PCB Assembly for Communications

High-reliability PCB assembly for RF, telecom, and networking systems—engineered for signal integrity, thermal stability, and 24/7 performance across every connection.

Modern communication networks depend on hardware that performs flawlessly — 24/7, in any environment. From cellular base stations and satellite communication systems to data routers and network control boards, every signal counts. Foxtronics EMS supports OEMs that design the infrastructure powering today’s connected world.

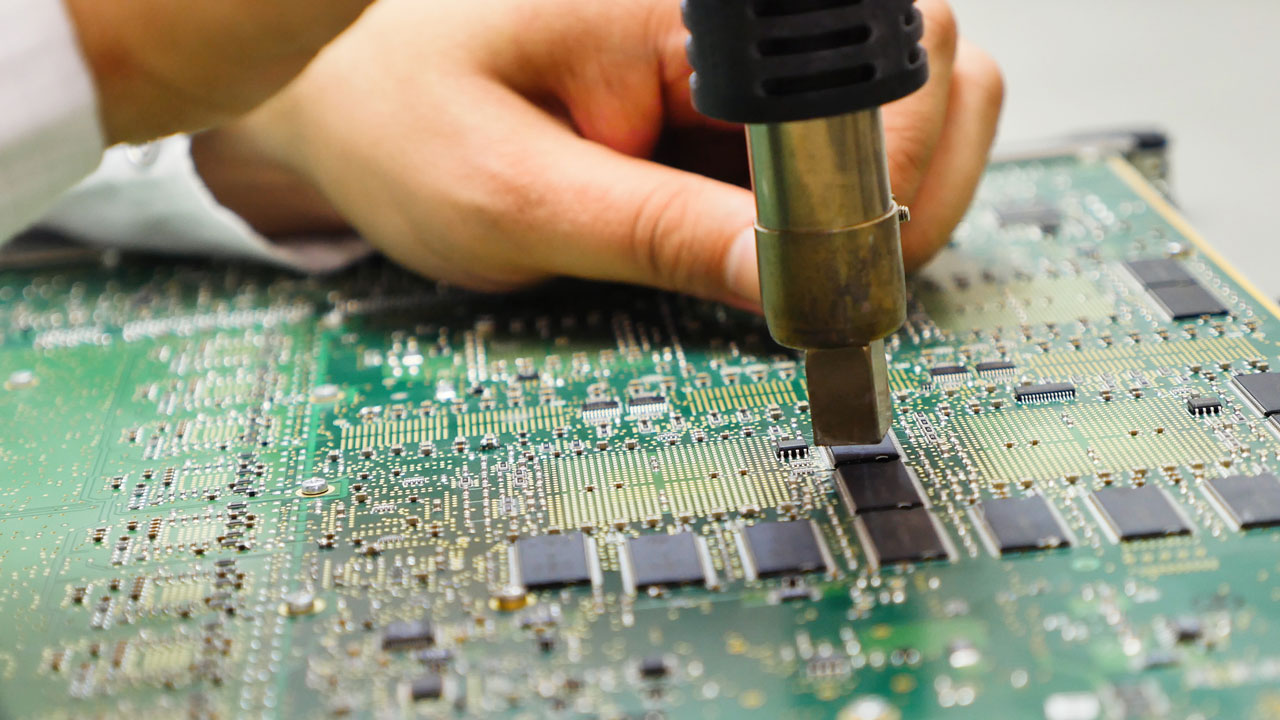

We manufacture RF, microwave, and high-speed digital PCB assemblies that operate under strict electrical tolerances. Our engineers collaborate closely with customers during design review, impedance modeling, and materials selection to ensure consistent transmission performance and thermal stability. Each PCB build follows disciplined process control, validated through precision inspection and test data capture.

Our experience extends across telecom, networking, IoT infrastructure, and communications control systems. Whether it’s a small batch of custom RF modules or a full-scale production run of network backplanes, we help OEMs achieve predictable, scalable, and verified manufacturing outcomes.

Foxtronics EMS combines advanced PCB assembly production capabilities with a systems-level understanding of how signal integrity, thermal design, and assembly precision interact. That’s how we build hardware you can rely on — from lab bench to live deployment.

Every packet, broadcast, or call that moves through a communication network relies on the consistency of its electronics. Even slight variances in impedance, solder uniformity, or material characteristics can degrade performance. That’s why our focus begins with process control and ends with measurable reliability.

We work with controlled-impedance stackups, low-loss materials, and fine-pitch components to ensure stable performance in high-frequency and mixed-signal designs. Functional and RF-specific testing validates electrical behavior, power delivery, and temperature balance under simulated real-world conditions.

For OEMs developing RF front ends, microwave links, networking switches, or IoT gateways, manufacturing is more than assembly — it’s calibration, repeatability, and data-driven control. At Foxtronics EMS, we deliver exactly that.

We combine precision assembly, electrical expertise, and disciplined testing to build communication hardware that performs flawlessly under demanding bandwidth, temperature, and power requirements.

Precision placement, impedance control, and rigorous validation are the foundation of every communications PCB assembly we deliver. Each PCB build is engineered to maintain signal integrity across layers, frequencies, and environments, ensuring consistent performance from lab to field.

Controlled-impedance builds with low-loss materials and precision SMT placement. We specialize in front-end modules, RF amplifiers, transceivers, and satellite communication boards that demand tight phase and gain control. Each design undergoes impedance verification, AOI, and RF testing calibrated to golden units.

Complex PCB assemblies for data routing, switching, and baseband processing with controlled coplanarity and high-lane-count interconnects. Press-fit connector processes and reflow control maintain alignment and continuity under temperature cycling.

From copper-backed PCBs and heatsink integration to thermal interface material (TIM) application, we ensure performance consistency across thermal zones. These practices extend device life, prevent signal drift, and improve energy efficiency.

Functional, in-circuit, and RF performance testing performed with frequency alignment and data capture. Each result is logged under serialized identifiers for traceability and reliability tracking across product lifecycles.

We handle final assembly, wiring, firmware loading, and enclosure integration for telecom and networking systems. Labeling, documentation, and packaging are handled per customer specs, ensuring fast, compliant field rollout.

Strategic sourcing, lifecycle tracking, and alternate part validation to support long-term builds, minimize obsolescence risk, and ensure continuity across global deployments.

Telecom and networking OEMs choose Foxtronics EMS because we combine electronics expertise with communication system insight. We understand what happens when a board leaves the lab and enters a data center, a tower, or a satellite uplink. That understanding drives how we build, test, and document every assembly.

Our process ensures electrical stability, mechanical integrity, and repeatable results, key to reducing deployment risk and service interruptions. Connectivity depends on consistency. That’s why Foxtronics EMS is trusted to deliver communication electronics that work every time, everywhere.

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

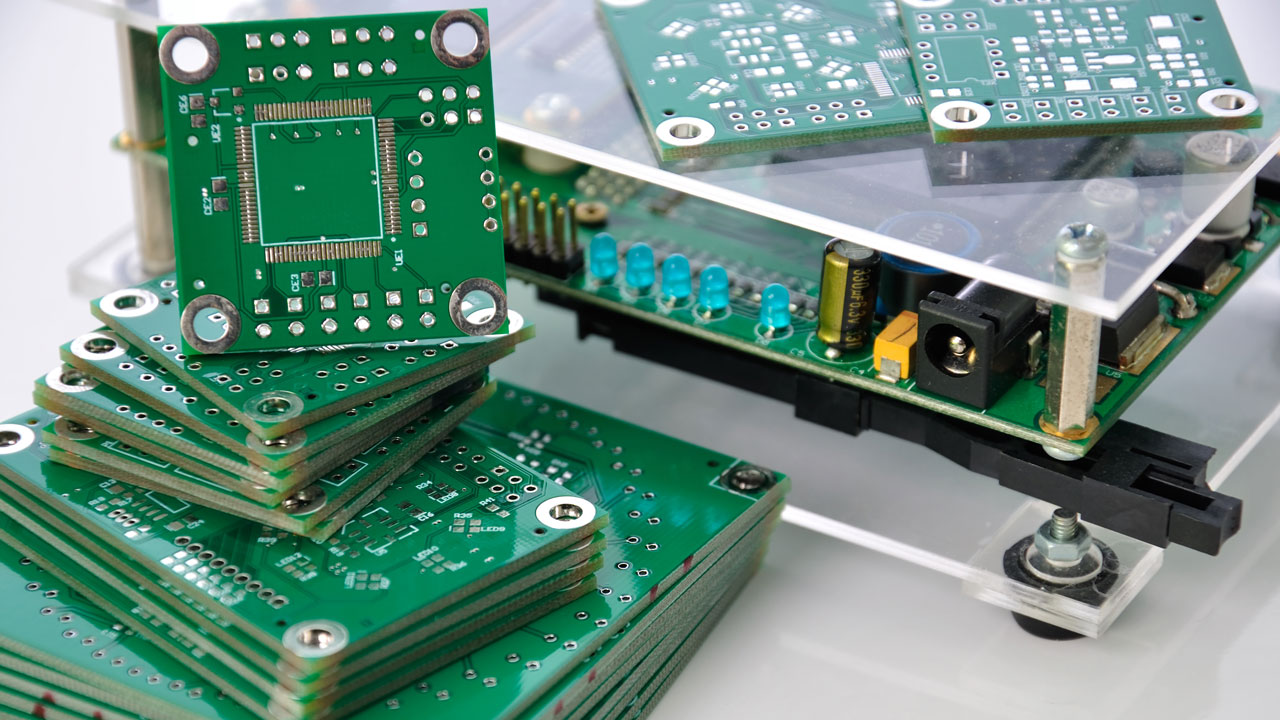

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Find answers to common questions about our RF and telecom PCB assembly, compliance standards, and how we ensure signal integrity and dependable performance across communication systems.

We build RF modules, microwave amplifiers, baseband boards, networking switches, IoT gateways, and control systems for telecom and broadband infrastructure.

We verify impedance stackups, apply precision reflow control, and inspect every PCB assembly using X-ray and AOI to ensure stable signal paths and connector alignment.

Yes. We conduct RF alignment, tuning, and calibration against customer-defined golden units to confirm performance metrics and repeatability.

Absolutely. Our engineering team advises on materials, heatsinks, and thermal balance to maintain component stability and prevent drift in high-power applications. Learn more about our Thermal Management Techniques.

Yes. Our builds align with IPC Class 2/3, RoHS, and applicable telecom and CE compliance documentation.