design review process, where electrical, mechanical, and production experts work together to ensure smooth downstream execution. The result? Smarter PCB designs, better yields, and fewer late-stage surprises. By integrating closely with your product development efforts, Foxtronics EMS empowers you to innovate with confidence, knowing your design is backed by manufacturing insight and engineering discipline.