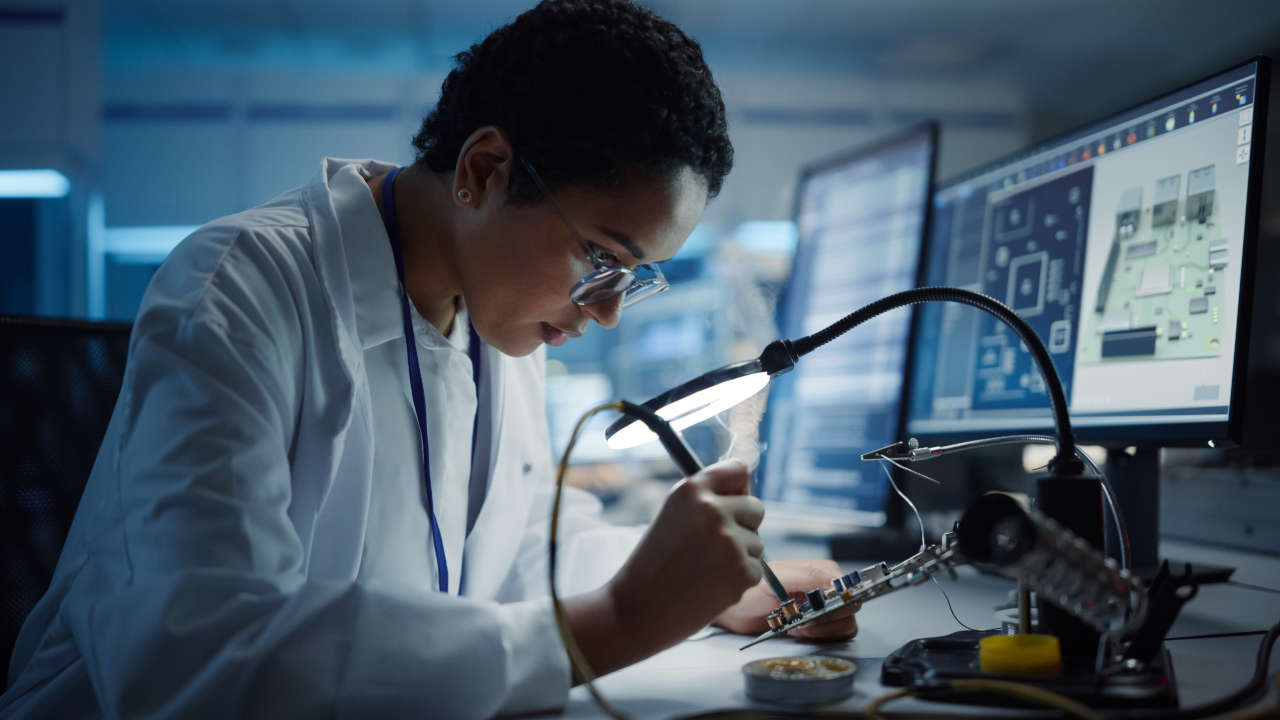

PCB design enablement is where innovation meets feasibility. Unlike standard boards, advanced custom designs address unique performance goals, mechanical constraints, or integration challenges that off-the-shelf layouts cannot accommodate. These capabilities are essential in high-stakes sectors where every millimeter of space and every signal matters.

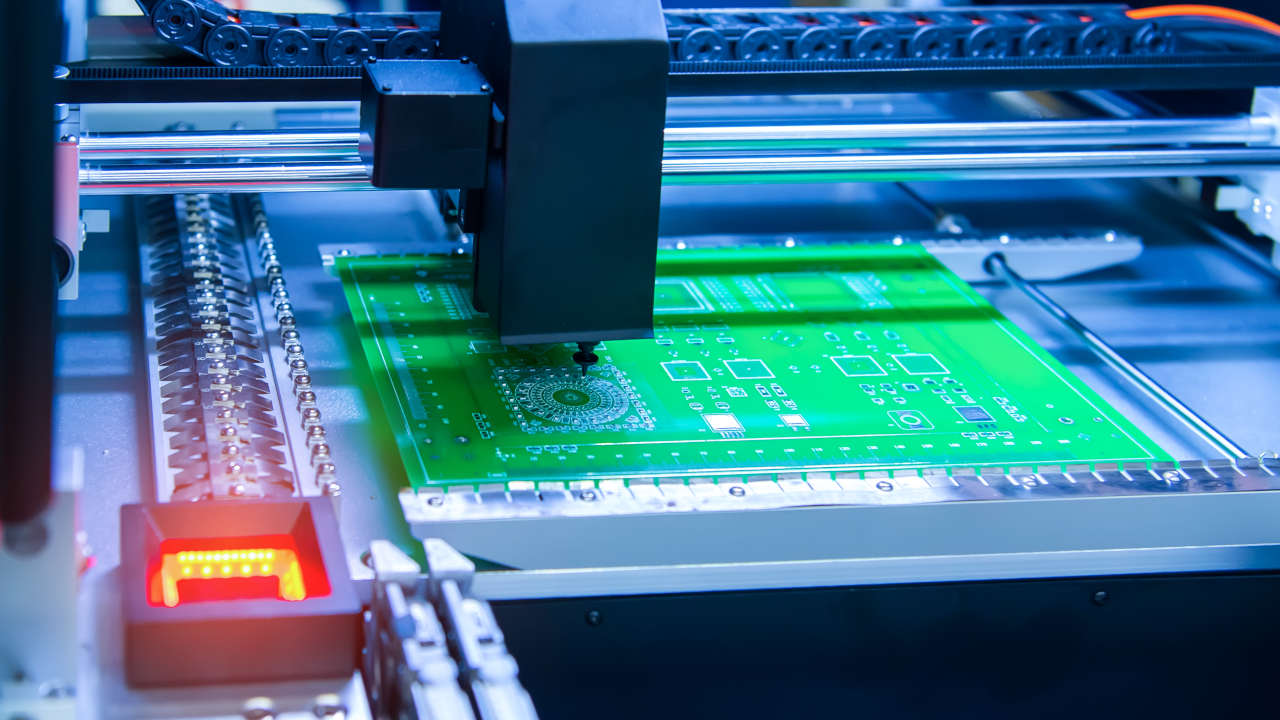

We collaborate closely with your design engineers and trusted partners to ensure layouts meet your application requirements. Through design for manufacturability (DFM) feedback, assembly insights, and signal integrity support, we help optimize designs for functionality, manufacturability, and performance.

Whether supporting a new layout, optimization, or redesign, we partner with your team using advanced ECAD tools and IPC-compliant practices to help reduce iterations and accelerate time to market. From high-speed digital interfaces and RF considerations to thermal control and stack-up review, we ensure your PCB is ready for seamless assembly.