PCB Assembly for Emerging Technologies

Advanced EMS solutions for robotics, EVs, renewable energy, and smart connected devices, enabling innovation through design precision, scalability, and manufacturing excellence.

Technology advances quickly, and so do the expectations that come with it. From autonomous systems and electric vehicles to renewable energy and cutting-edge robotics, emerging markets need EMS partners who can keep up with innovation while maintaining reliability.

Foxtronics EMS provides the manufacturing foundation for breakthrough technologies. We work alongside product innovators, R&D teams, and tech startups to translate prototypes into scalable, production-ready PCB assemblies that meet strict performance and regulatory standards.

Our experience spans power electronics, sensor networks, IoT controllers, and high-speed processing systems. By combining precision PCB assembly, advanced testing, and global supply chain control, we help future-focused companies move from proof of concept to market faster.

Every build is supported by design-for-manufacturability (DFM), traceability, and quality control that scale seamlessly as your technology advances from prototype to production.

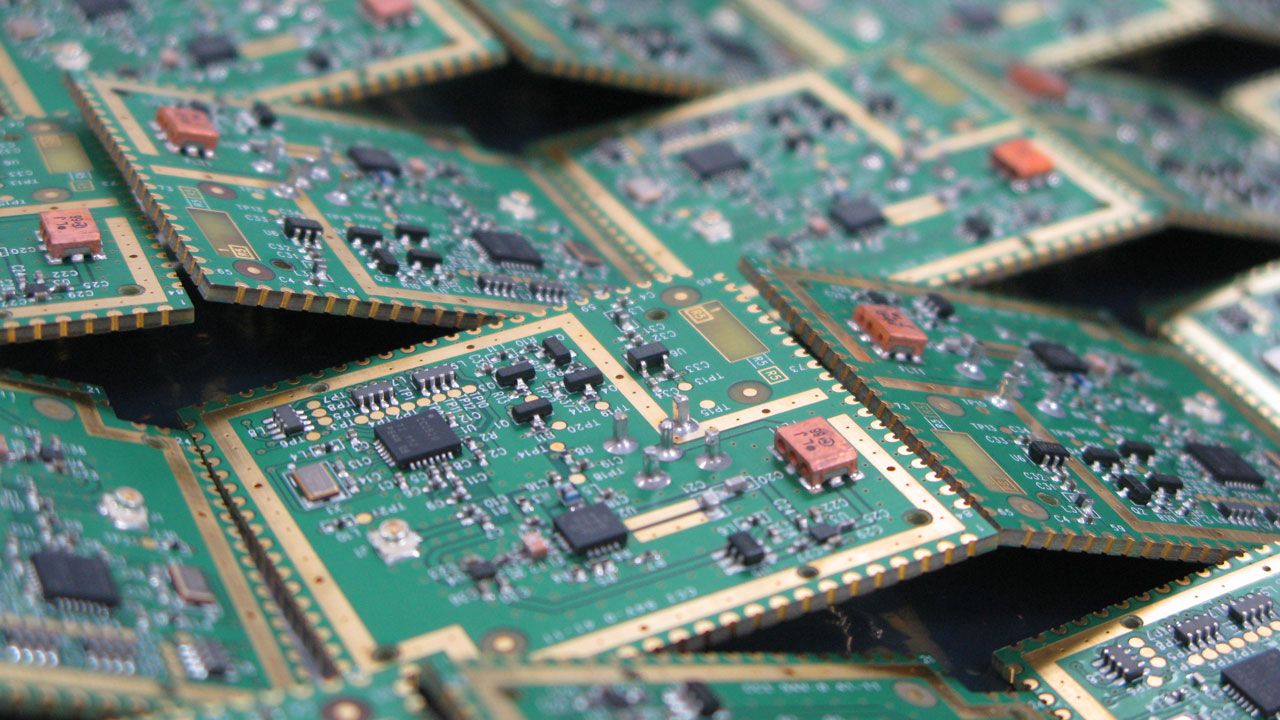

Emerging technologies depend on high-density designs, complex material stacks, and rapid iteration. That’s where manufacturing expertise becomes a competitive advantage.

We support engineers developing systems for autonomous navigation, alternative energy conversion, robotics, and advanced computing. Our design engineering teams integrate electrical and mechanical design considerations early, ensuring a smooth, repeatable, and cost-efficient transition from prototype to production.

At Foxtronics EMS, we see manufacturing not as a handoff but as an extension of innovation, helping transform great ideas into reliable products that scale sustainably.

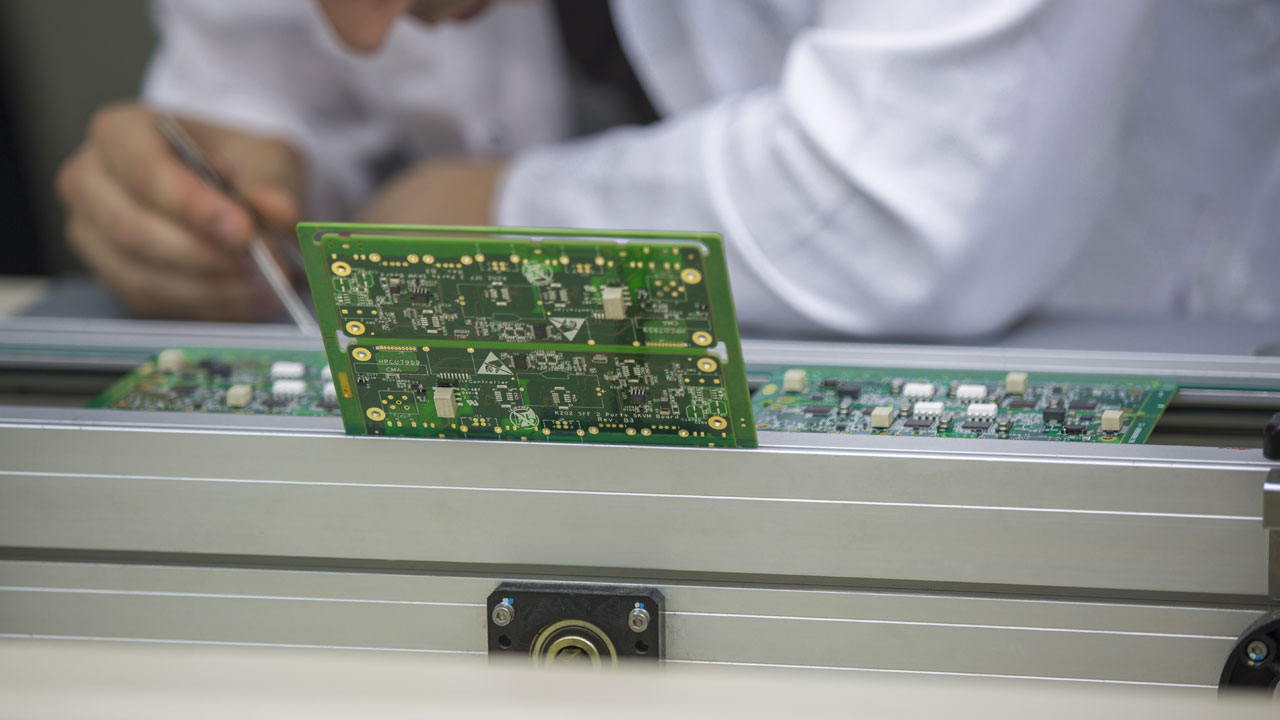

From prototype to production, our facilities support fast-evolving technologies that require precision, validation, and agile manufacturing systems.

From prototype to production, we deliver compact, power-dense PCB assemblies (PCBA) and power-electronics solutions for robotics, EVs, and renewable systems, reducing time-to-market while protecting product longevity through proactive supply‑chain and obsolescence management.

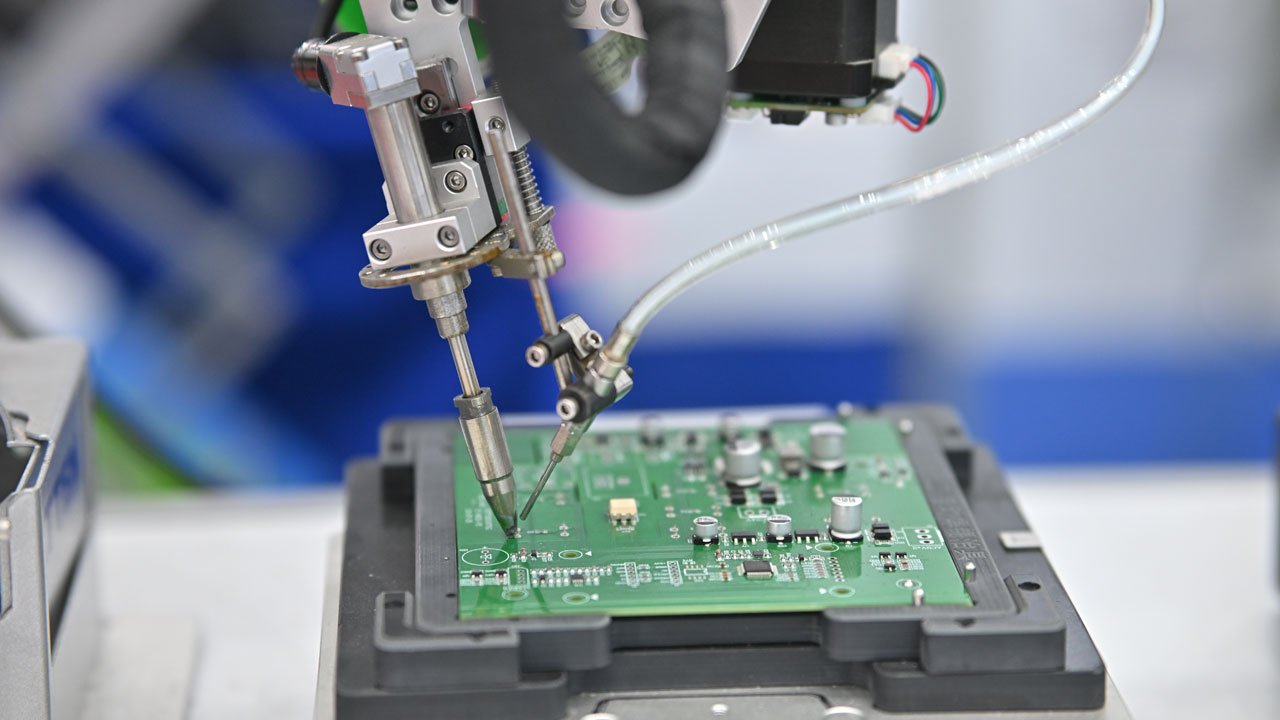

We specialize in multi-layer, HDI, and fine-pitch PCB assemblies for compact systems, including robotics, EV controllers, and advanced sensor platforms. Automated SMT lines and precision reflow ensure high yield and repeatability across builds.

Manufacturing for inverters, converters, battery management systems, and power control modules. Our engineering teams optimize thermal performance and component spacing for safety, efficiency, and longevity.

Design and assembly for wireless modules, control boards, and edge computing devices. We handle both high-mix, low-volume development runs and scalable production of connected hardware.

Fast-turn PCBA builds with direct engineering collaboration to validate layouts, materials, and test coverage. We bridge the gap between R&D and mass manufacturing through flexible, short-run programs.

Functional, in-circuit, and environmental testing ensure every PCB assembly meets electrical and mechanical criteria. Integrated calibration and firmware programming streamline deployment readiness.

Innovators choose Foxtronics EMS because we combine the discipline of manufacturing with an engineering mindset. We understand what’s at stake when scaling a new product from securing component continuity to meeting certification timelines.

Our focus on collaboration, data-driven validation, and transparent communication makes us a trusted partner for companies at the forefront of innovation. We help innovators build reliability into their innovations because every new technology deserves a manufacturing partner that can grow with it.

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

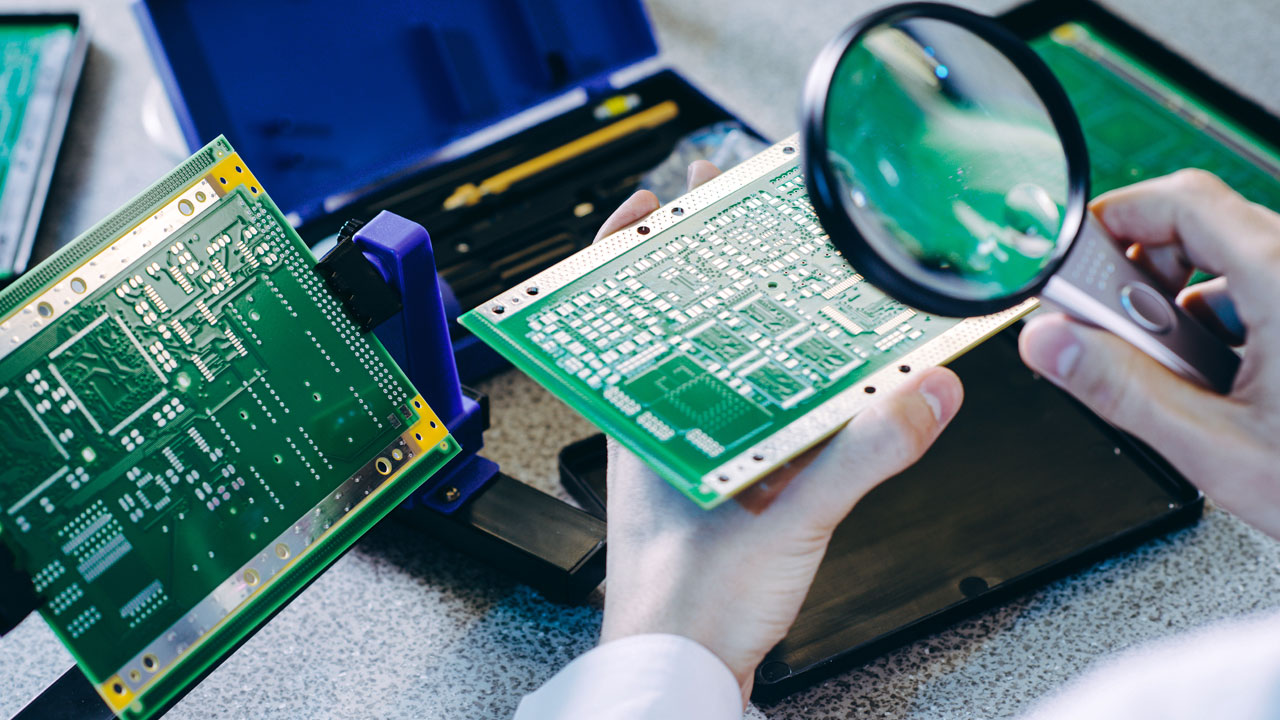

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Find answers to common questions about our PCB assembly for robotics, EVs, renewable energy, and IoT—covering how we help innovators move from prototype to production with reliability and scalability

We work with companies in robotics, electric vehicles, renewable energy, IoT, and advanced computing, providing PCB assembly, testing, and complete product integration.

Yes. We specialize in small-batch and rapid-turn prototypes with direct engineering collaboration to validate design and manufacturability.

Our agile production systems and version control protocols handle frequent design updates while maintaining documentation integrity.

Absolutely. We manage high-current, high-temperature, and power-conversion assemblies with rigorous insulation, spacing, and thermal design protocols.

Yes. Our facilities and supply-chain systems are designed to transition seamlessly from prototype to full-volume manufacturing while maintaining consistent quality.