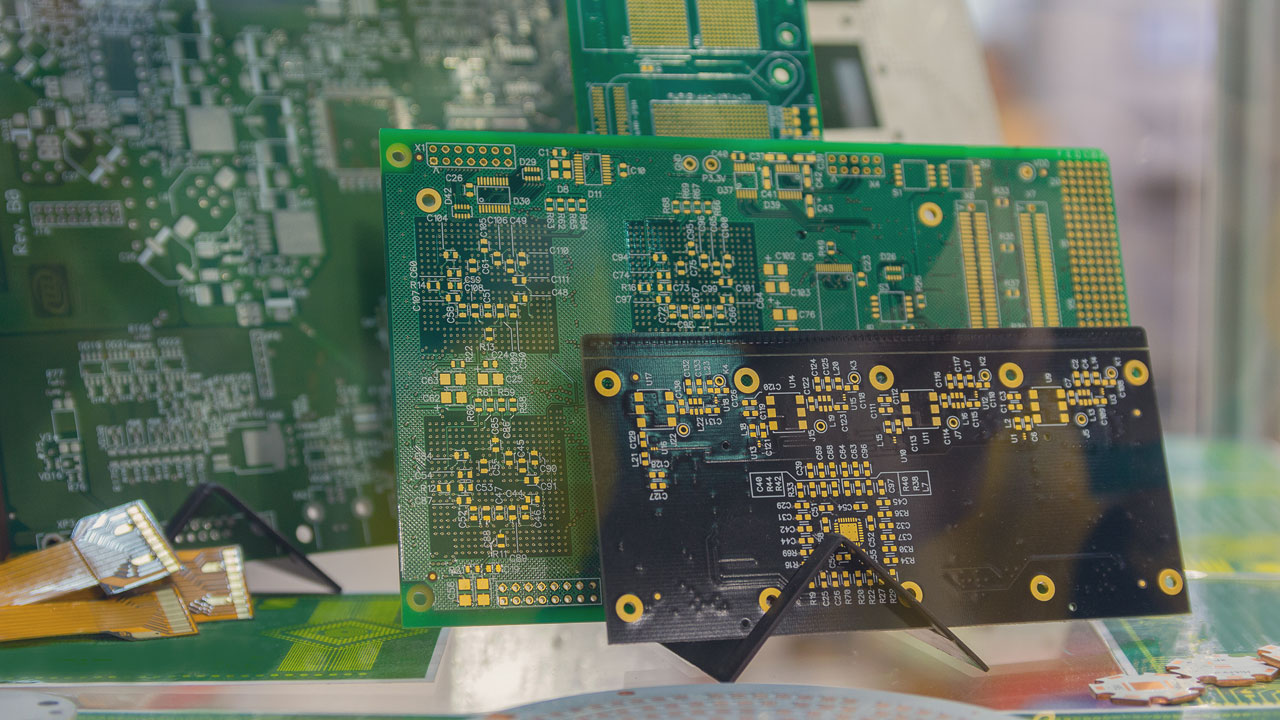

Foxtronics EMS assembles rigid and HDI PCBAs using advanced fabrication partnerships. Our process engineers work closely with your team to define stack-ups with controlled impedance, balanced copper distribution, and low-loss dielectrics.

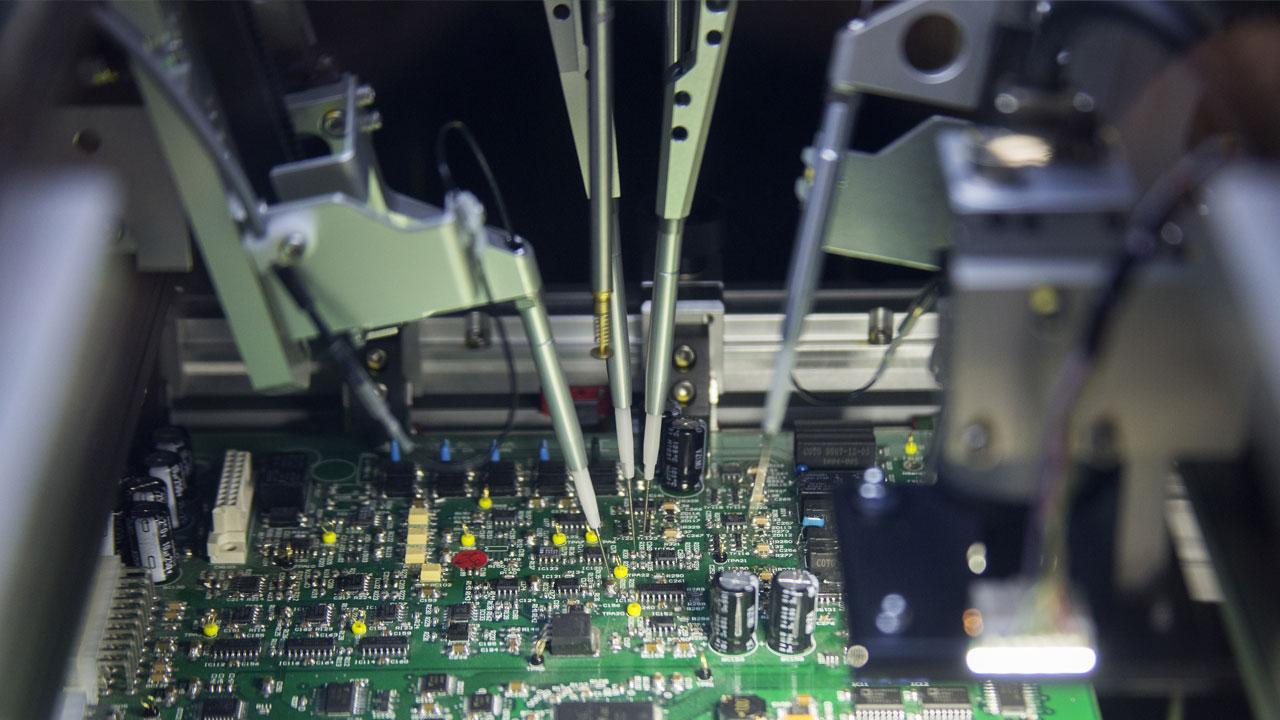

Because these dense interconnects operate at the edge of performance, we embed Design for Manufacturability (DFM) and Design for Test (DFT) reviews early. You’ll receive actionable input on trace/space limits, via-in-pad planning, copper wrap, aspect ratios, CAF mitigation, and thermal relief long before tooling begins.

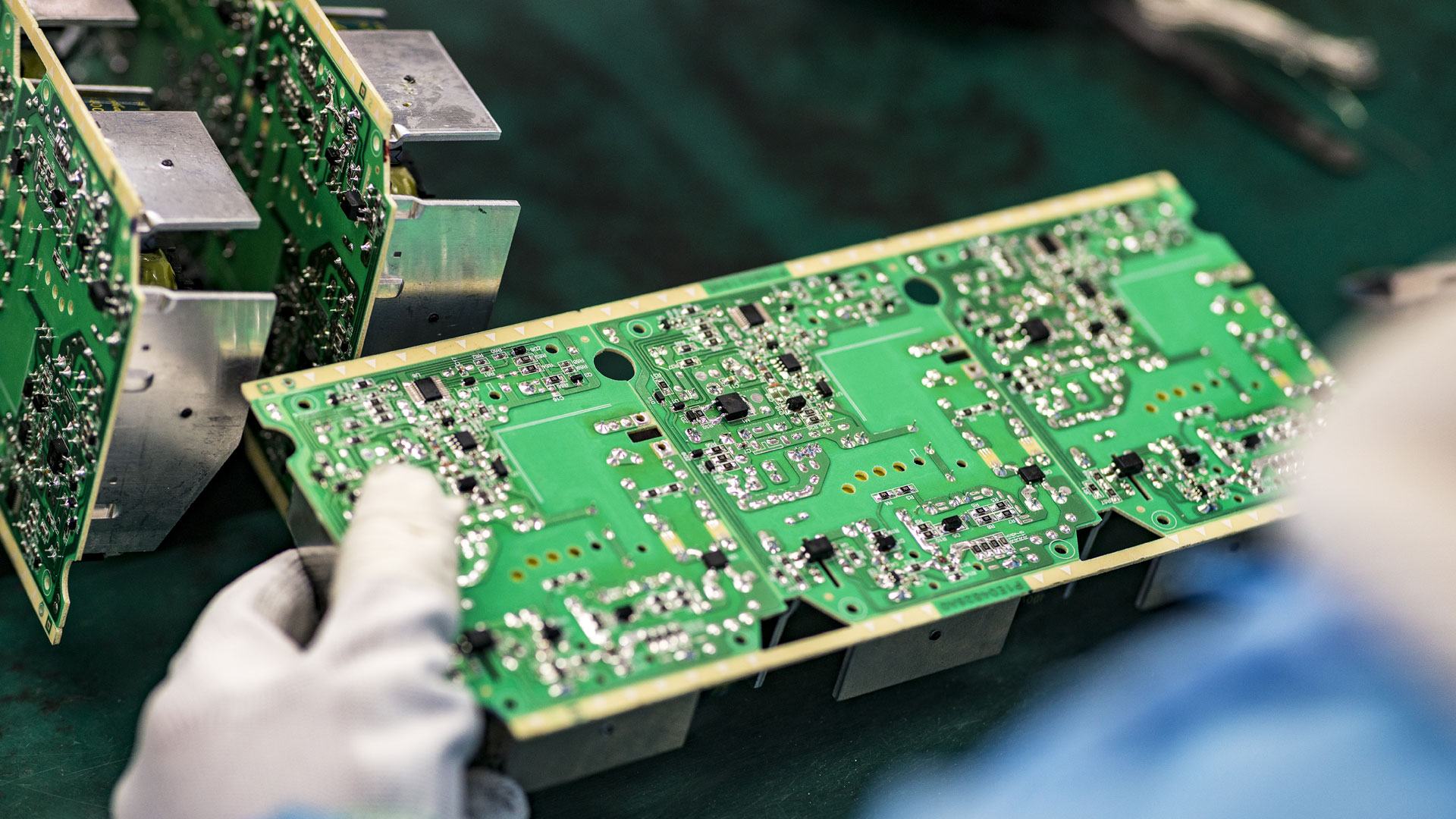

From aerospace sensors to compact medical devices, our expertise accelerates development, improves first-pass yield, and ensures consistency from prototype to production.