Table of Contents

Controlling Heat for Reliable Performance

Every electronic device generates heat during operation, and managing that heat is essential to ensure consistent performance and reliability. In high-density printed circuit board (PCB) assemblies, improper thermal control can lead to component failure, solder fatigue, or long-term degradation of materials.

At Foxtronics EMS, our engineering and manufacturing teams understand that thermal management is not an afterthought — it is an integral part of PCB design, layout, and process planning. By combining material science, design optimization, and advanced PCB assembly techniques, we help customers maintain performance even in the most demanding environments.

1. The Importance of Thermal Management

Thermal management ensures that heat is efficiently transferred away from critical components and evenly distributed across the printed circuit board. As electronic designs become smaller and more powerful, the challenge of controlling heat intensifies.

Without proper planning, excessive heat can cause:

- Drift in component performance

- Solder joint cracking or fatigue

- Delamination or warping of circuit layers

- Reduced product lifespan

Foxtronics addresses these issues early through simulation, material selection, and process control, ensuring every PCB assembly can sustain its performance under continuous load.

2. Material Selection and Heat Dissipation

The foundation of good thermal performance begins with material selection. The choice of laminate, copper thickness, and thermal interface materials determines how effectively heat moves through the assembly.

Key material considerations include:

- Copper Weight: Thicker copper layers increase the ability to spread heat and handle higher current densities.

- Dielectric Material: Laminates with higher thermal conductivity improve heat flow between layers.

- Thermal Vias: Strategically placed vias create vertical heat paths from surface components to internal or bottom layers.

At Foxtronics, our Supply Chain Management teams work with trusted material suppliers to select and verify substrates that meet thermal and mechanical requirements, ensuring each design stays stable through manufacture and field use.

3. PCB Design Techniques for Heat Control

The layout and physical design of a PCB play a major role in how heat is distributed and dissipated.

Our design engineers collaborate with customers to implement design strategies such as:

- Placing high-power components near heat sinks or airflow paths

- Using thermal relief patterns to balance soldering heat flow

- Designing balanced copper distribution to avoid hot spots

- Implementing split planes for power and ground to separate thermal zones

By integrating these thermal principles into the design stage, Foxtronics EMS helps customers prevent problems that might otherwise appear late in production or during field operation.

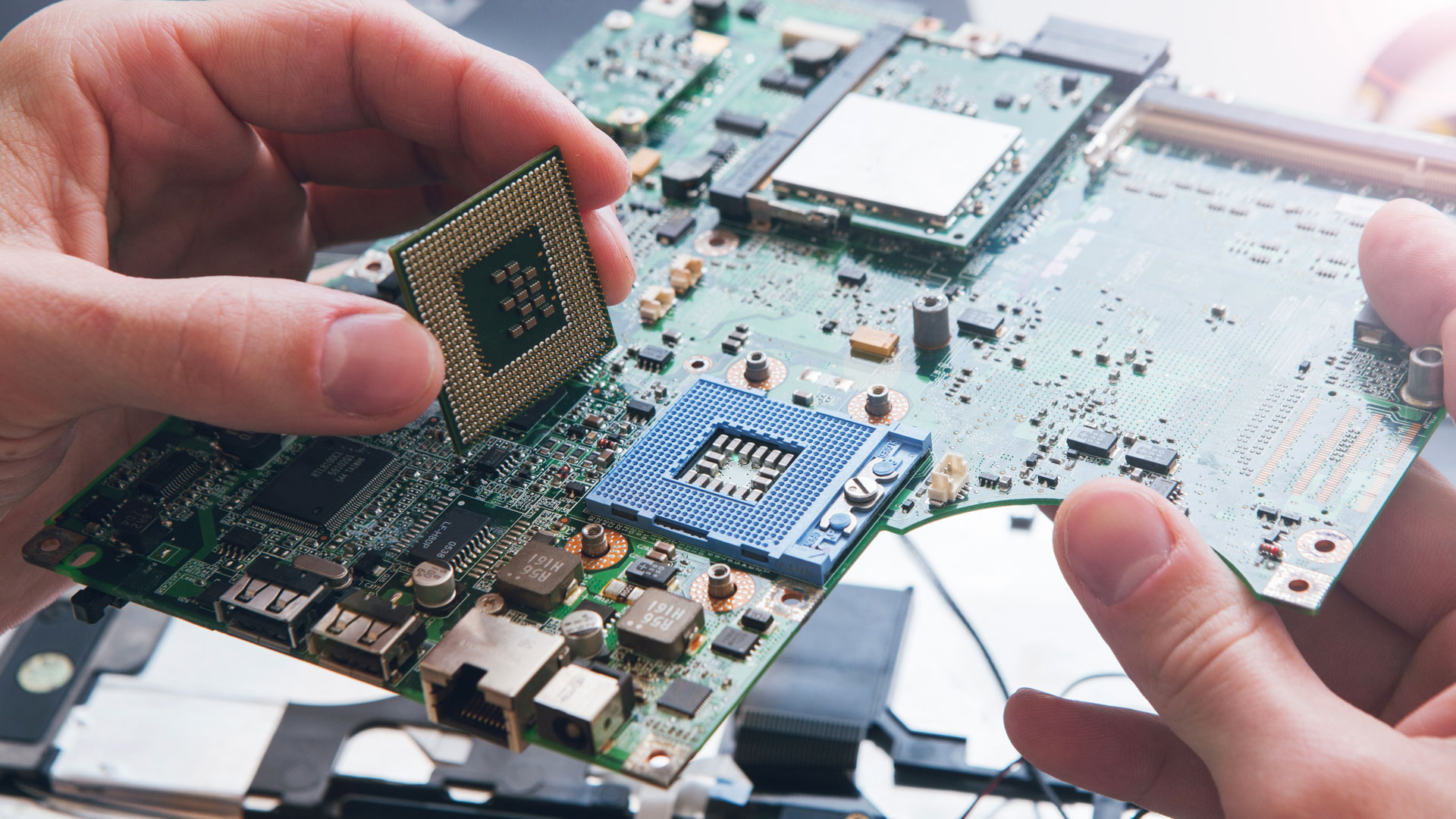

4. Heat Sinks and Component-Level Cooling

When component temperatures exceed safe limits, mechanical cooling solutions become necessary.

Foxtronics EMS supports the integration of heat sinks, thermal pads, and other component-level solutions to manage localized hot spots.

We evaluate each PCB assembly for the best combination of passive and active cooling, including:

- Heat sinks with conductive interface materials

- Thermal pads that bridge components to the chassis or shields

- Active airflow systems for high power modules

Our teams ensure that these additions do not interfere with mechanical fit, assembly automation, or reflow soldering profiles.

5. Advanced Thermal Interface Materials

Thermal interface materials (TIMs) fill microscopic air gaps between surfaces, improving heat transfer from components to heat spreaders or enclosures.

Foxtronics EMS sources and applies a wide range of TIMs depending on product requirements, including:

- Thermal greases and phase change materials for high-performance modules

- Gap fillers for uneven surfaces or height variations

- Adhesive pads for ease of application and rework compatibility

Each material is validated for conductivity, curing characteristics, and process compatibility to ensure repeatable results during production.

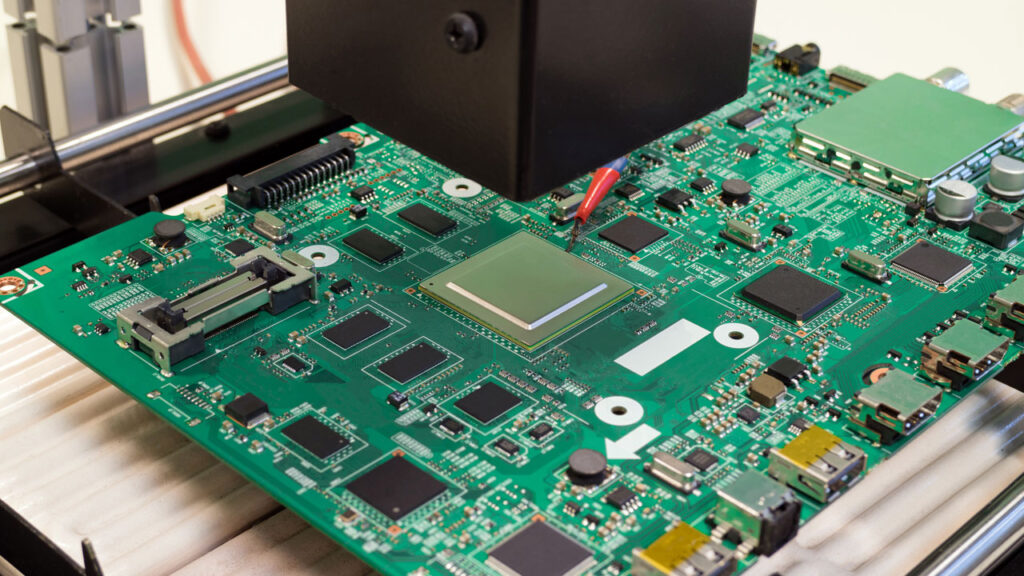

6. Manufacturing Controls That Protect Thermal Balance

Beyond design and materials, manufacturing consistency is crucial to maintaining thermal performance.

Foxtronics EMS enforces process controls that keep PCB assemblies thermally uniform and mechanically stable, including:

- Profile optimization in reflow and wave soldering

- X-ray and thermal imaging inspection for voids and uneven joints

- Verification of heat sink and TIM placement accuracy

- Controlled cooling cycles to prevent stress in multilayer boards

By managing temperature profiles during every step of production, we preserve solder integrity and protect sensitive components from thermal shock.

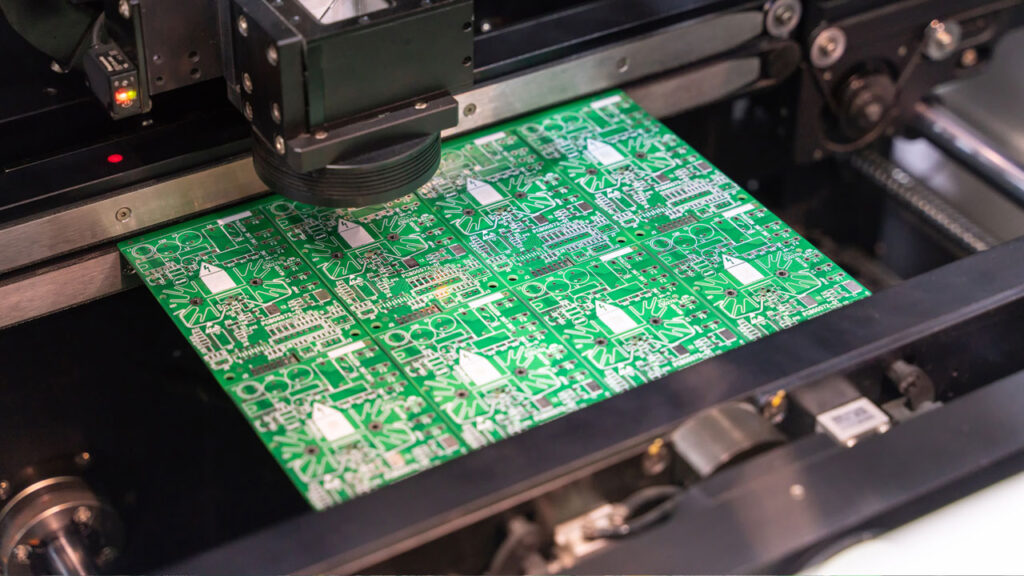

7. Testing and Validation

Our testing processes confirm that every assembly performs under expected thermal loads. Foxtronics EMS conducts functional burn-in testing, infrared thermal analysis, and real-time data logging to ensure heat management systems operate as intended.

We document and store results through our traceability system, allowing customers full visibility into each build. This data-driven approach ensures that thermal performance remains consistent from prototype through full-scale production.

Conclusion: Heat Control Built Into Every Design

Effective thermal management is the difference between a board that functions temporarily and one that performs reliably for years. At Foxtronics EMS, we integrate thermal design, materials science, and precise process control at every stage of PCB assembly. Our commitment to heat control ensures that customer products stay cool, stable, and dependable under the toughest conditions.

If your electronic design demands advanced heat management and reliability, Foxtronics EMS can help.

Contact our engineering team to learn how we optimize materials, layouts, and processes to deliver thermally balanced and performance-driven PCB assemblies.