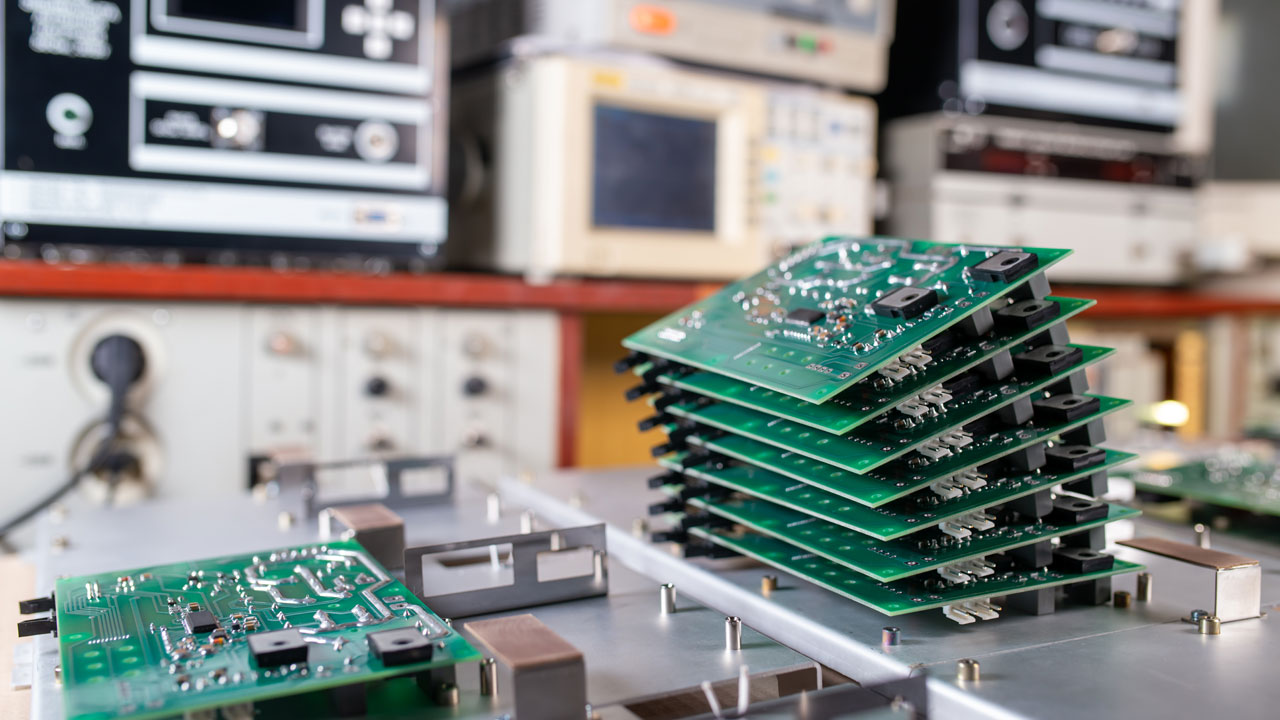

PCB Assembly for Commercial Electronics

Cost-effective, high-quality PCB assembly and product integration for commercial devices — designed for reliability, consistency, and market-ready performance.

From smart home devices to industrial controls and retail technology, the world’s most familiar products depend on electronics that perform flawlessly under everyday use. At Foxtronics EMS, we turn innovative designs into stable, repeatable products ready for market, whether you’re launching a new device or scaling an established line.

Our expertise covers connected electronics, lighting systems, POS and payment terminals, control modules, and smart appliances. We understand the balance between technical precision and cost optimization, designing processes that protect your quality while maintaining commercial agility.

Our teams collaborate with product developers early in the design stage to optimize layouts, streamline sourcing, and select materials that align with both functional and commercial goals. Each PCB assembly is produced under IPC Class 2 or Class 3 standards, depending on product requirements, with testing strategies tailored to ensure long-term reliability.

The result is a smooth transition from prototype to full production and from production to consistent global supply.

In commercial electronics, success hinges on providing reliability at scale and at a price the market can sustain. That’s why Foxtronics EMS focuses on process efficiency, supply-chain coordination, and engineering precision at every step.

Our approach goes beyond the board itself. We design for manufacturability, testability, and sustainability. Whether your product must meet regional safety certifications, minimize environmental impact, or support quick configuration changes, our flexible manufacturing systems are designed to keep up.

By pairing advanced automation with disciplined process control, we deliver PCB assemblies that meet expectations on quality, cost, and delivery, helping brands strengthen margins without compromising dependability.

From connected home devices to enterprise-grade systems, we provide scalable manufacturing and integration solutions that meet technical, aesthetic, and market-driven demands.

Fully assembled, tested, and professionally packaged electronics ready for integration, ready for market. Each unit is built to meet your specifications, with documentation, labeling, and packaging tailored for seamless handoff to final production or distribution.

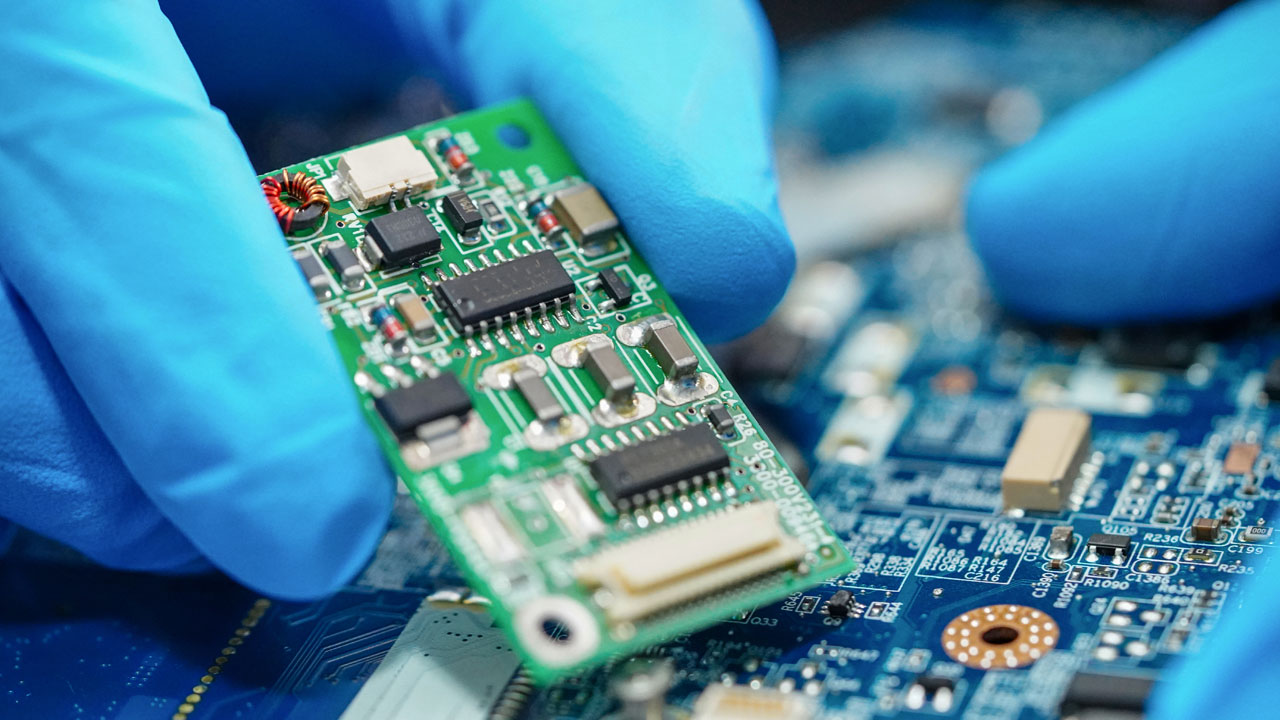

We specialize in high-mix SMT assembly and through-hole assembly for smart, connected, and industrial commercial products. From quick-turn prototypes to full-scale production runs, we manage rolling engineering changes with precision, ensuring traceability, compliance, and consistent quality throughout.

Support for advanced PCB assemblies, including Rigid & HDI, Flex & Rigid Flex, and RF/microwave assemblies, used in compact, high-speed commercial products built to meet signal integrity, impedance, and layout constraints without compromising manufacturability.

Turnkey system assembly, including enclosure integration, cabling, labeling, and packaging. We prepare complete kitted solutions with documentation, accessories, and serial tracking, ready for direct distribution or drop shipment.

Each product undergoes functional and reliability testing per customer specification, including burn-in, ESD, and regulatory safety checks. We also prepare compliance documentation for UL, CE, and FCC certifications as required.

We work closely with customer planning teams to align component sourcing with forecasts, manage lead times, and secure alternates. Our goal: ensure your production schedule never stalls for lack of material.

Our DFM and DFT support helps simplify builds, reduce assembly costs, and accelerate validation. We also assist with firmware loading, calibration, and version control during production.

Foxtronics EMS blends commercial agility with industrial-grade discipline. Our systems are flexible enough for frequent design updates and rigorous enough for sustained, high-volume production.

We treat every build, whether it’s a commercial device or an enterprise control unit, as a long-term partnership focused on speed, quality, and scalability. From initial concept to market release, we help OEMs build products that perform dependably, look great, and ship on time.

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

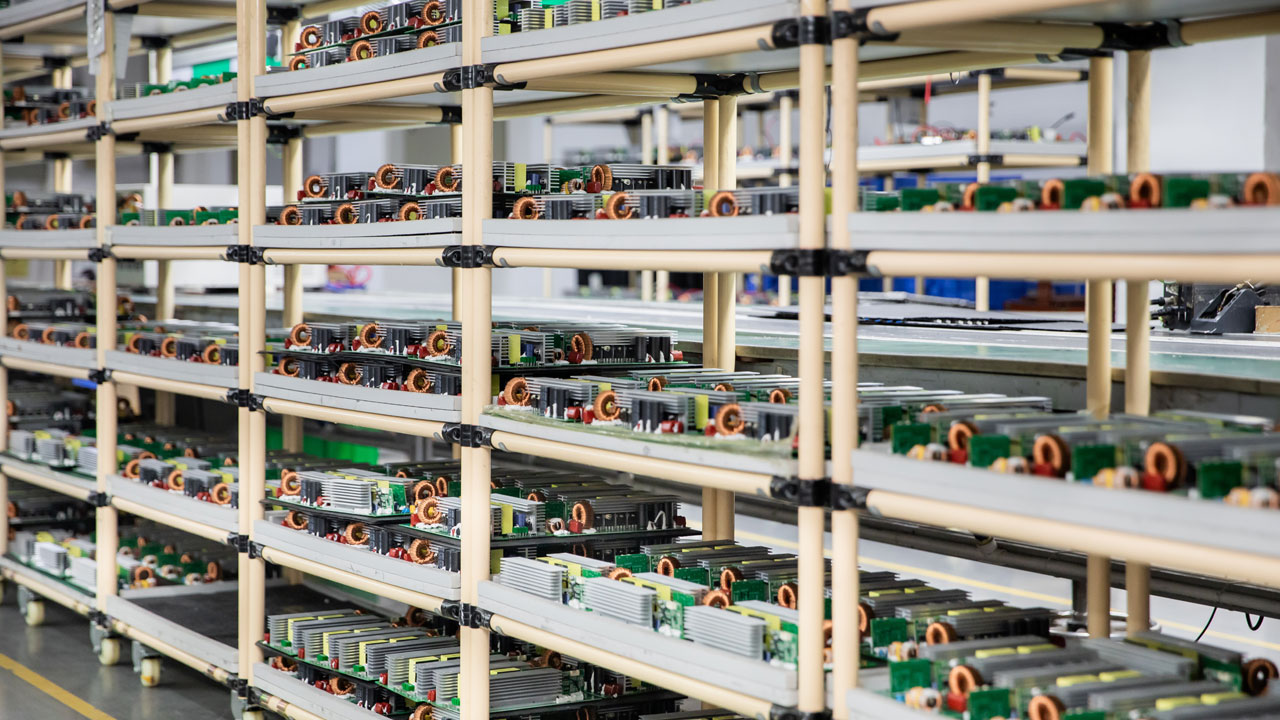

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

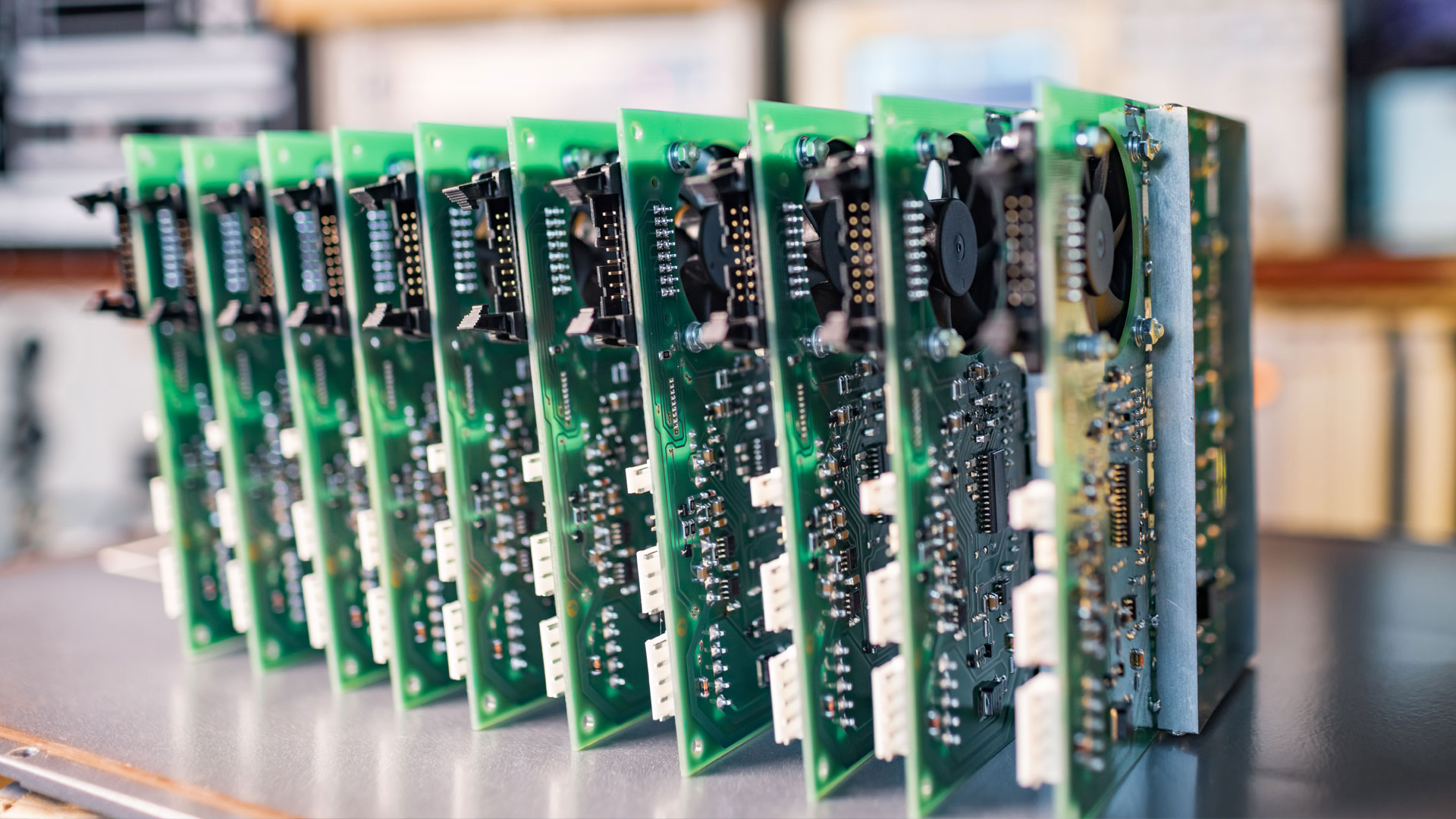

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Get answers to common questions about our commercial electronics PCB assembly, turnkey solutions, and how we ensure consistent quality, scalability, and reliable performance for commercial and industrial devices.

We assemble electronics for smart appliances, control modules, lighting systems, POS terminals, and other connected or enterprise-grade products.

Yes. Our production model supports rolling ECNs and short-turn modifications without disrupting established schedules.

Absolutely. We prepare supporting documentation and testing data for UL, CE, and FCC certifications to simplify compliance.

Through early DFM input, supplier collaboration, and lean manufacturing methods that reduce waste and optimize component use.

Yes. We deliver complete box-build, labeling, and kitting solutions so your products are ready for shipment or retail fulfillment.