PCB Assembly for Agriculture

Rugged PCB assemblies and integrated electronic systems for precision agriculture, off-highway equipment, and smart farming, built to perform in harsh field conditions.

Agricultural and off-highway equipment operate in some of the harshest environments on earth. Dust, vibration, moisture, and electrical transients are a daily challenge, and failure isn’t an option during critical harvest or planting windows. To meet these demands, electronics must be ruggedized, protected with coatings, and validated for performance under real-world stressors.

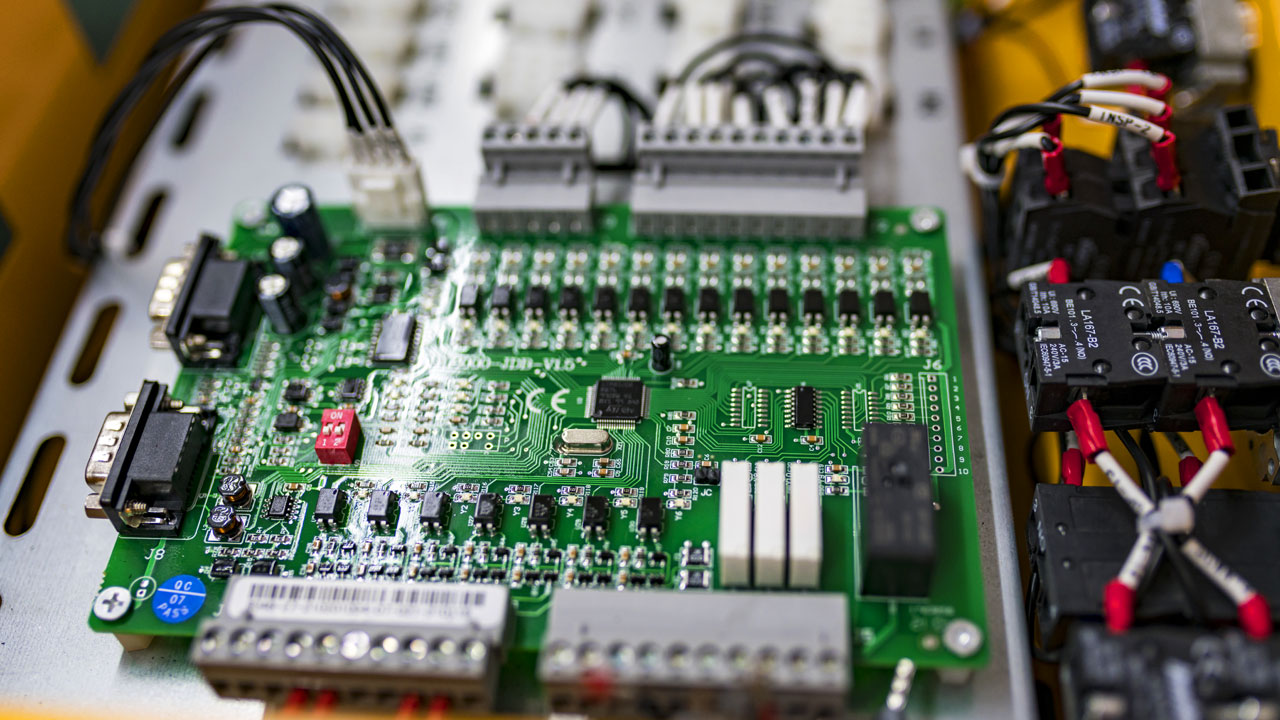

Foxtronics EMS builds electronics engineered for reliability in the field, from control modules and sensor hubs to power management and telematics systems. Our PCB assemblies power modern tractors, irrigation controls, seeding systems, and connected agricultural machinery, keeping farms running efficiently and productively.

Our design engineering teams understand both the mechanical and electrical demands of agricultural systems. We collaborate early with OEM design teams to validate component choices, optimize PCB layouts for environmental exposure, and define test profiles that replicate real-world conditions. Every build follows IPC Class 2 or Class 3 workmanship standards, with additional protective processes such as conformal coating, potting, and sealed connectors—the result: durable, traceable PCB assemblies that perform reliably in any season, on any terrain.

Agricultural equipment doesn’t get the luxury of controlled environments. Systems must survive rapid temperature shifts, dirt intrusion, vibration, and power fluctuations, often while handling mission-critical automation tasks.

Foxtronics EMS designs its manufacturing processes around those realities. We implement various testing methods, including environmental testing, transient suppression, and selective conformal coating, to protect sensitive components. Our documentation and traceability systems ensure every board can be traced to its origin, critical for OEMs managing large fleets or distributed service programs.

By combining rugged design principles with disciplined process control, we help equipment manufacturers reduce field failures, extend product lifecycles, and support long-term serviceability. For an industry driven by uptime, that reliability is worth more than any specification sheet.

We build electronics that power precision agriculture, smart irrigation, heavy machinery, and fleet-connected systems — all designed for real-world endurance.

By combining ruggedized assembly, environmental testing, and system-level manufacturing with the responsiveness and transparency trusted by agricultural OEMs, Foxtronics EMS delivers field-ready electronics that withstand seasonal extremes, reduce unplanned downtime, and enable smarter, more resilient field operations.

We produce coated, mechanically reinforced PCB assemblies for controllers, displays, lighting systems, and telemetry units. Each PCB undergoes AOI, in-circuit, and environmental testing to verify strength and functionality under vibration and temperature stress.

Design and assembly of motor, pump, and lighting controllers with integrated surge protection, reverse polarity defense, and high-current handling. Our modules deliver dependable performance even in unstable voltage conditions.

Weather-sealed box builds, cable harnessing, and connectorization for field-ready deployment. All harnesses are labeled, strain-relieved, and tested for continuity and insulation resistance.

Temperature cycling, humidity testing, and thermal shock simulations ensure devices remain stable across wide operating ranges. We log all test data for traceability and post-market analysis.

We provide RMA handling, repair, and refurbishment programs to extend product life and reduce total cost of ownership for OEMs and distributors.

Foxtronics EMS combines technical precision with field-tested durability. Our engineers understand the environments where agricultural equipment operates and build electronics that can withstand them.

We partner with OEMs to improve manufacturability, reduce service issues, and sustain production continuity through smart component planning and supply chain resilience. Our mission is simple — help you deliver electronics that never stop working when the work matters most.

We uphold strict quality, safety, and compliance standards backed by advanced inspections, thorough testing, and globally recognized certifications to ensure product reliability and performance.

Every product undergoes rigorous in-line inspections, functional testing, and quality control processes at every stage of production to guarantee consistency and precision.

Foxtronics EMS maintains internationally recognized certifications that reflect our dedication to quality management and regulatory compliance across multiple industries:

With decades of experience and industry certifications, Foxtronics EMS supports leading innovators in demanding sectors, delivering reliable PCB assembly for mission-critical products. Our certified quality systems, advanced manufacturing, and engineering expertise ensure we meet the unique technical requirements of every industry we serve.

Foxtronics EMS combines precision, reliability, and scalability to deliver high-performance PCB assembly solutions. With decades of experience, advanced facilities, and engineering expertise, we add value across every stage of your product’s lifecycle.

With over 116 years of combined experience, Foxtronics EMS serves industries such as aerospace, medical, and industrial. Our AS9100, ISO, and ITAR certifications ensure compliance with the highest quality and regulatory standards, allowing us to meet the demands of mission-critical applications.

From initial design to final delivery, we offer complete lifecycle support. Our in-house engineering team provides DFM and early design consultation to optimize manufacturability, reduce risk, and accelerate time-to-market—ensuring a smooth transition from concept to scalable production.

Foxtronics EMS provides fully managed turnkey solutions, including component sourcing, SMT and through-hole assembly, box builds, and testing. This approach simplifies supply chains, reduces vendor dependency, and ensures consistent quality at every stage.

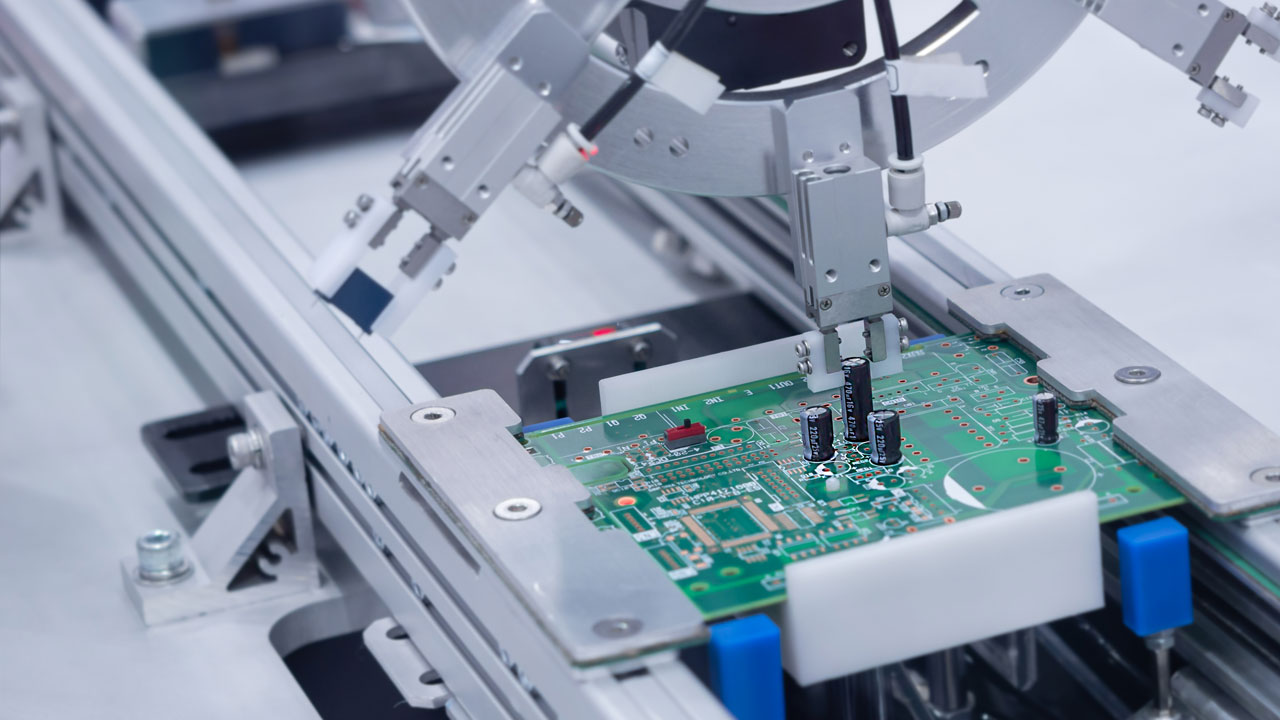

Our state-of-the-art facilities are designed to handle complex PCB assemblies with exceptional precision and reliability. Automated systems, high-speed SMT lines, and rigorous process controls ensure consistent quality and scalability, supporting the most intricate and demanding production requirements.

Quality assurance is built into every step of our process. We utilize AOI, X-ray inspection, in-circuit, and functional testing to detect defects early and ensure long-term reliability. Our inspection protocols align with IPC and AS9100 industry standards.

With flexible production and streamlined workflows, we offer rapid prototyping and efficient scaling for diverse production needs. Whether for low-volume prototypes or high-volume runs, our responsive team ensures fast, reliable delivery without sacrificing quality.

Our facilities are purpose-built for precision and flexibility, supporting everything from quick-turn prototypes to high-volume PCBA production. With dedicated areas for assembly, inspection, and testing, every process runs under controlled workflows to ensure consistent quality at scale.

Find answers to common questions about our rugged PCB assemblies for agriculture, off‑highway equipment, and smart farming—built to ensure durability, reliability, and performance in tough field conditions.

We build controllers, telemetry units, GPS systems, lighting modules, and power boards used in tractors, implements, and stationary equipment.

Through conformal coating, potting, sealed connectors, and vibration-resistant mounting — plus environmental validation that simulates field conditions.

Yes. We provide rapid prototyping and pilot builds that replicate full-scale production processes, allowing faster validation and refinement.

Absolutely. Our scheduling and inventory management systems adapt to seasonal demand, ensuring timely deliveries during peak farming cycles. For a deeper look at how we manage sourcing, risk, and continuity across production cycles, explore our EMS supply chain strategy article.

Yes. We manage structured RMA, repair, and spare-part programs that help OEMs extend product lifecycles and support end-users efficiently.