Aftermarket services are a critical extension of electronics manufacturing, ensuring that products remain functional, reliable, and supported throughout their lifecycle. These services help manufacturers reduce field failures, control warranty costs, and protect their brand reputation by providing timely repairs, rework, and refurbishment.

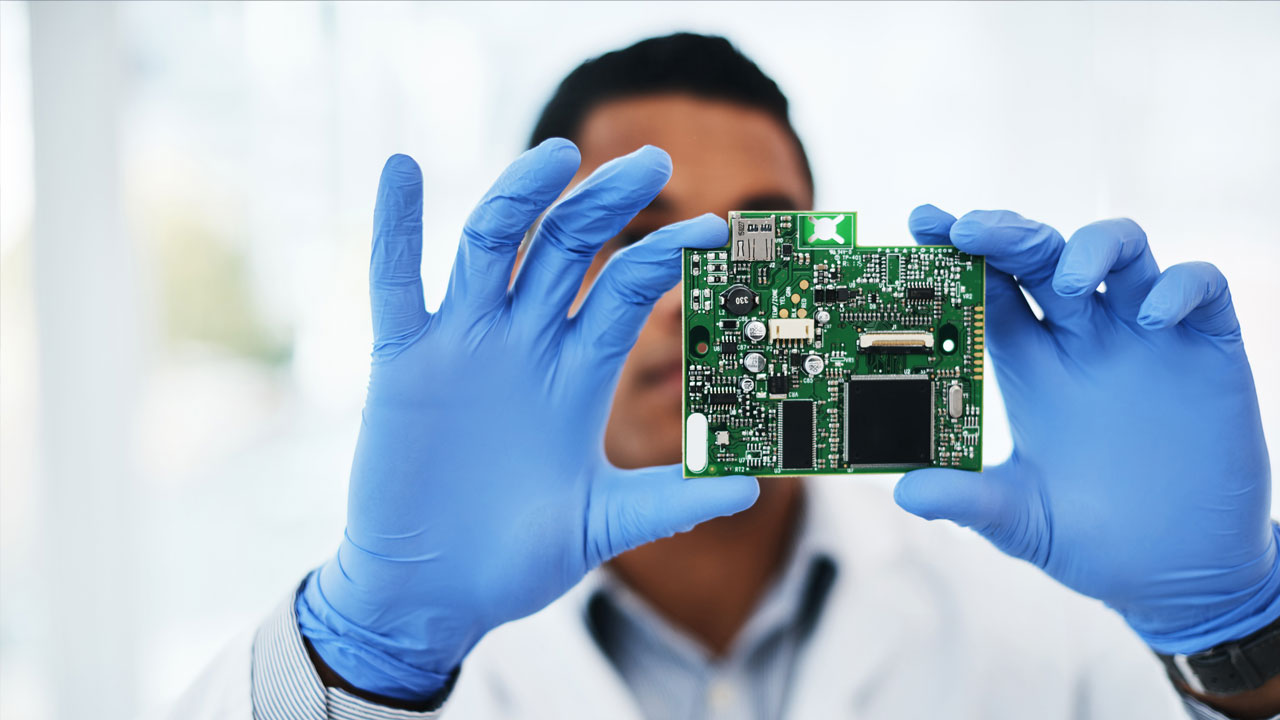

At Foxtronics EMS, aftermarket support is designed to deliver value long after the initial PCB assembly and production phases are complete. Whether it’s managing RMA returns, performing precise component-level repairs, or upgrading assemblies for extended use, our approach focuses on minimizing downtime and maximizing product life. Full traceability, detailed reporting, and quality assurance are built into every step of the process to give customers confidence in the continued performance of their electronics products.

These aftermarket services also support product lifecycle extension and sustainability efforts. By refurbishing, upgrading, or repairing existing assemblies, OEMs can reduce electronic waste, defer costly redesigns, and keep legacy systems operational. As the demand for reliable, long-life electronics grows in industries like medical, industrial, and commercial sectors, comprehensive aftermarket services become a vital part of overall product strategy.