PCB Assembly for Industrial & Automation

Reliable PCB assembly and electronic system integration for industrial automation, robotics, and control systems — designed for uptime, durability, and long service life in demanding environments.

Every production line, sensor hub, and automated control system depends on electronics that can survive long duty cycles and harsh operating conditions. From motor drives to PLC modules and robotic subassemblies, Foxtronics EMS builds industrial and automation PCB assemblies for electronic systems that power the modern factory floor — and keep it running.

We serve OEMs across industrial automation, motion control, energy management, and connected manufacturing systems. Our engineers understand the challenges of vibration, temperature extremes, EMI exposure, and electrical stress that define industrial environments. Each design is validated for durability and verified under controlled manufacturing processes to ensure repeatable, stable performance.

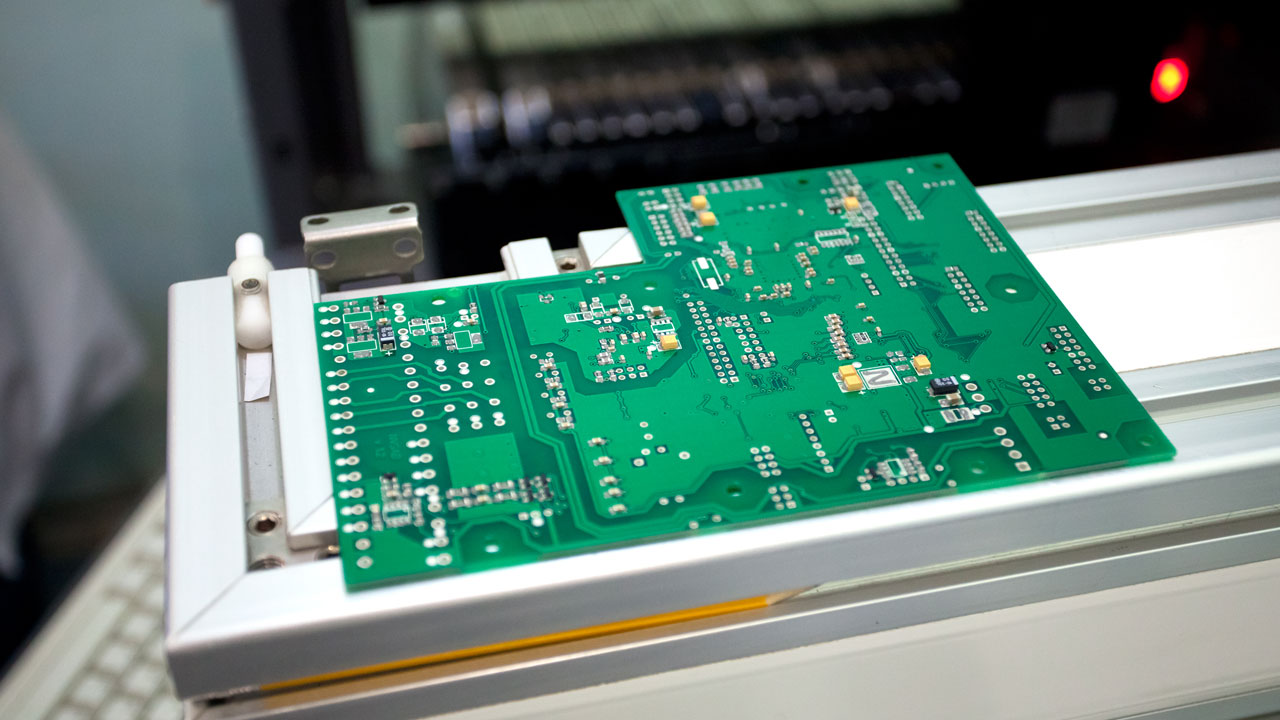

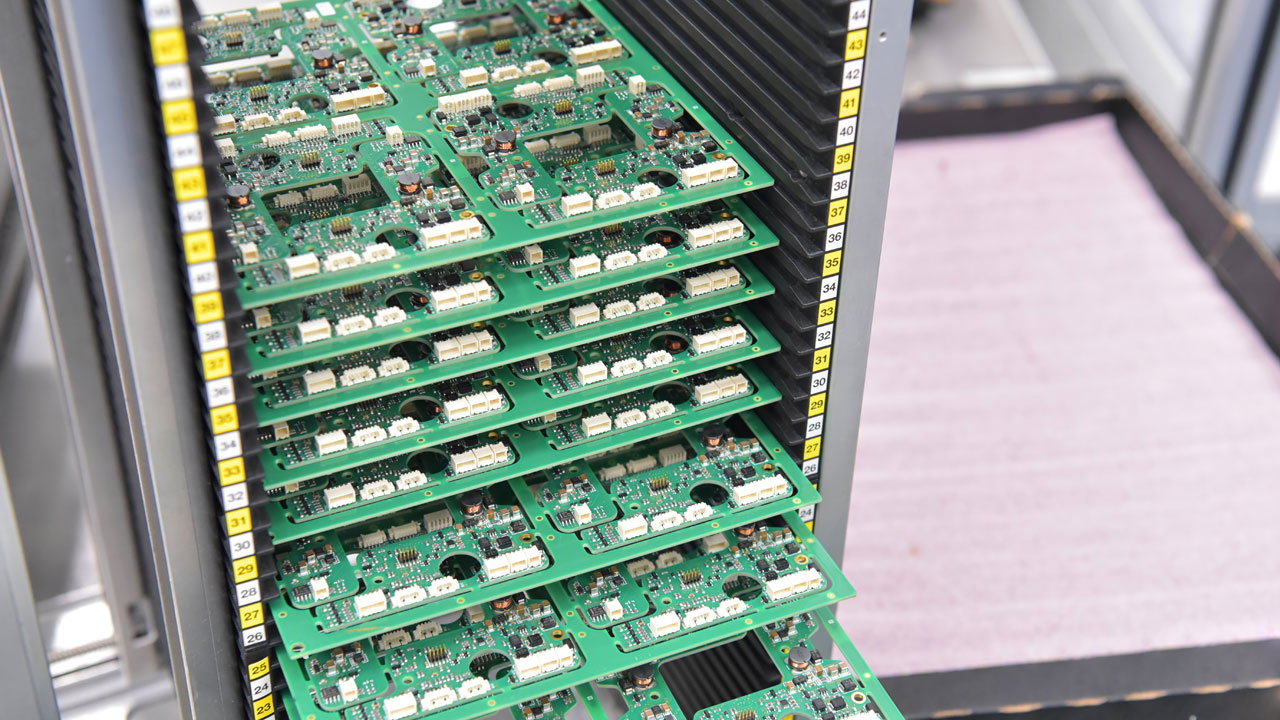

Our certified facilities support a wide range of PCB assembly production needs from pilot runs and high-mix, low-volume PCB assemblies to sustained, high-volume builds. We combine ISO 9001 and IPC Class 3 standards with lean manufacturing principles to deliver cost efficiency without compromising reliability. Through early engineering collaboration, design-for-manufacturability (DFM) review, and robust supply-chain planning, we help industrial OEMs minimize downtime, extend product lifecycles, and ensure continuity even when parts become scarce.

We believe that industrial reliability is built through deliberate efforts such as process discipline, material control, and experience. That’s exactly what Foxtronics EMS delivers through reliable electronics manufacturing for Industrial & Automation applications.

Industrial systems rarely rest, and neither can their electronics. Every relay, controller, or sensor interface has to function reliably across temperature swings, vibration, and electrical noise while maintaining tight performance tolerances.

Foxtronics EMS designs its PCB assembly processes around that reality. From conformal coating and thermal management to EMI shielding and mechanical ruggedization, each step ensures your electronic assemblies withstand operational stress. We perform environmental testing, functional validation, and long-term reliability checks to confirm consistent performance under load.

Our documentation and traceability standards give you complete visibility into materials, lot history, and test results, reducing downtime, simplifying maintenance, and protecting product integrity. For Industrial & Automation OEMs managing complex equipment fleets or field service programs, this level of documentation translates directly into lower total cost of ownership and longer equipment life.

From high-mix, low-volume controllers to scalable robotics and automation platforms, Foxtronics EMS provides end-to-end assembly, testing, and integration designed for uptime and long-term dependability.

Built for uptime and durability — coated, tested, and traceable assemblies ready for the plant floor. Each unit undergoes rigorous environmental and electrical validation to ensure consistent performance in demanding industrial conditions.

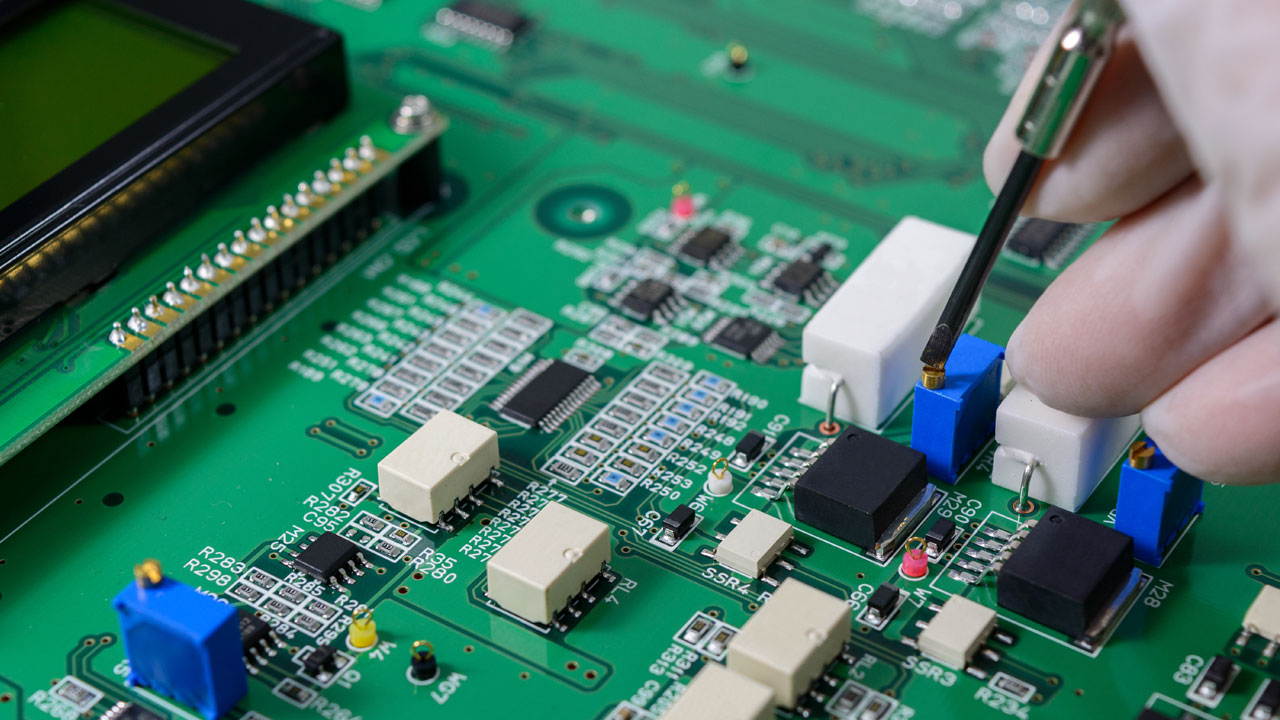

High-performance Surface Mount (SMT) and through-hole PCB assembly for control systems, motor drives, PLC I/O modules, HMIs, and power distribution boards. Each PCB assembly is built to meet IPC Class 2 or Class 3 standards and validated for mechanical and thermal endurance. We use selective soldering, X-ray inspection, and automated optical inspection (AOI) to ensure consistent joint integrity across every build.

Complete enclosure builds and industrial control panel integration, including harnessing, wiring, labeling, and full functional verification. We also provide configuration, burn-in testing, and documentation for plug-and-play field deployment.

Protection against moisture, dust, and chemical exposure using selective conformal coating and potting processes. Our coatings meet IPC-CC-830 and UL94 standards for insulation and flame resistance, extending the service life of equipment operating in aggressive industrial environments.

All assemblies undergo functional, in-circuit, and environmental testing to verify reliability in actual operating conditions. We perform temperature cycling, vibration testing, and high-voltage insulation checks to validate performance over the full range of expected conditions.

Foxtronics EMS provides component lifecycle monitoring, alternate sourcing, and last-time-buy strategies to protect OEMs from supply disruptions. Our supply chain management team proactively works to ensure material continuity and minimize redesigns due to obsolescence.

Manufacturing uptime is everything, and we treat it that way. Foxtronics EMS supports industrial and automation OEMs with robust engineering collaboration, stable processes, and traceable quality systems that prevent failures before they occur.

We know how to design for maintainability, validate for reliability, and document for compliance. Our partnership-driven approach ensures that your products not only perform under pressure but remain serviceable and scalable for years to come. When equipment failure is not an option, Foxtronics EMS helps keep your production running, one reliable board at a time.

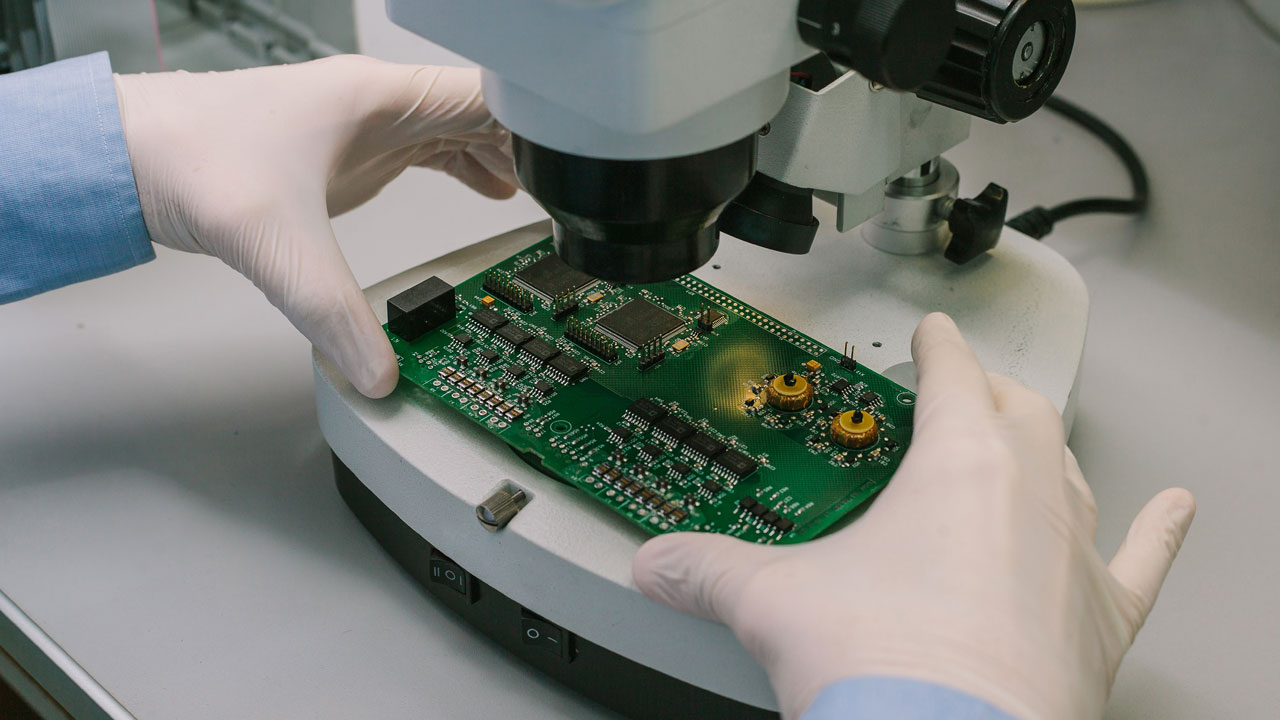

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Get answers to common questions about our industrial automation PCB assembly, turnkey solutions, and how we ensure durability, uptime, and long service life in demanding environments.

We build control boards, PLC I/O modules, robotics controllers, sensor interfaces, HMI systems, power modules, and automation sub-assemblies for a wide range of industrial applications.

We use conformal coating, mechanical reinforcement, and environmental testing — including vibration, humidity, and thermal cycling — to validate long-term performance.

Yes. Our engineering team reviews designs for manufacturability, test coverage, and component availability to ensure smooth production and faster time-to-market.

Absolutely. We provide lifecycle monitoring, approved alternates, and sourcing strategies to prevent material shortages and design interruptions.

We comply with ISO 9001 and IPC Class 2/3 workmanship standards and follow RoHS and REACH guidelines for materials and process control.