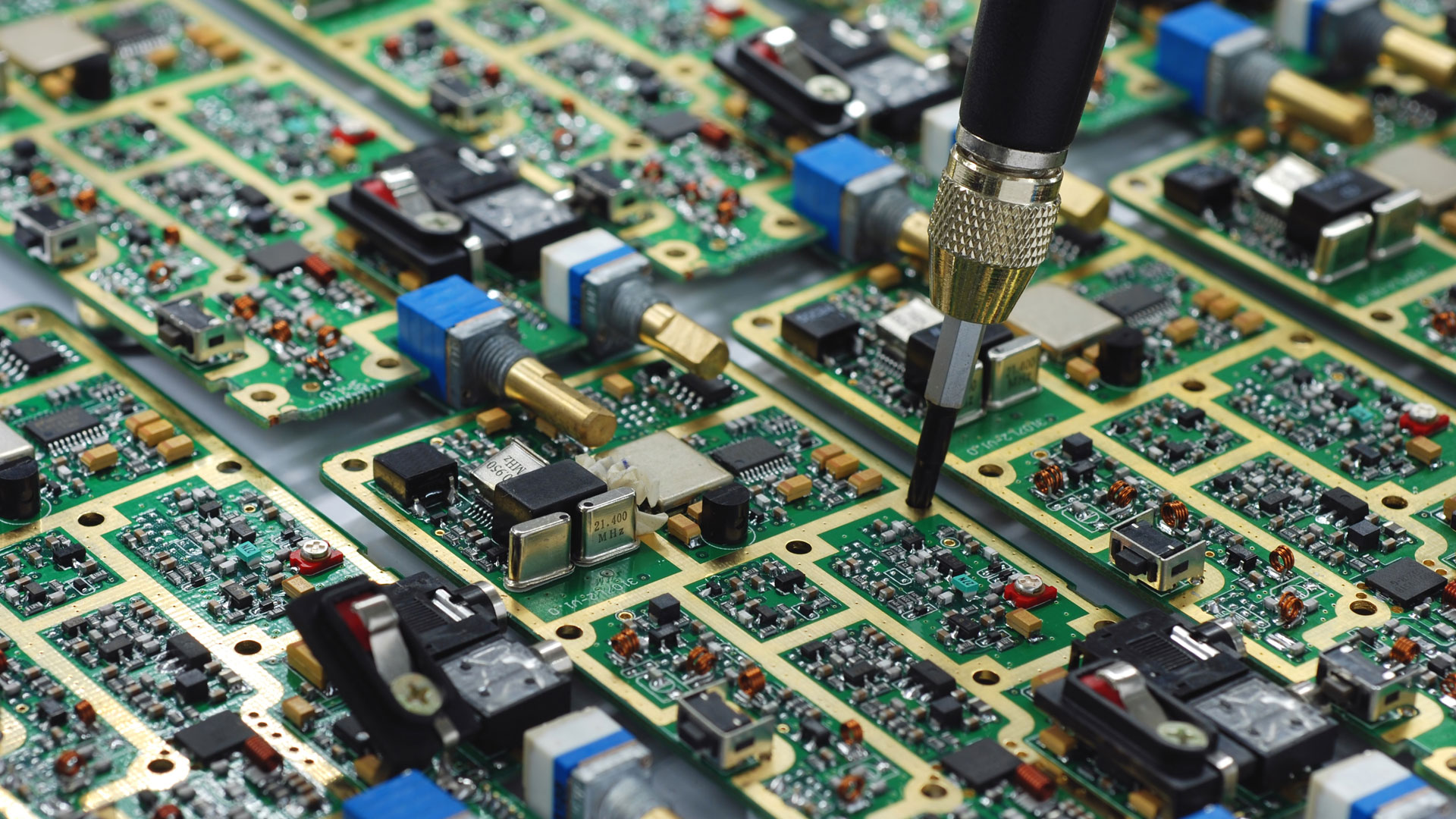

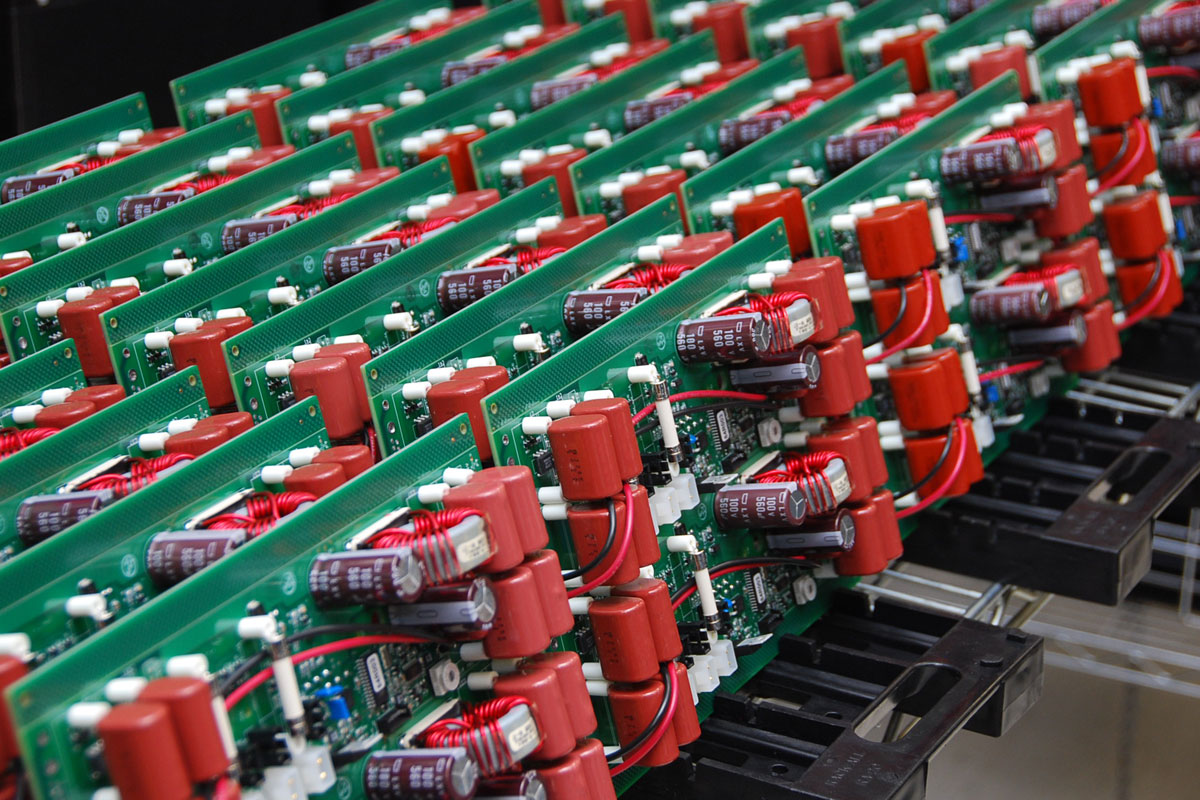

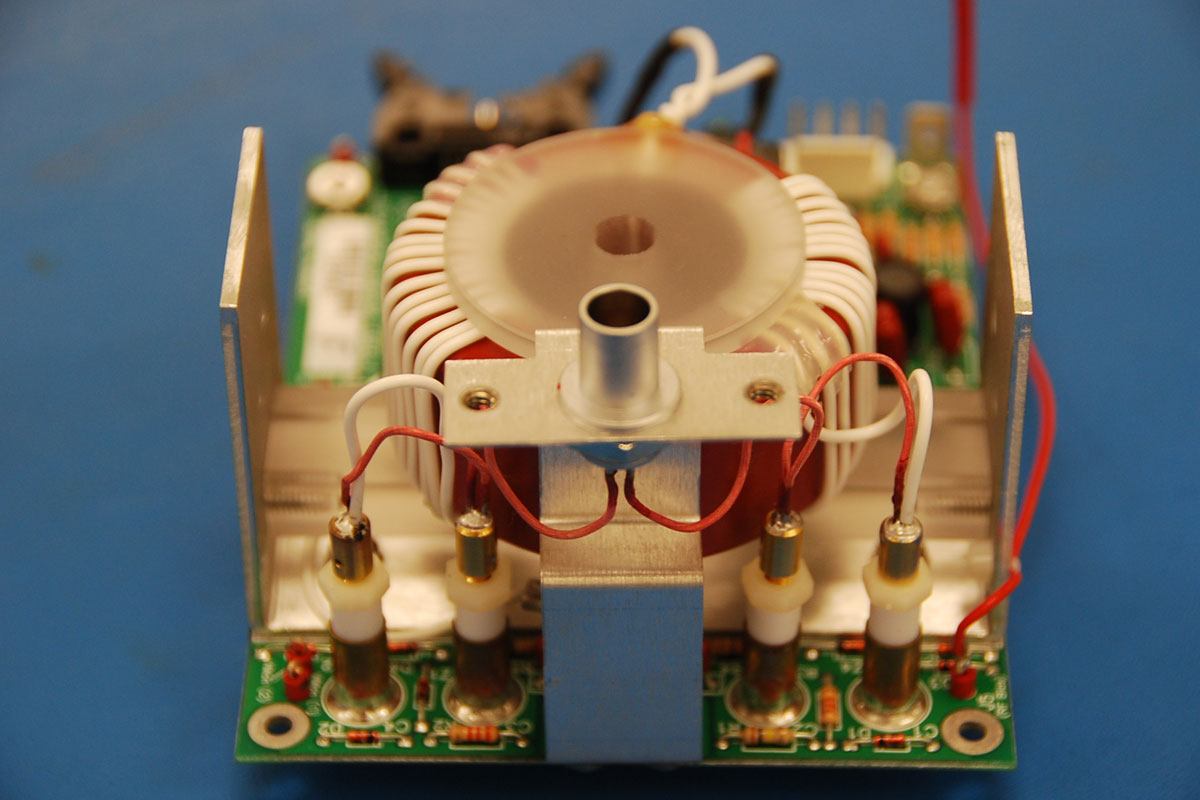

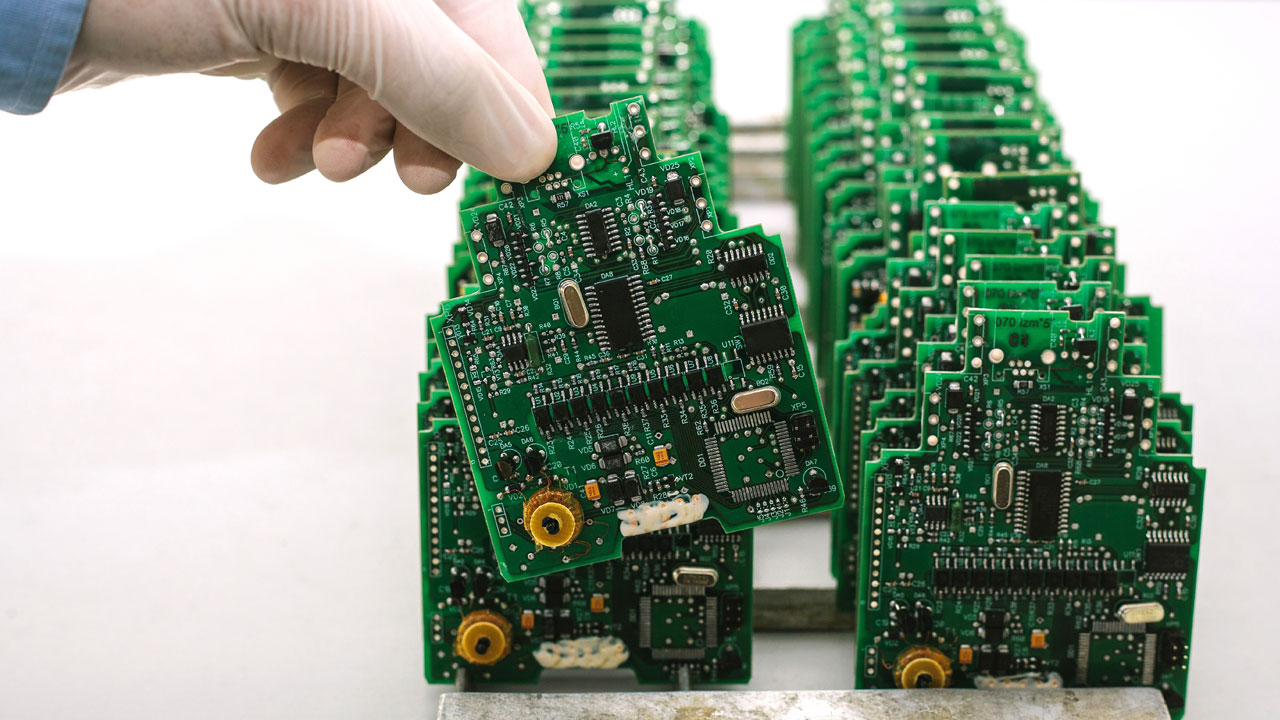

Through-hole assembly remains the gold standard for applications demanding exceptional mechanical durability and long-term reliability. Foxtronics EMS leverages both manual and automated wave and selective soldering techniques to ensure every component is firmly anchored and capable of withstanding harsh environments ideal for defense systems, and industrial machinery.

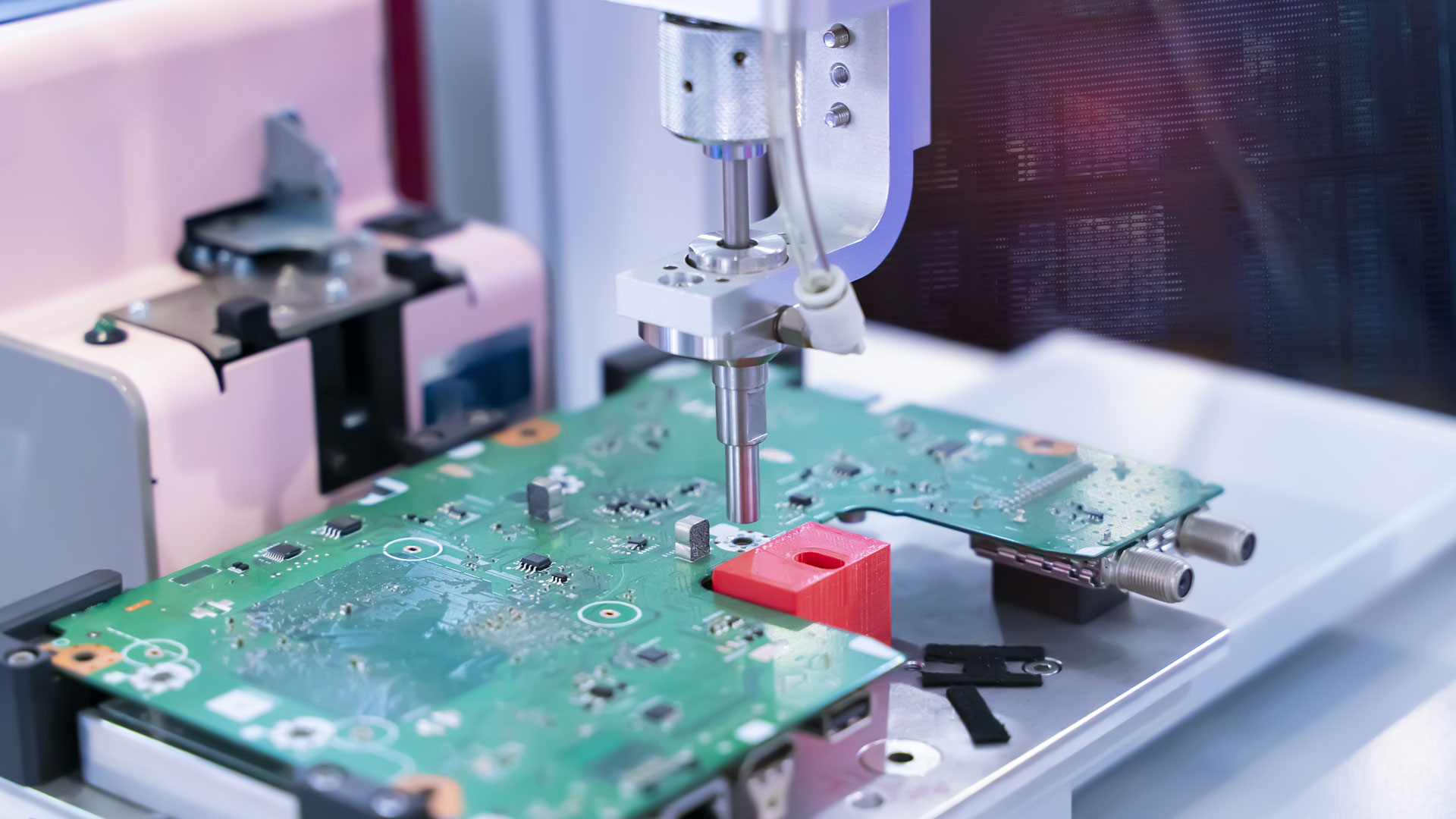

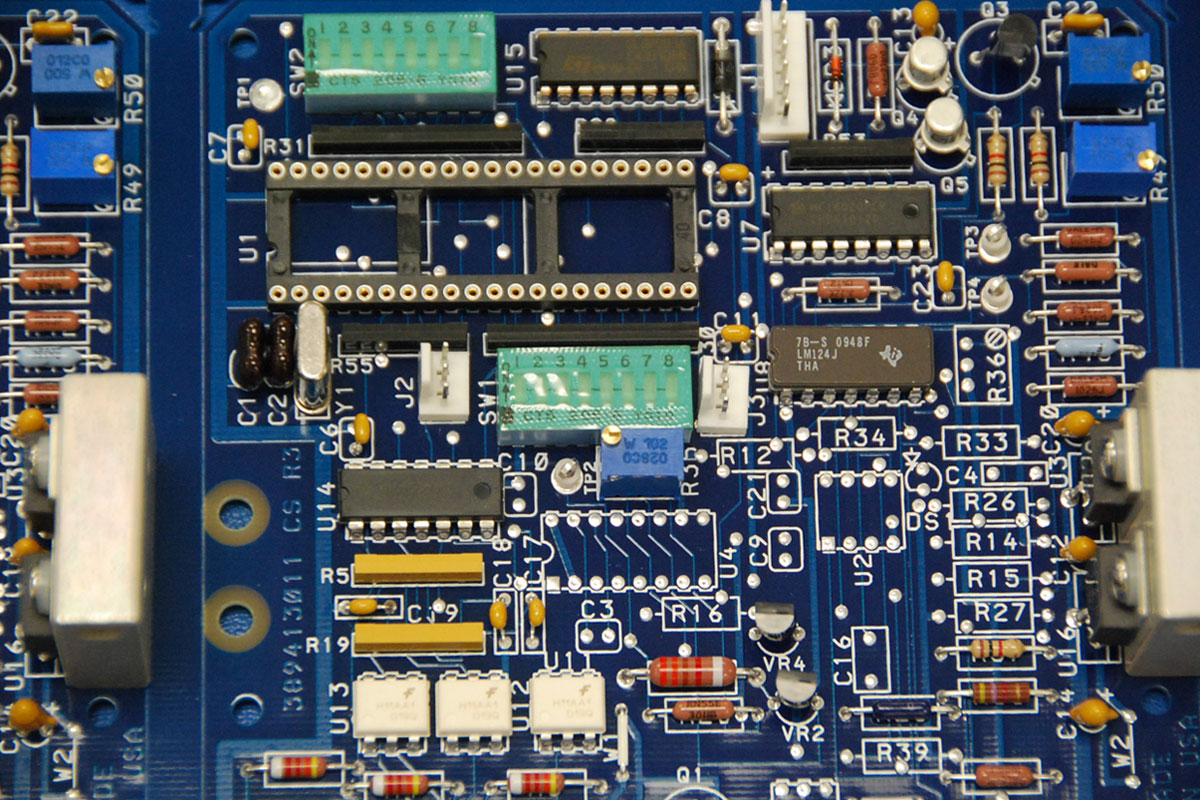

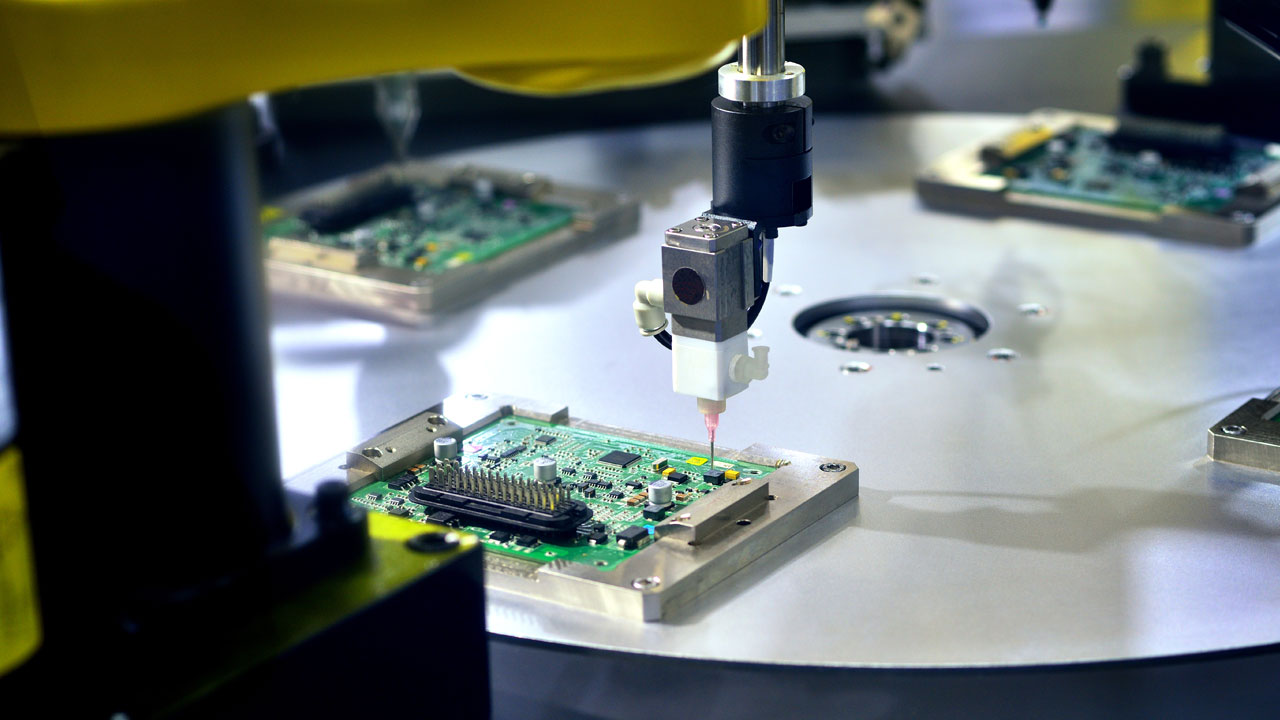

Our U.S.-based PCBA manufacturing facilities combine IPC-qualified technicians, precision tooling, and robust process controls to deliver consistent solder joint integrity across mixed-technology boards. Whether you require high-mix, low-volume runs or larger production batches, our flexible workflows adapt to your volume, complexity, and regulatory requirements, without sacrificing quality or lead time.

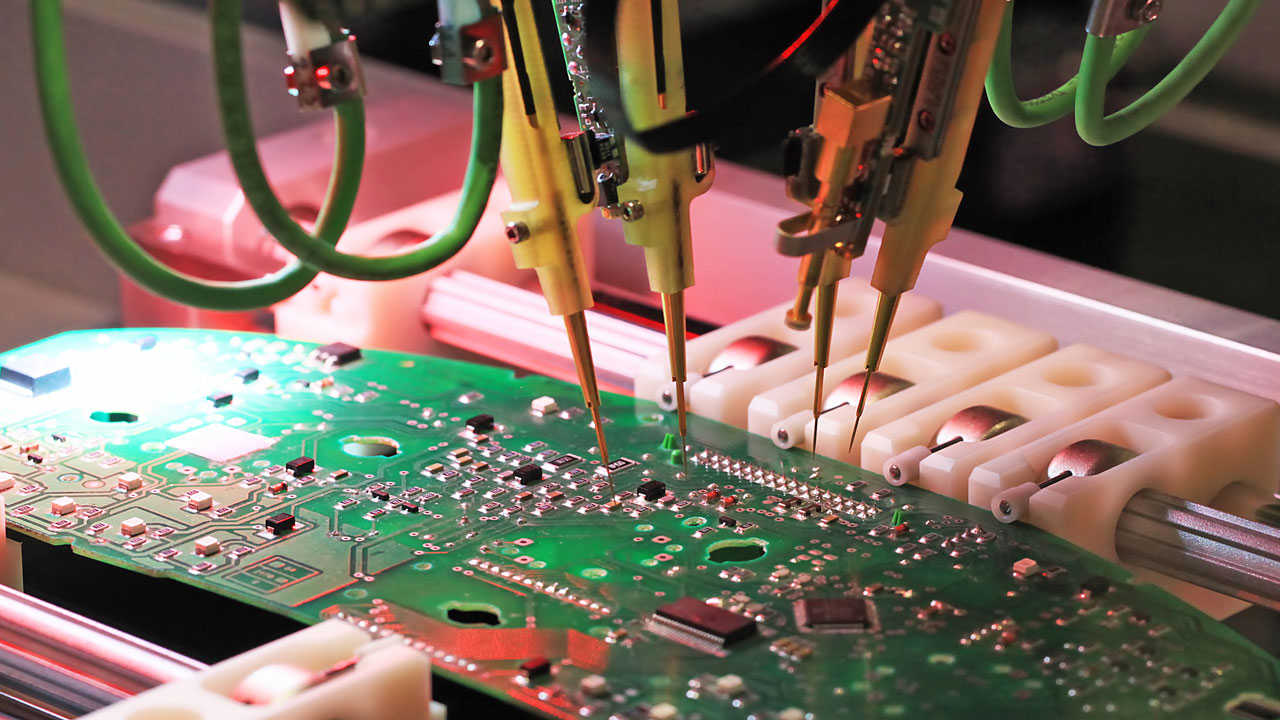

From initial DFM reviews to final inspection and functional testing, our through-hole PCB assembly services integrate seamlessly with SMT, box build, and turnkey PCBA solutions. By maintaining tight traceability and adhering to industry standards such as IPC-610 and J-STD-001, we help you achieve superior performance and compliance for mission-critical electronic products.