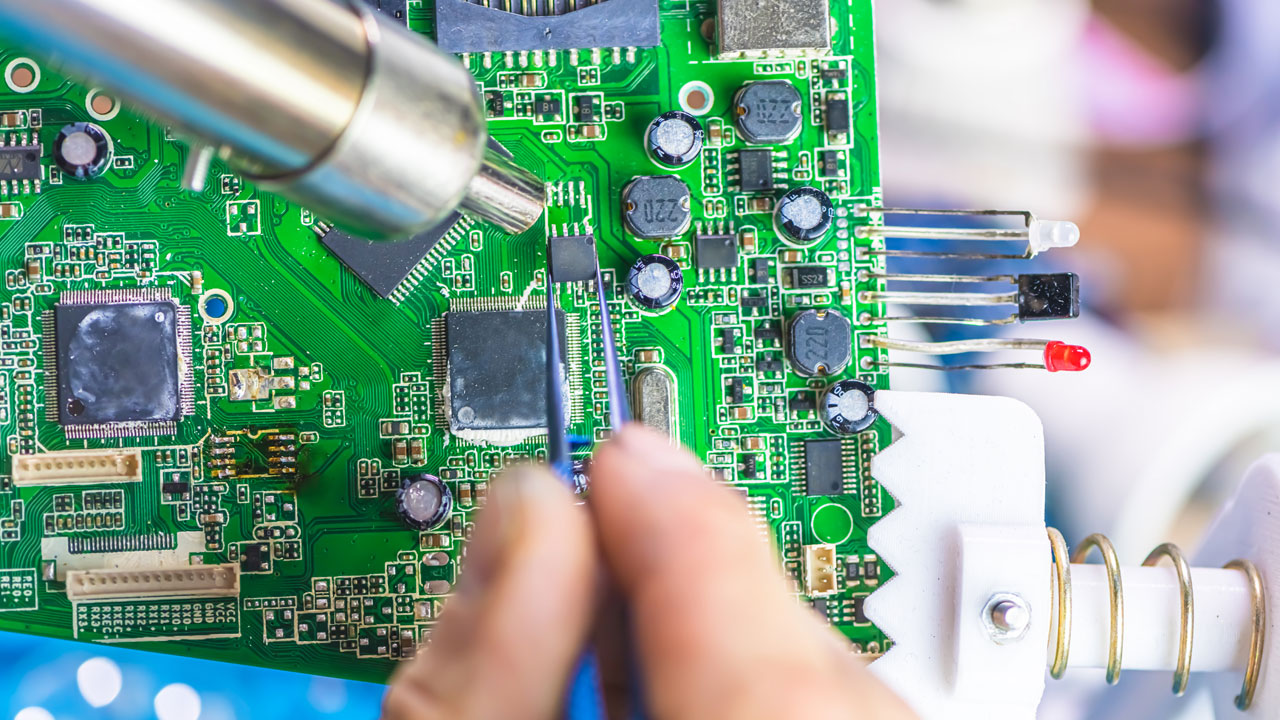

As electronic devices continue to shrink while growing more complex, traditional rigid boards can no longer meet the spatial and mechanical demands of modern applications. Flex and rigid flex PCBAs provide an ideal solution, offering the electrical performance of standard assemblies with the added advantage of mechanical flexibility. Built on high-performance polyimide substrates, these assemblies bend, twist, or fold into compact enclosures without sacrificing circuit integrity or reliability.

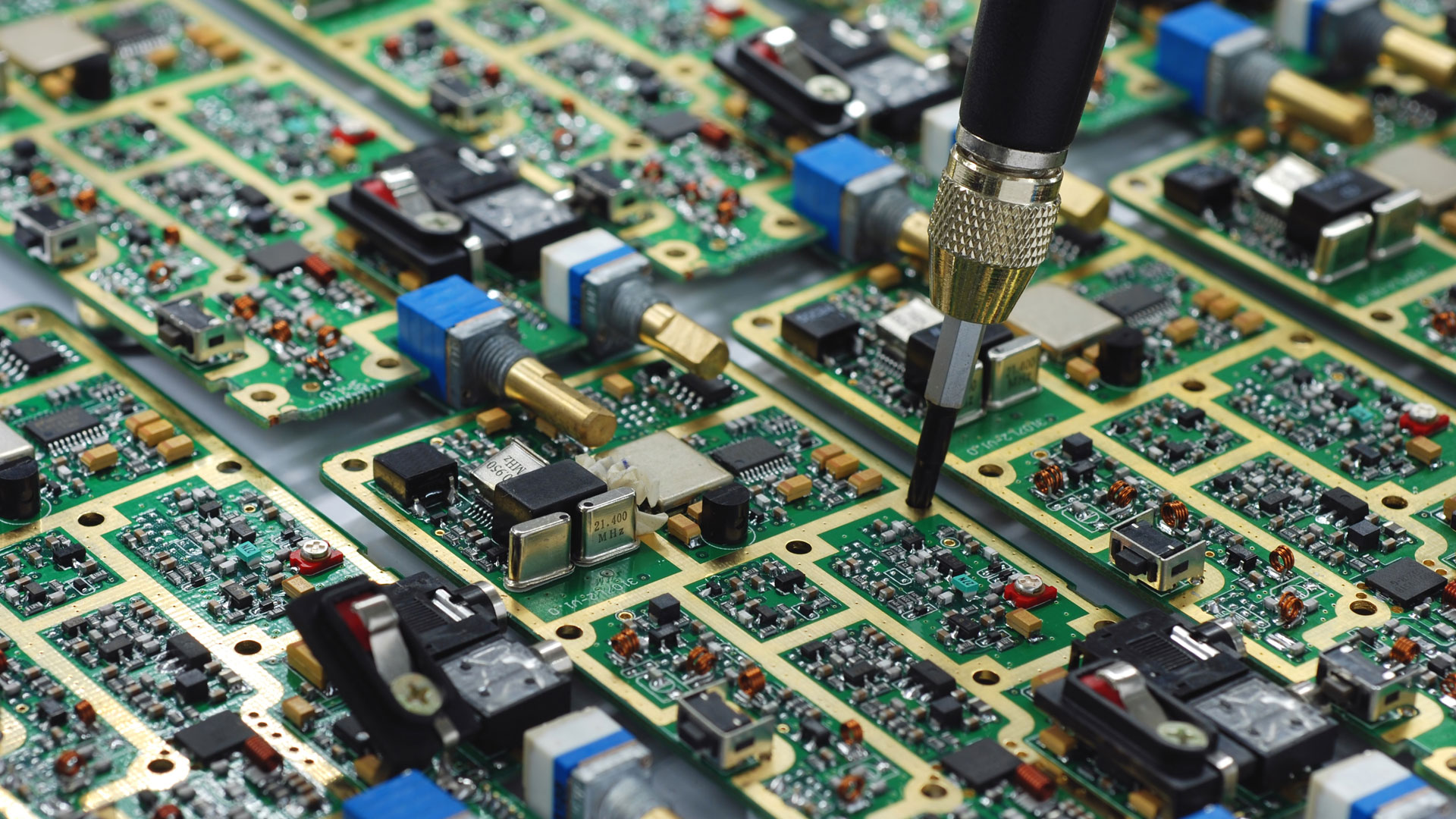

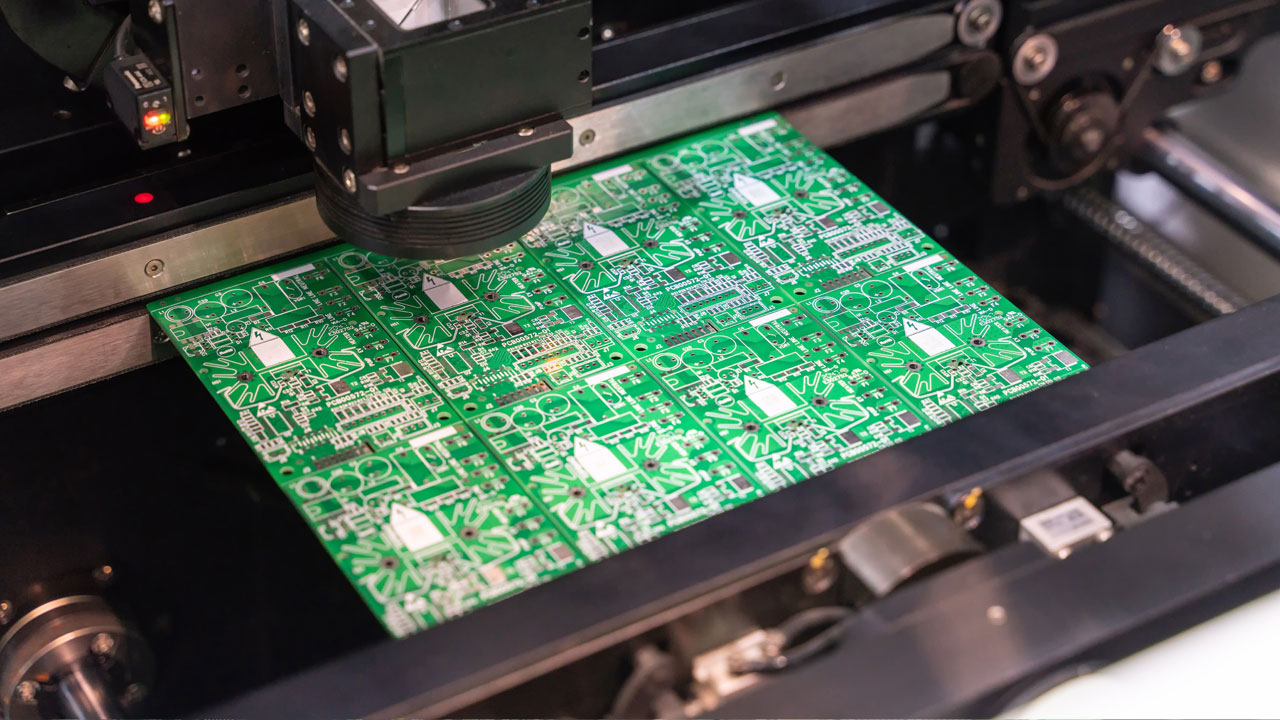

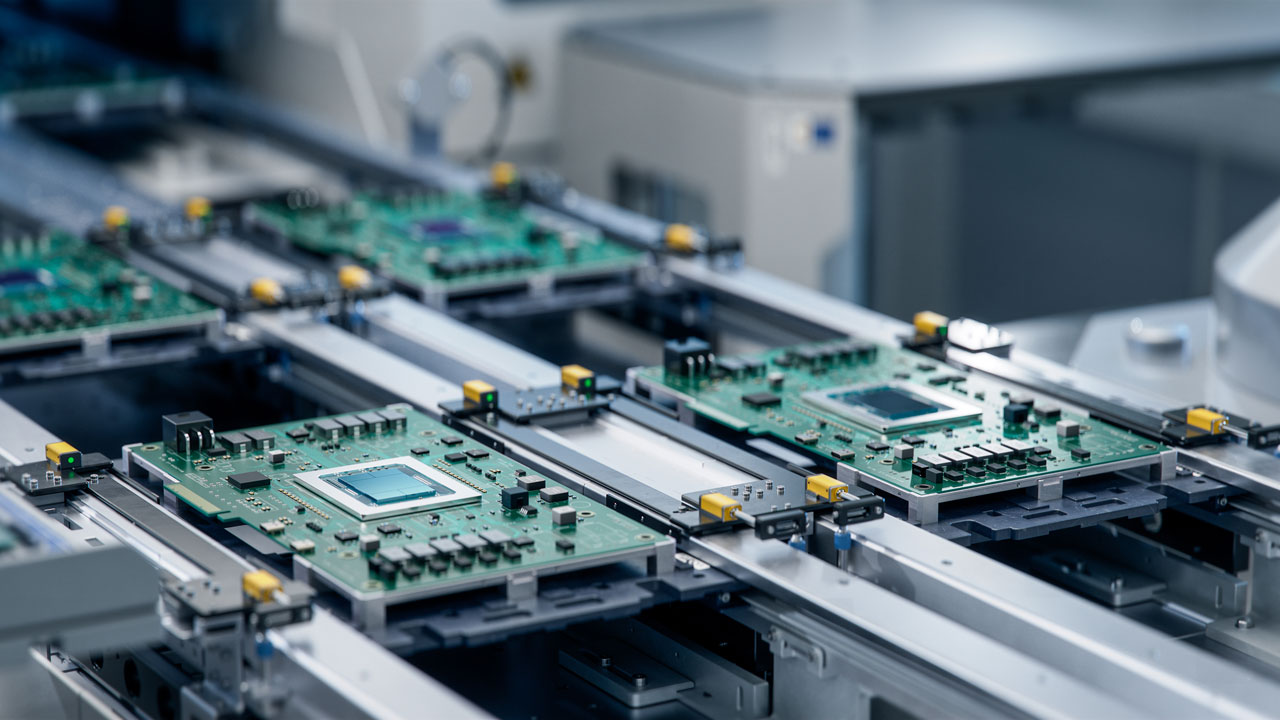

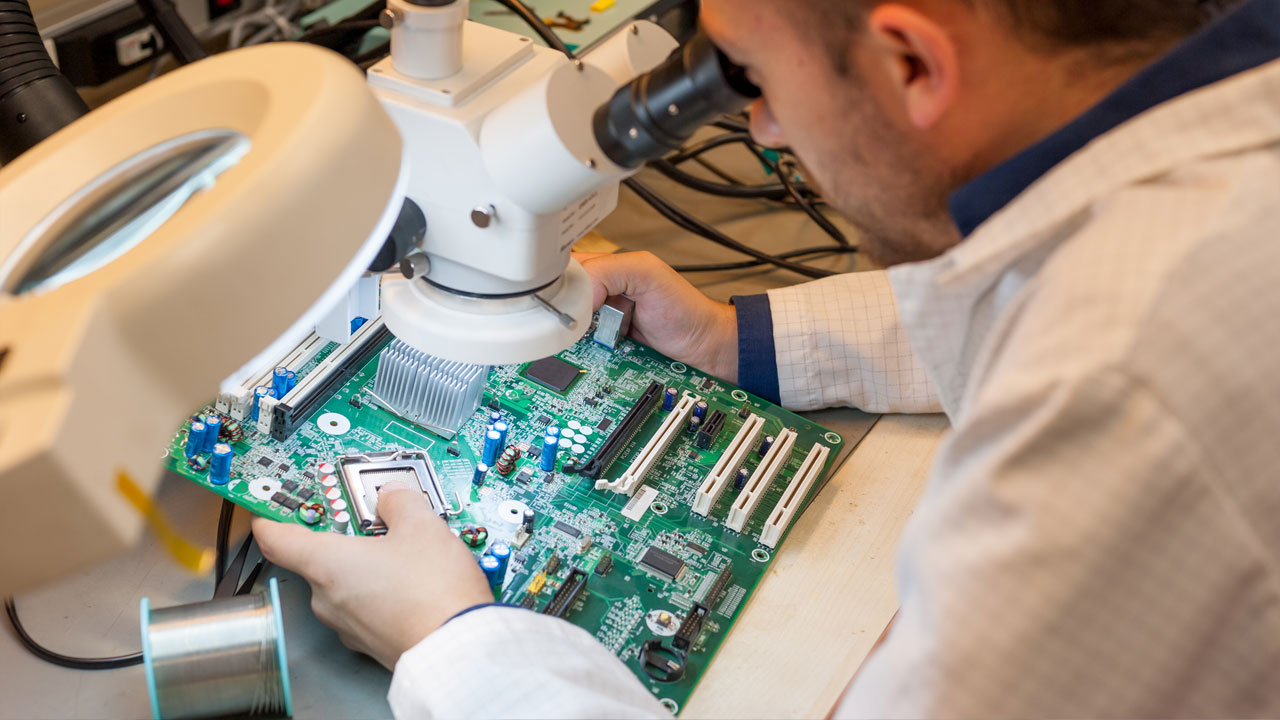

Foxtronics EMS specializes in the assembly of high-reliability flex and rigid flex PCBs, engineered to perform in harsh environments, under repetitive motion, and across dynamic mechanical stresses. From basic single-layer flex circuits to complex multilayer rigid flex assemblies with Surface Mount Technology (SMT) and Through-hole integration, our solutions reduce interconnects, lower failure risks, and support compact, lightweight product designs.

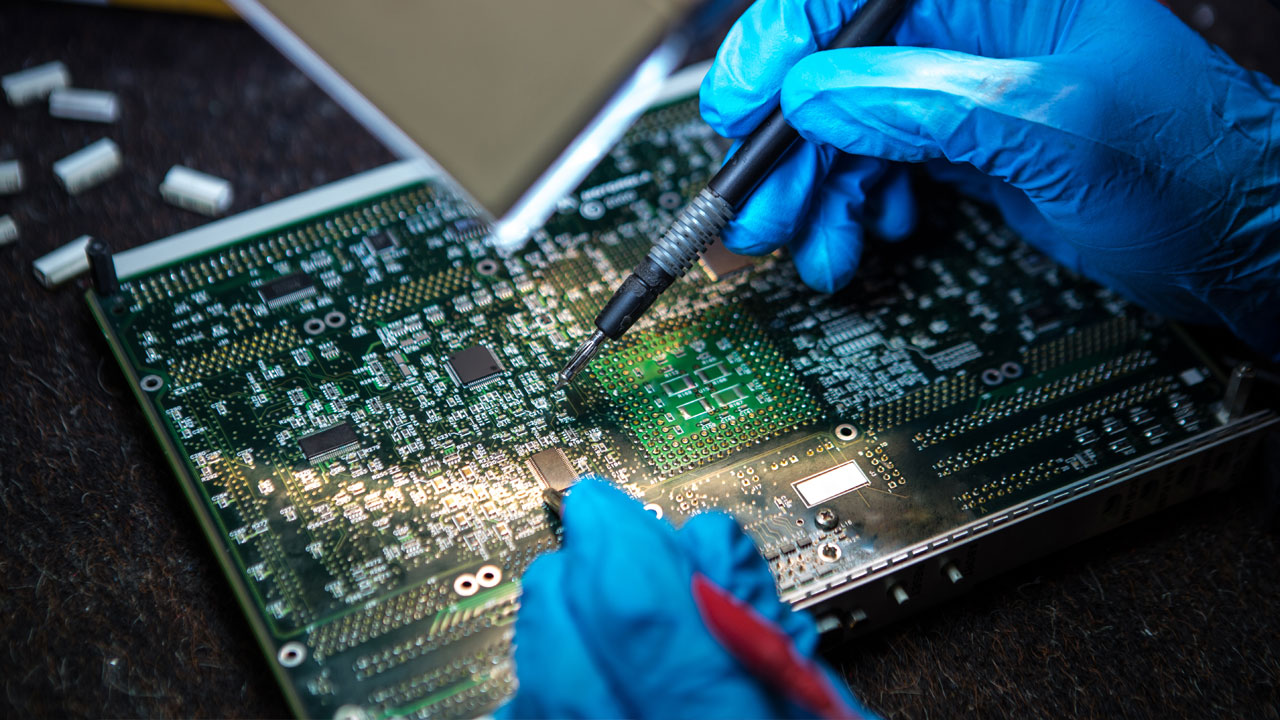

We work closely with OEMs across sectors like medical, aerospace, and industrial to develop custom flex PCB assemblies that meet strict dimensional, performance, and environmental specifications. With capabilities that include impedance-controlled traces, fine-pitch BGA and QFN placement, EMI shielding, and stiffener integration, we help you deliver innovation that fits—literally and functionally—into the most demanding form factors.